Squeezing screen for wetted mop

A technology for wet mop and cup body is applied in the field of extrusion screen, which can solve the problem that the extrusion screen is difficult to hang reliably, and achieve the effect of saving space and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

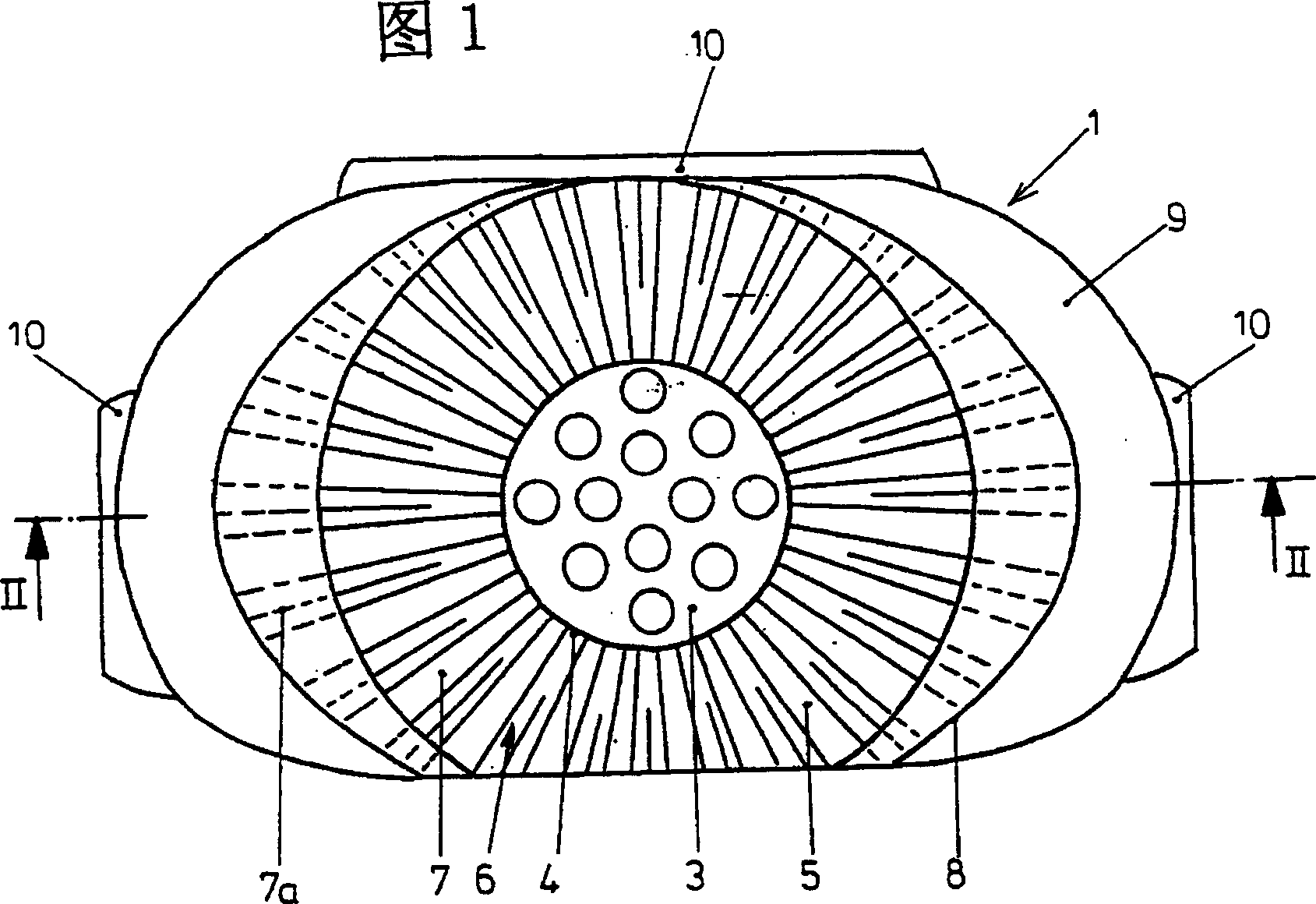

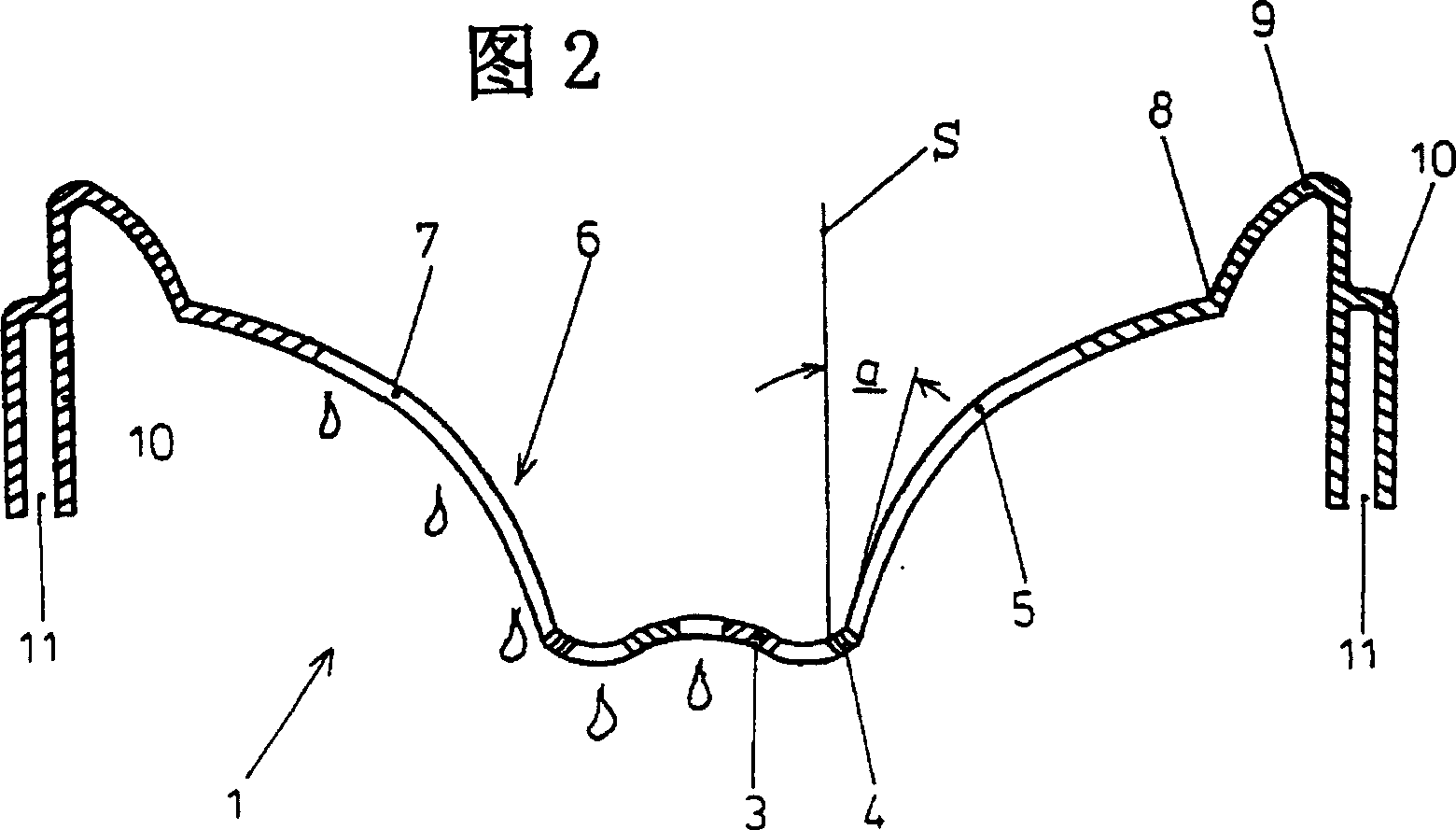

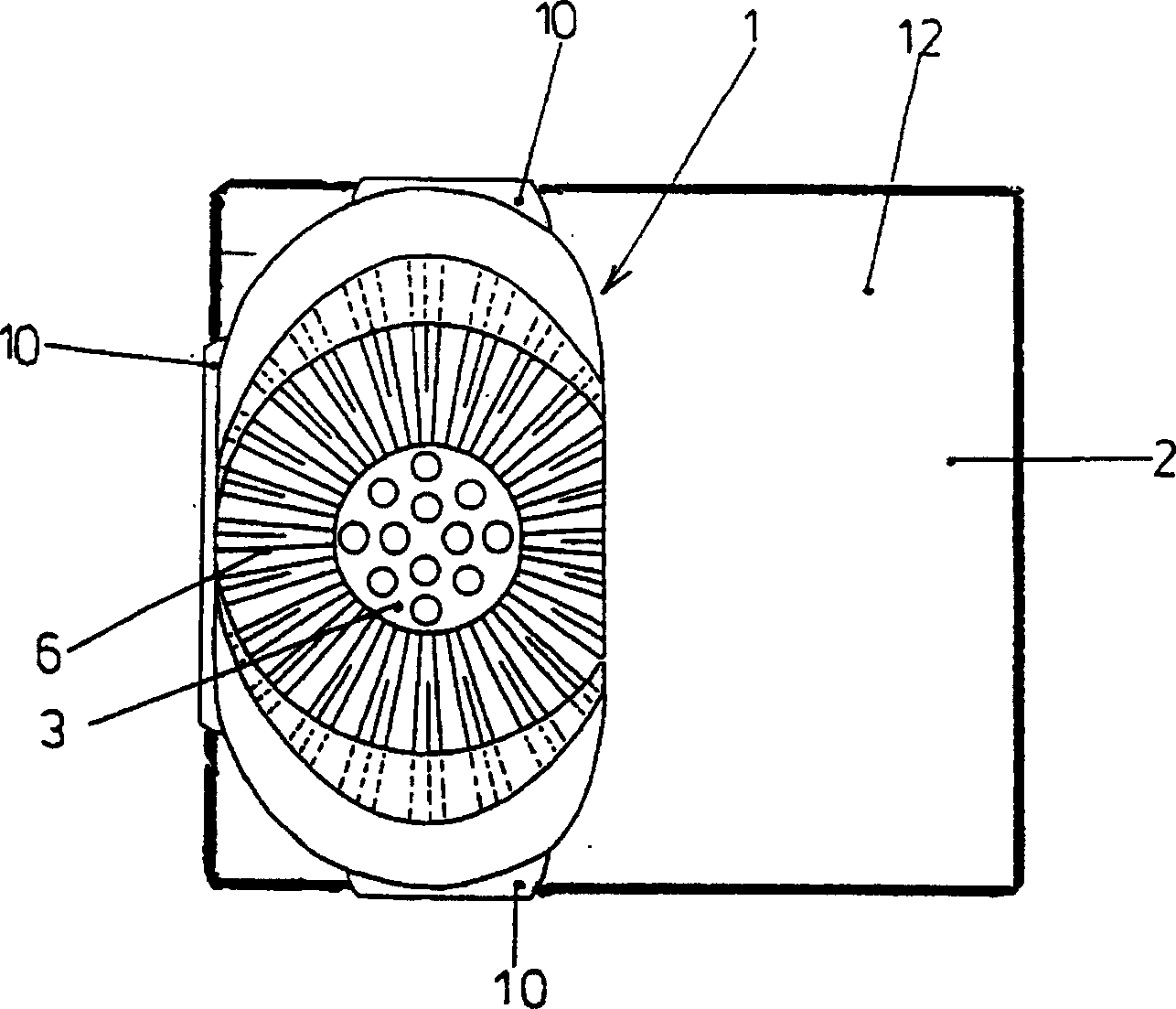

[0022] The squeeze screen 1 depicted in FIGS. 1 and 2 is produced in one piece from plastic. Provision is made to mount it on a water bucket 2 so that the water of a wet mop is squeezed out (Figures 4, 5 and 6).

[0023] The squeeze sieve 1 has a perforated squeeze sieve cup base 3 with a slightly upwardly arched central region, which is essentially circular. A surrounding sieve cup wall 5 rises upwards and outwards from the rounded edge 4 pressing against the sieve cup bottom 3 . The bottom 3 of the sieve cup and the wall 5 of the sieve cup form a sieve cup body 6, which gradually expands from bottom to top. The cross-section ( FIG. 2 ) of the sieve cup wall 5 provided with discontinuities such as slits 7 and possibly ribs 7 a is arched toward the inside of the sieve cup body 6 .

[0024] With the preferred embodiment described above, the sieve cup wall 5 rising upwards from the edge 4 of the sieve cup bottom 3 forms outwards a slope angle with the vertical S of less than 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com