Cloud computing and edge computing combined production control system

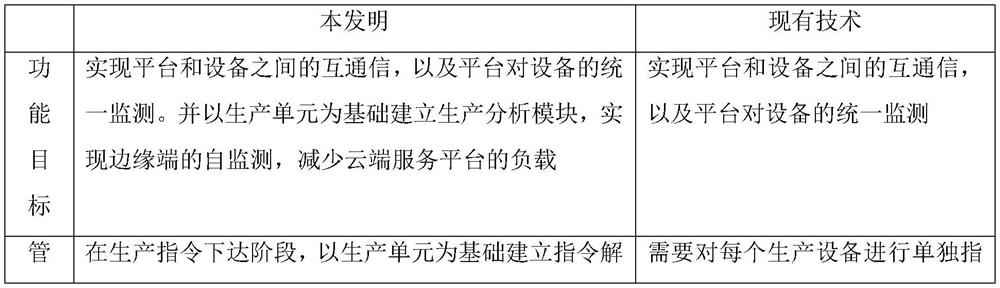

A technology of production control and edge computing, applied in the field of cloud computing, can solve problems such as monitoring lag, high communication pressure, and effective use of unfavorable early warning information, and achieve the effect of reducing monitoring pressure and solving monitoring lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

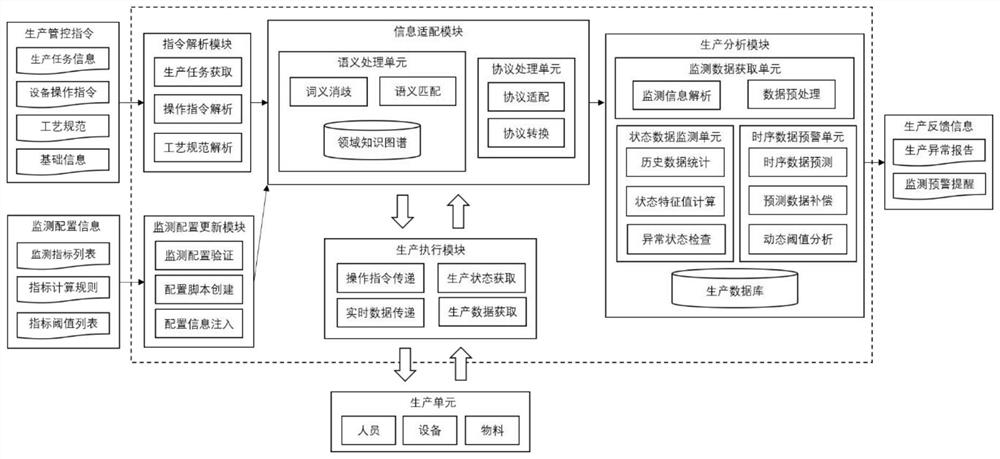

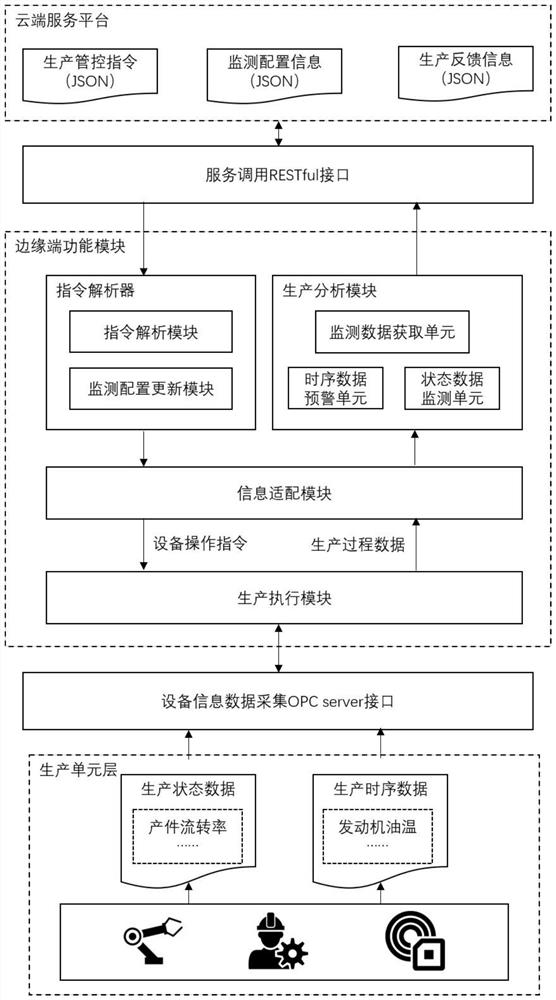

[0027] Such as figure 1 As shown, this embodiment relates to a production control system combining cloud computing and edge computing, including: an instruction analysis module, a monitoring configuration update module, an information adaptation module, a production execution module, and a production analysis module, wherein: the instruction analysis module Receive production control instructions from the cloud service platform and perform content analysis to obtain production tasks, operation instructions and process specifications; the monitoring configuration update module receives monitoring configuration information from the cloud service platform for adjusting and explaining production monitoring targets, and analyzes After the monitoring configuration information is released, its validity and applicable equipment will be verified, and the generation and injection of relevant execution scripts will be completed based on the configuration information; the information adapt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com