Stable combined electric vehicle frame made of extruded profiles

An extruded profile and combined technology, used in motor vehicles, bicycles, bicycle accessories, etc., can solve the problems of easy rollover and general stability, and achieve the effect of avoiding safety accidents and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

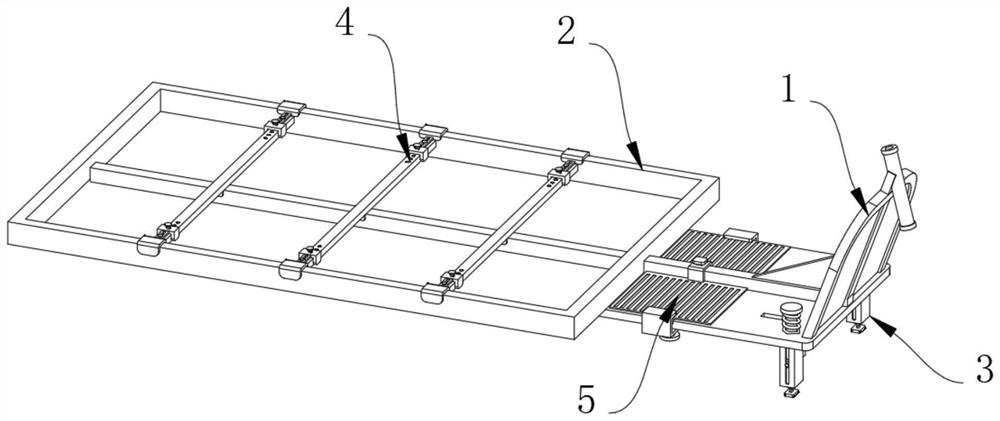

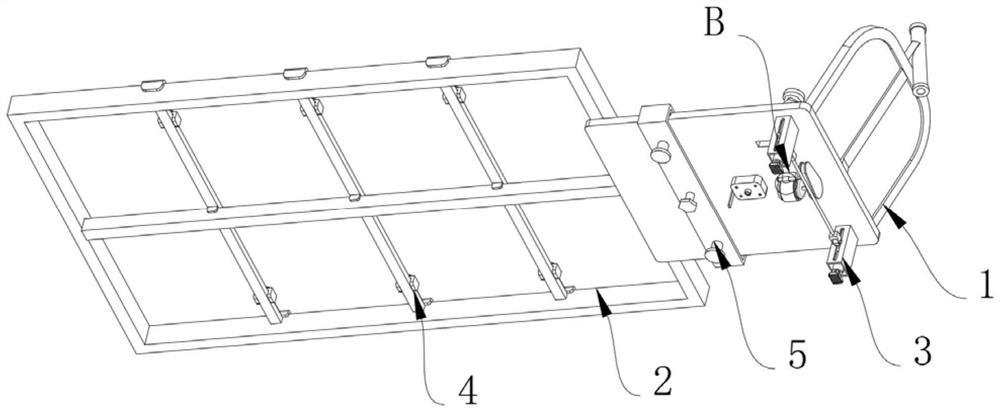

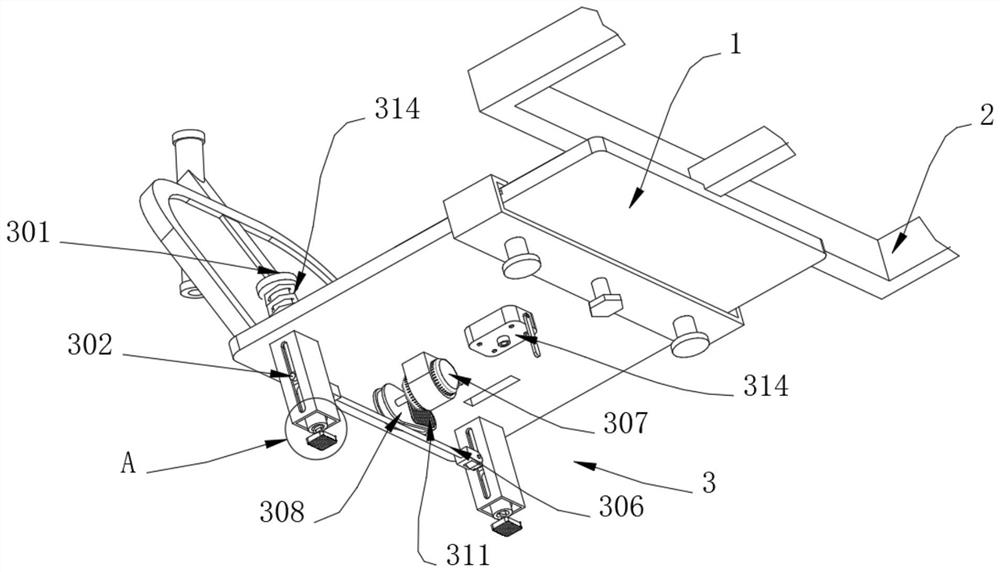

[0032] Example 1, such as Figure 1-9As shown, the present invention provides a stable combined electric vehicle frame using extruded profiles, including a stopper 1 and an inclination sensor 315, one end of the stopper 1 is welded with a shelf 2, and the cross-section of the shelf 2 is "day". ” shape, the surface of the retaining frame 1 is provided with a stabilizing structure 3, the surface of the shelf 2 is provided with an assembly structure 4, and the upper surface of the retaining frame 1 is provided with an auxiliary structure 5.

[0033] Let's talk about the specific settings and functions of its stabilizing structure 3, assembly structure 4 and auxiliary structure 5 below.

[0034] Such as image 3 and Figure 4 As shown, the stable structure 3 includes two support rods 301, and the two support rods 301 are all slidably inserted on the surface of the block frame 1. The arc surface of the support rod 301 is covered with a spring A314, and the two ends of the spring ...

Embodiment 2

[0040] Embodiment 2, on the basis of Embodiment 1, the auxiliary structure 5 includes a press button 51, which is slidably connected to the surface of the stop frame 1, and the surface of the stop frame 1 is clamped with a latch 52, and the upper end of the latch 52 slides through the press. Buckle 51, the lower surface of the two arms of press button 51 is fixedly connected with foot pad 53, the lower surface of block frame 1 is connected with screw rod 54 in rotation, and the circular arc surface of screw rod 54 is threaded with buckle plate 55, and the cross section of buckle plate 55 is The "concave" shape achieves the effect of quickly and conveniently installing the foot pad 53 on the stop frame 1, and can quickly replace the foot pad 53 after a period of use, and also facilitates disassembly and cleaning of the foot pad 53, and the block frame 1 is close to the screw rod One side of 54 is fixedly connected with two limit rods 56, and the end of the limit rod 56 away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com