Stepping motor stator and stepping motor with same

A stepper motor, motor stator technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of large back EMF harmonics of the motor, large vibration noise of the motor, affecting the smooth operation of the motor, etc., to reduce the back EMF Harmonic effect, reducing vibration and noise, improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

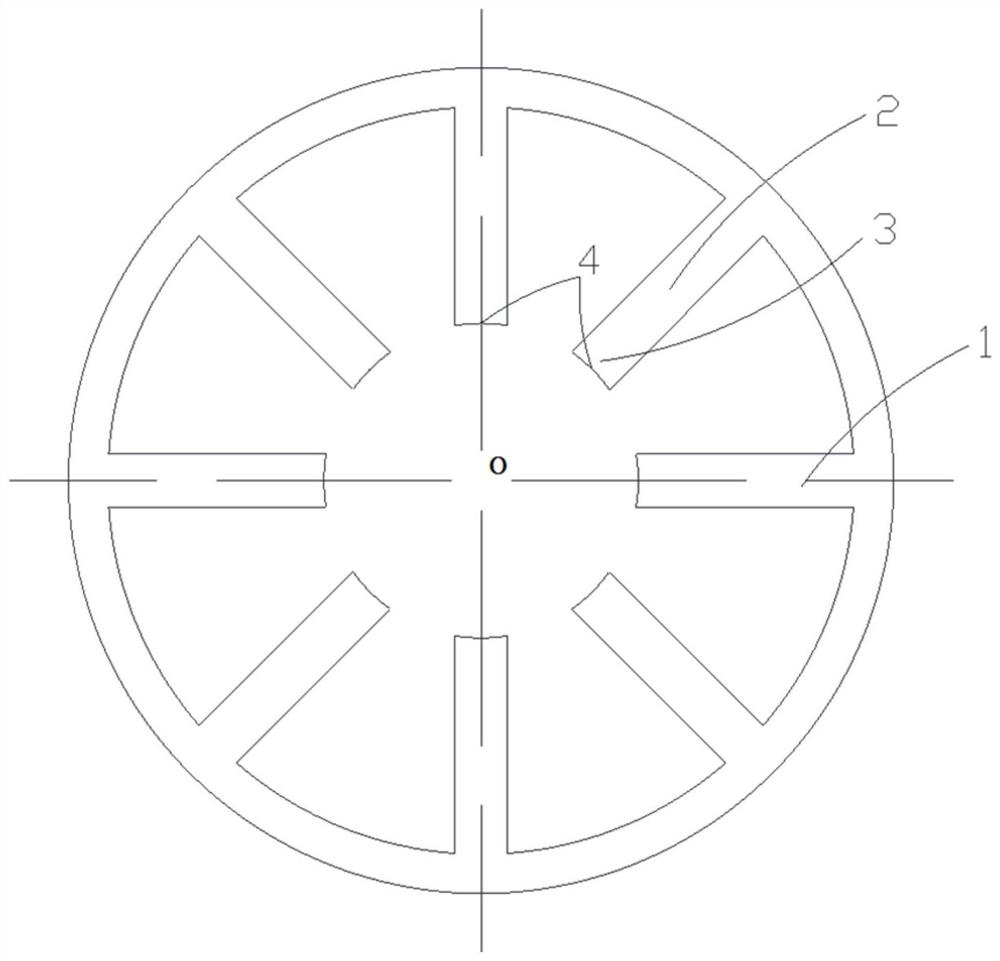

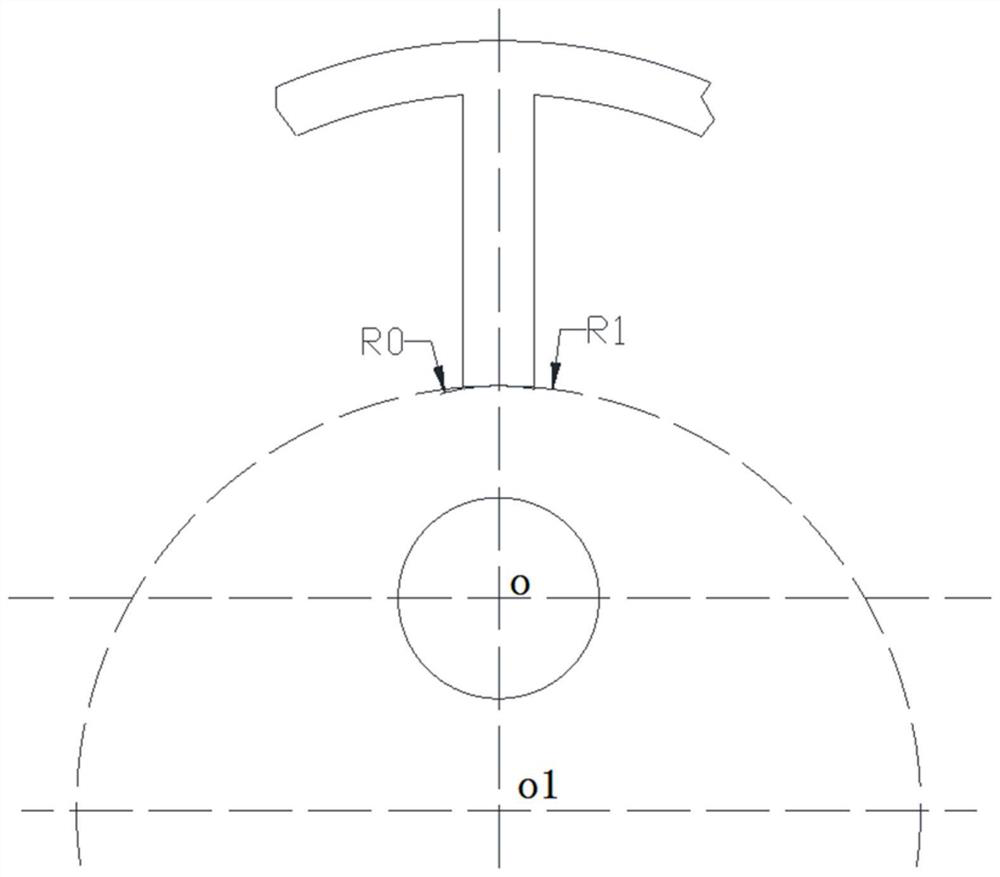

[0025] like Figure 3-4 As shown, a stator of a stepping motor includes a stator core 1, the stator core 1 is evenly distributed with several stator main poles 2 along the inner diameter of the stator, and the ends of the stator main poles 2 are connected with a number of stator teeth 3 , the number of the stator teeth 3 is the same as that of the stator main poles 2 , and the stator tooth outline of the stator teeth 3 is the tooth arc cutting outline 5 or the tooth straight outline 6 .

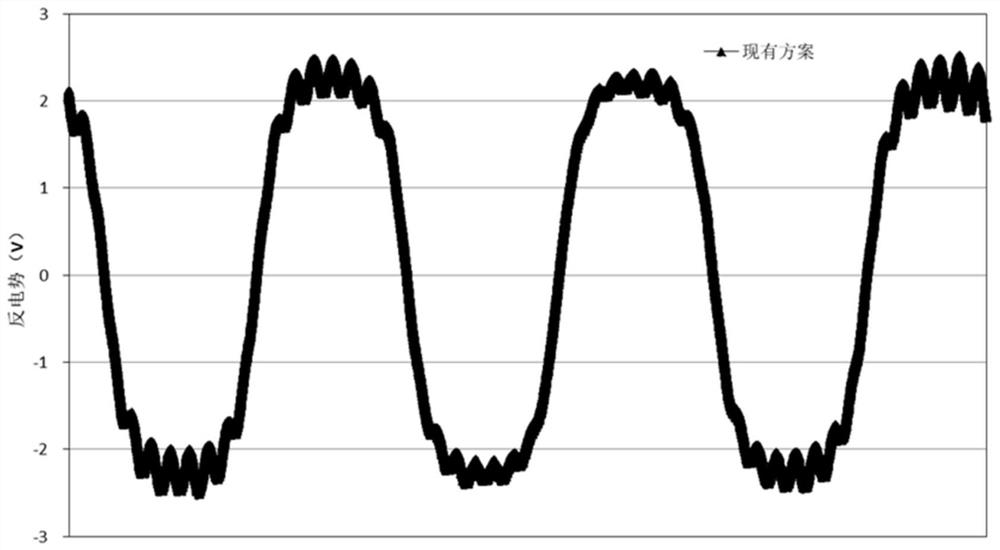

[0026] In the stepping motor with the same number of poles and the same number of teeth, the present invention performs arc cutting or straight line processing on the tooth contour of the motor, such as image 3 As shown, the air gap between the stator and rotor of the motor is made uneven. Compared with the existing scheme, the harmonics of the motor back EMF of the present invention can be greatly improved, specifically as Figure 5 shown.

[0027] The radius R1 of the tooth arc cutting c...

Embodiment 2

[0031] like Figure 3-4 As shown, a stepper motor with a stator, including a motor rotor and a motor stator in Embodiment 1, reduces the back EMF harmonics of the motor, reduces the vibration and noise of the motor, and improves the motor stator by improving the motor stator. smoothness of operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com