Rigidity-adjustable rear torsion beam suspension

A rigidity and torsion beam technology, applied in suspension, interconnection system, transportation and packaging, etc., can solve problems such as beam cracks, affecting the stability and safety of the whole vehicle, and high stress requirements on beams, so as to avoid deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

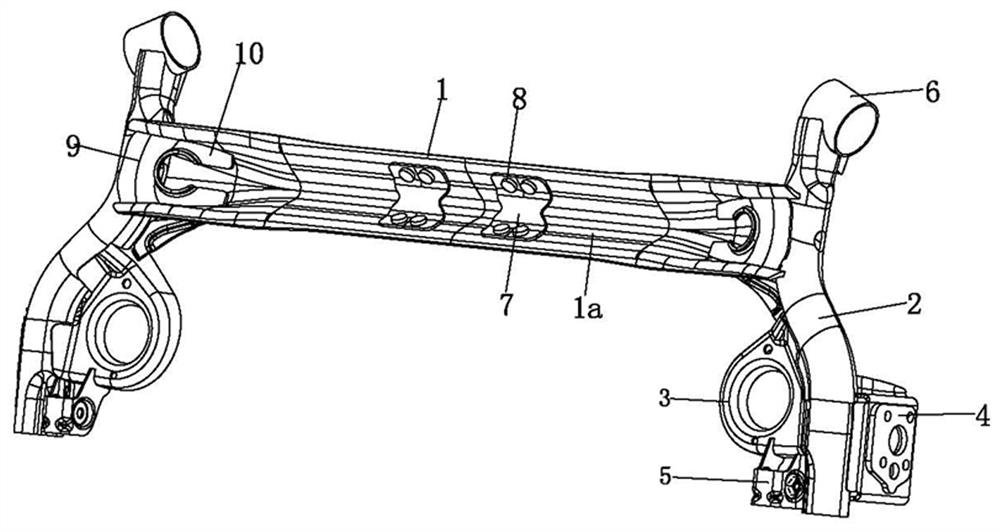

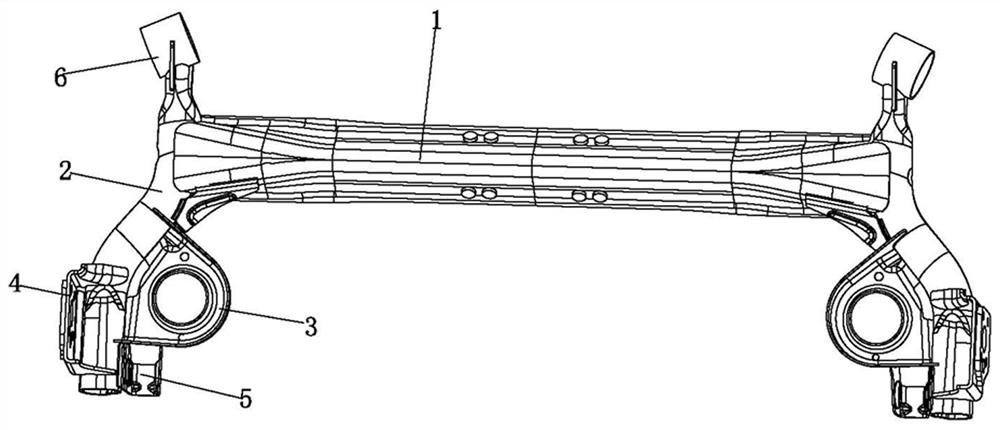

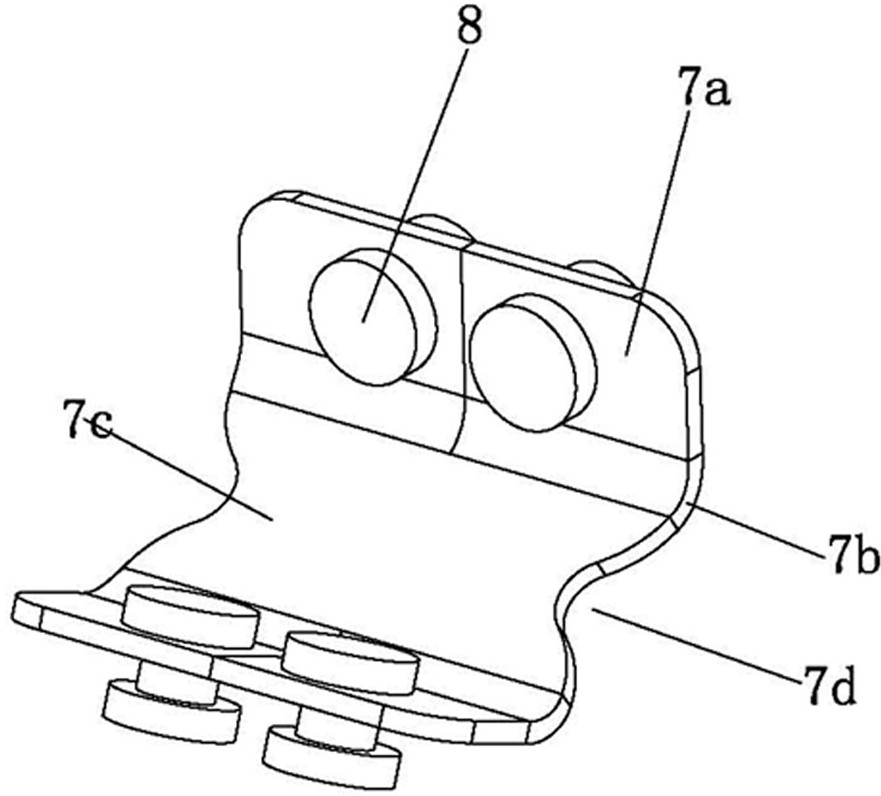

[0022] like Figure 1 to Figure 4 , the rear torsion beam suspension with stiffness adjustment of the present invention comprises a crossbeam 1, a longitudinal arm 2, a spring seat 3, a tire support 4, a shock absorber support 5, and a rear axle support 6, and the two ends of the crossbeam 1 are respectively fixed with The longitudinal arm 2 and the spring seat 3 are respectively fixed to the crossbeam 1 and the longitudinal arm 2, the tire support 4 is fixed to the longitudinal arm 2, the shock absorber support 5 is respectively fixed to the longitudinal arm 2 and the spring seat 3, and the rear axle support 6 is fixed to one end of the trailing arm 2,

[0023] Weld the prepared two longitudinal arm assemblies symmetrically to both ends of the finished beam 1, weld the spring seat 3 to the longitudinal arm assembly and the beam 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com