Ultrahigh vacuum sample transfer cavity

An ultra-high vacuum and sample transfer technology, which is applied to the analysis of materials and instruments, can solve the problems of unavoidable open cavity sampling operation steps, complicated operation, and contaminated samples, and achieve the effect of simple structure, small volume, and pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

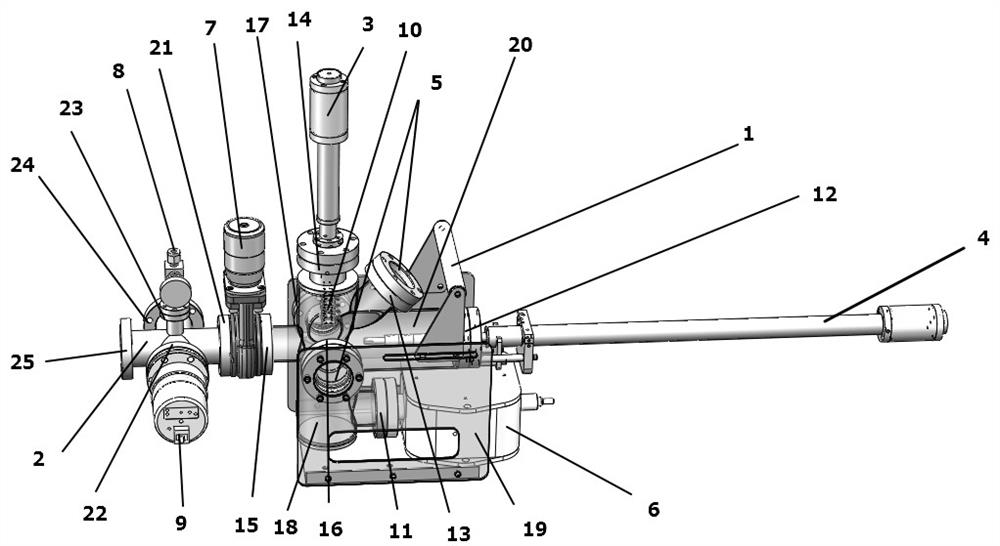

[0022] As shown in the figure, the present invention provides a portable device for transferring samples between different ultra-high vacuum systems.

[0023] figure 1 A perspective view of the overall structure according to an embodiment of the present invention is shown. In this embodiment, the sample transfer chamber consists of a transfer chamber 1, an auxiliary chamber 2, a sample transfer magnetic rod 3, a swing magnetic rod 4, an observation window 5, an ion pump 6, a gate valve 7, an air intake valve 8, and a vacuum gauge 9 1. The sample stage 10 is used to connect the ultra-high vacuum system for sample transfer. The ion pump 6 is in sealing connection with the first flange 11, the swinging magnetic rod 4 is in sealing connection with the second flange 12, the observation window 5 is in sealing connection with the third flange 13, the sixth flange 16, and the seventh flange 17. The sample magnetic rod 3 is in sealing connection with the fourth flange 14, the flapper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com