Pipe belt machine and broken belt capturing device thereof

A technology of a broken belt catching device and a pipe belt machine, which is applied to the conveyor control device, conveyor, conveyor objects, etc., can solve the problems of destroying the conveyor frame, low reliability, and large kinetic energy, and achieve engineering realization. Effective cost control, quick and accurate triggering, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

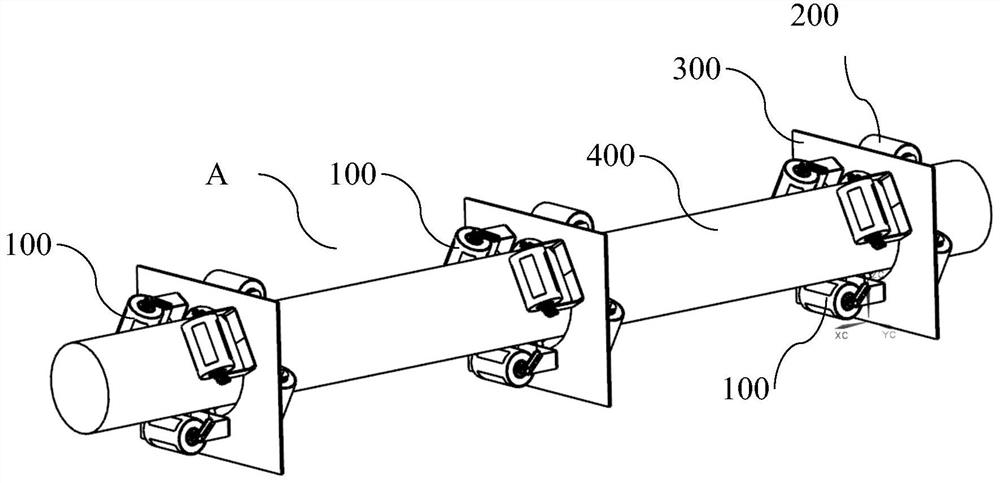

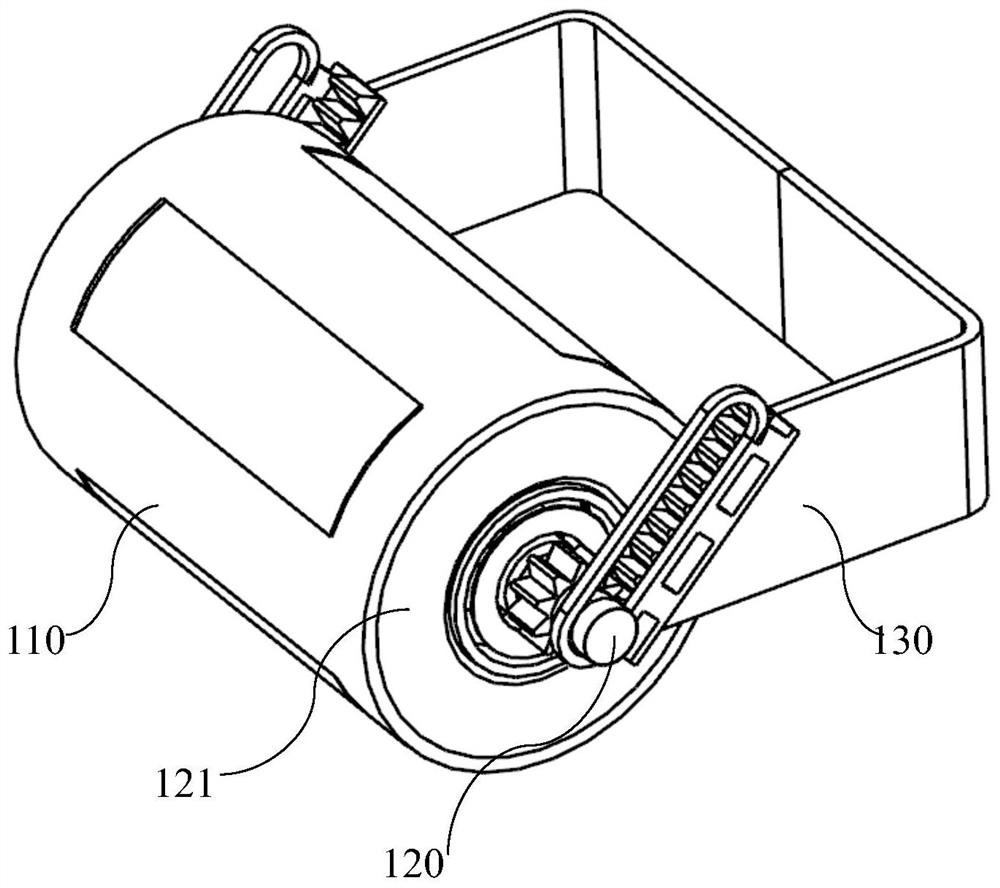

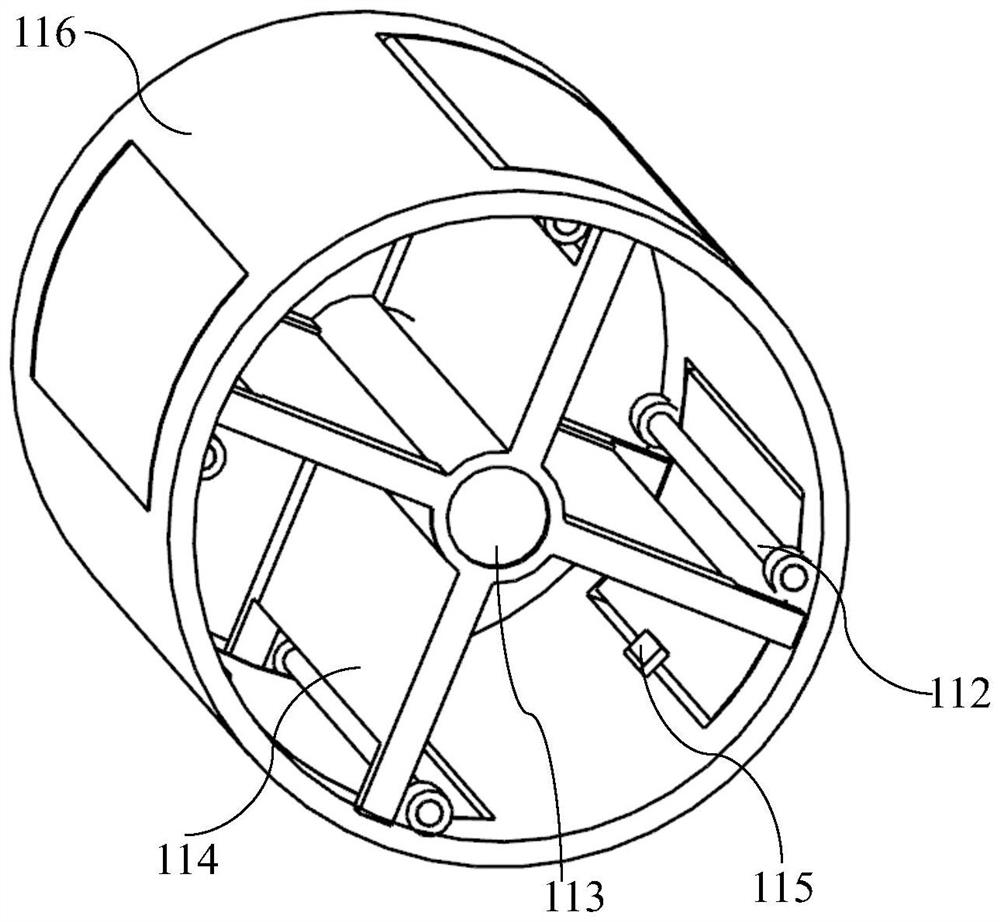

[0035] Without loss of generality, this embodiment takes the bracket 300 carrying the idler roller 200 of the belt machine shown in the figure as the basic fixed structure, and describes in detail the realization scheme of the broken belt arresting device proposed in this application. During the working process, the bracket 300 located in the loading section A or the return section B of the belt conveyor keeps the conveyor belt 400 in a cylindrical transport state through the loading idler roller 200 provided thereon. It should be understood that the specific functional structure of the carrier idler 200 is not the core invention point of the present application, and can be realized by those skilled in the art based on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com