Relay high-voltage end adhesion processing method

A processing method and relay technology, applied in electric vehicles, electrical devices, transportation and packaging, etc., can solve problems such as insufficient charging, instantaneous overload of high-voltage circuit current, relay adhesion failure, failure to start the whole vehicle, etc., to reduce the number of vehicles The risk of stagnation on the road, the effect of ensuring safety and reducing the probability of unavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

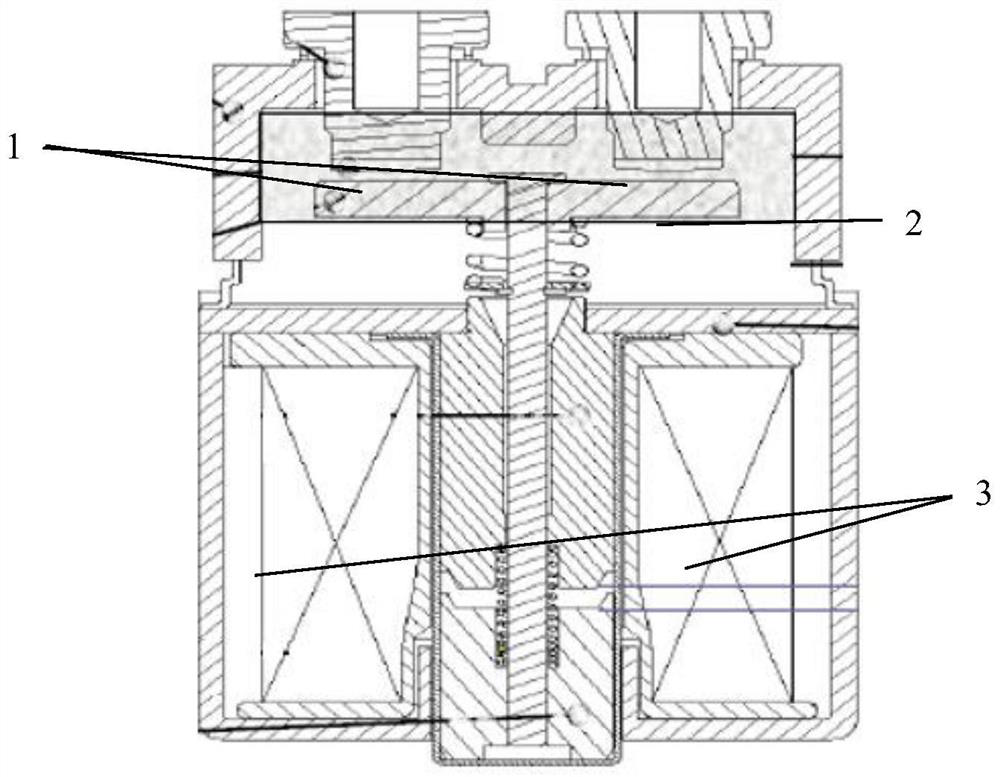

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

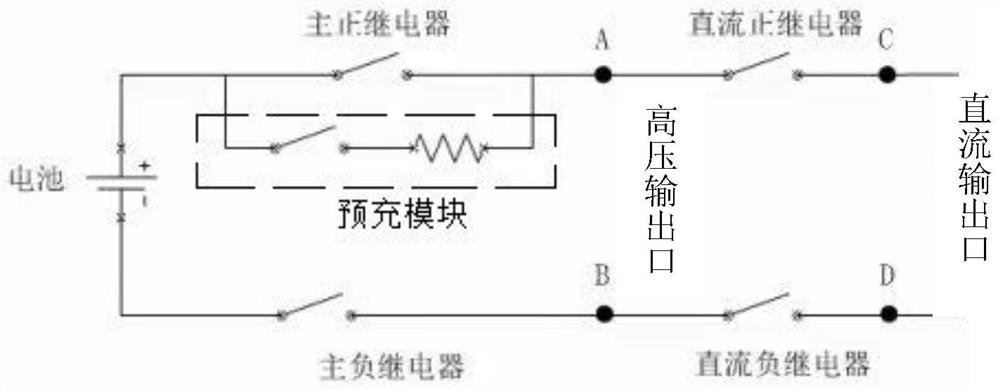

[0030] see Figure 1 to Figure 4 As shown, this embodiment discloses a method for treating adhesion at the high-voltage end of a relay, which is used in the high-voltage loop of the battery system. The high-voltage loop of the battery system includes a battery, a pre-charging module, a main positive relay, a DC positive relay, a main negative The relay and the high-voltage output port, the DC positive relay, the main positive relay, the battery, the main negative relay, the DC negative relay and the high-voltage output port are connected end to end in sequence, and the pre-charging module is connected in parallel with the main positive relay. The steps include:

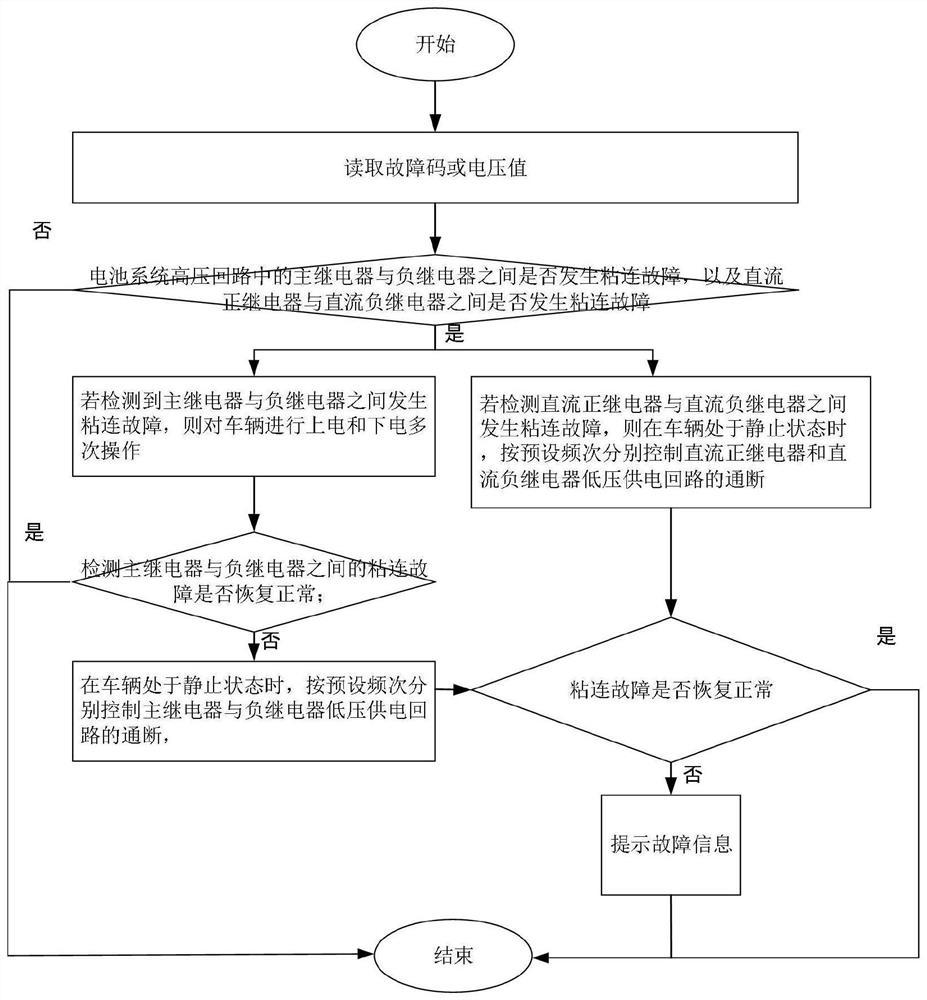

[0031] (S1) Read the fault code or voltage value to determine whether there is a sticking fault between the main relay and the negative relay in the high-voltage circuit of the batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com