Centering adjustment method for equipment output shaft and product input shaft

A technology of centering adjustment and output shaft, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve problems such as complicated operation, and achieve the effect of simple calculation, clear principle and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

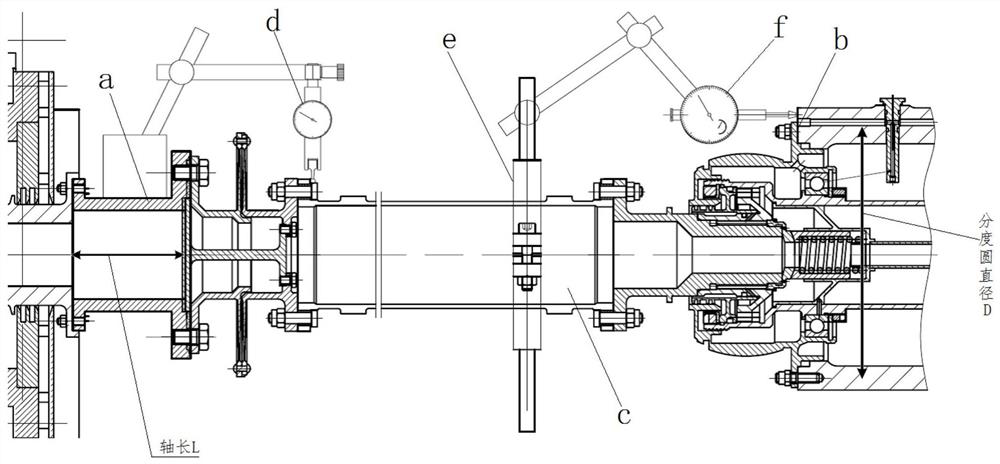

[0039] In order to further describe the content of the present invention, the following will be described in conjunction with the schematic diagram,

[0040] Such as figure 1 As shown, a, the output shaft of the high-speed gearbox, b, the seal installation surface of the main minus input shaft, c, the diaphragm-gear coupling, d, the first dial indicator, e, the dial indicator bracket, f, the first dial indicator 200 gauge,

[0041] When implementing centering and positioning, the above-mentioned centering auxiliary mechanism is installed, wherein, the fixed end of the table seat of the first dial indicator d is fixed at the output shaft a of the high-speed gearbox; the head of the first dial indicator d is in contact with At the end face of the diaphragm shaft, the dial indicator support e is installed at the diaphragm-gear coupling c, and the dial indicator support e is connected to the second dial indicator f; the head of the second dial indicator f is in contact with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com