FH36 steel plate for economical icebreaker and preparation method thereof

An icebreaker, economical technology, applied in the direction of metal rolling, etc., can solve the problems of not providing brittle fracture resistance, strain aging performance, lack of brittle fracture resistance, strain aging performance, lack of FH36 steel plate production technology, etc., to improve Effect of strain aging performance, improvement of brittle fracture resistance, and reduction of crack probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

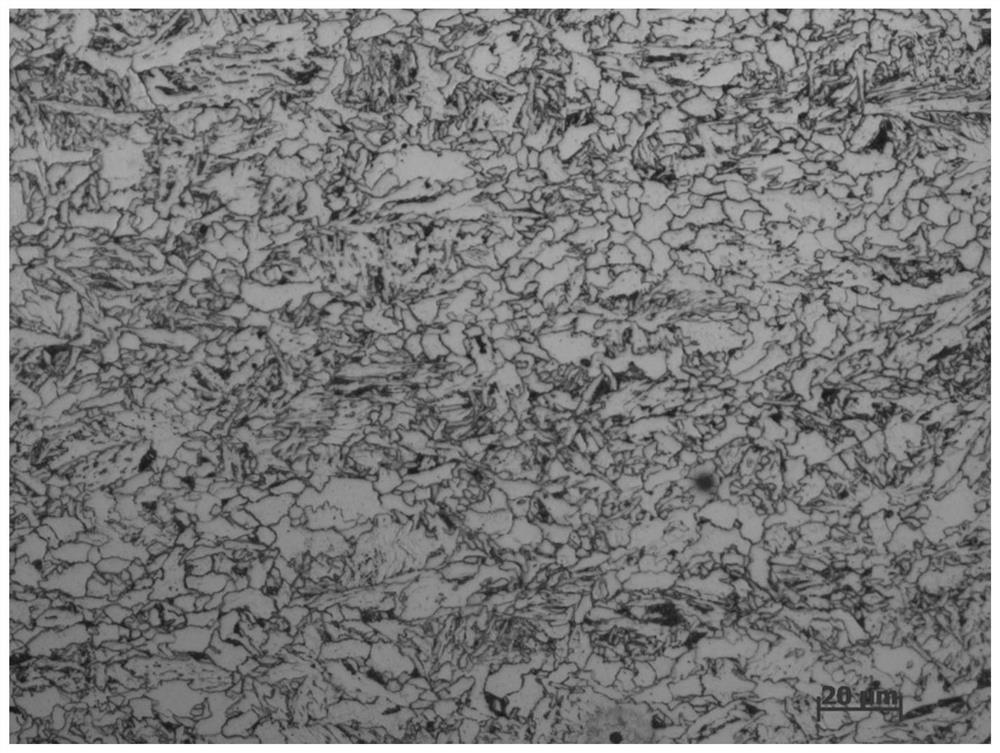

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below with reference to the embodiments, which are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

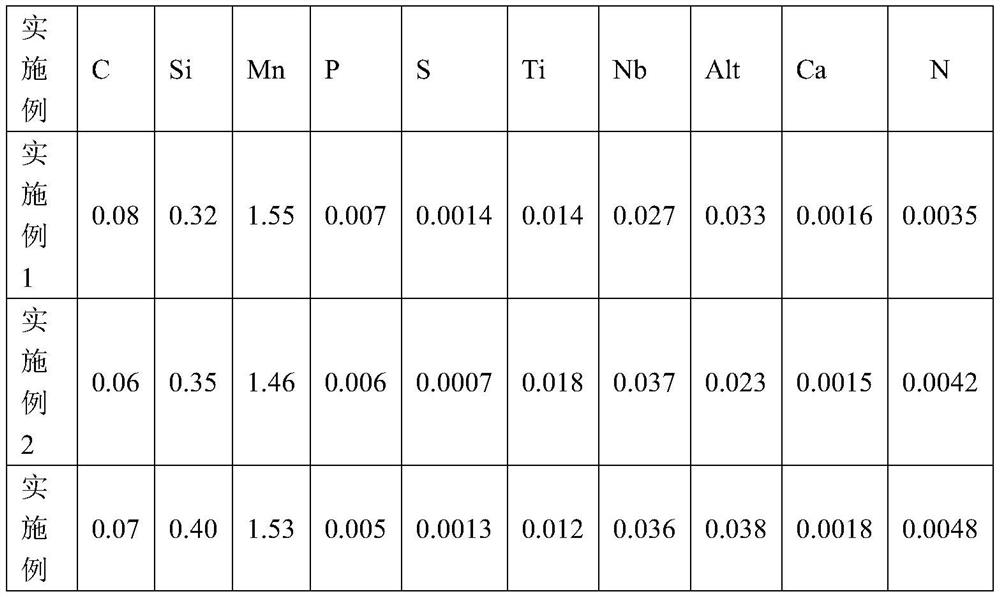

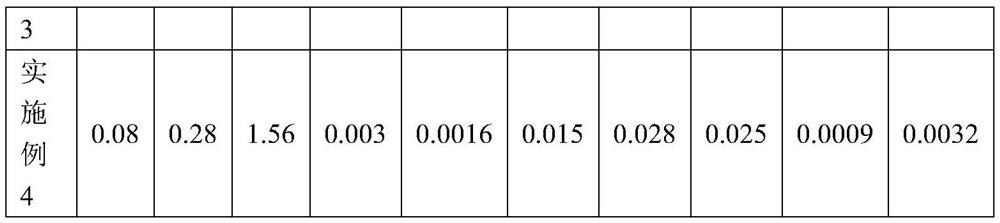

[0031] The chemical composition of the economical icebreaker FH36 steel plate corresponding to each embodiment is shown in Table 1. The data in the table is the mass percentage content of each element, and the remainder is Fe and inevitable impurity elements.

[0032] Table 1

[0033]

[0034]

[0035] The production process of the steel plate is as follows:

[0036] Smelting and continuous casting: select high-quality raw materials, use molten iron pretreatment, KR deep desulfurization, and the sulfur content is less than 0.0020%; converter tapping adopts premelting refining slag + active lime for slagging; converter end point C≤0.02%, the tapping process is carried out Argon and nitrogen are blown at the bottom for 15 to 20 minutes, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com