Eight-shaft linkage intelligent control equipment for high-manganese steel lining plate

A high manganese steel liner and intelligent control technology, applied in the coating process and coating of metal materials, can solve the problems of inconvenient movement, increase production, and reduce cladding effect, so as to improve cladding effect and heat dissipation Efficiency and the effect of shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

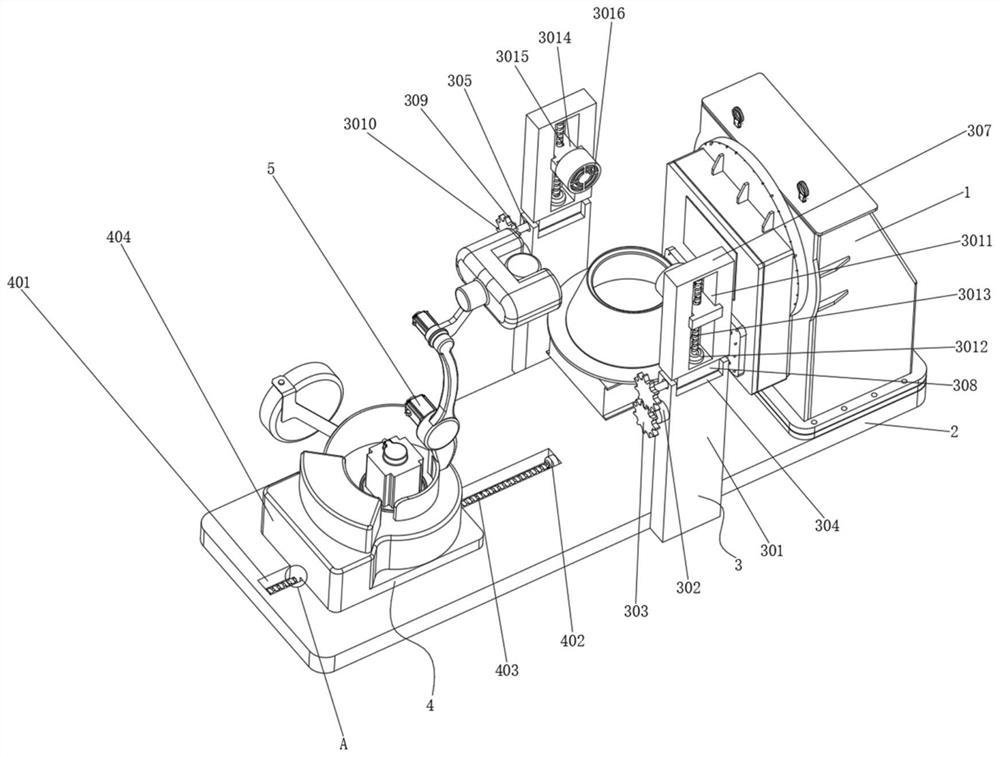

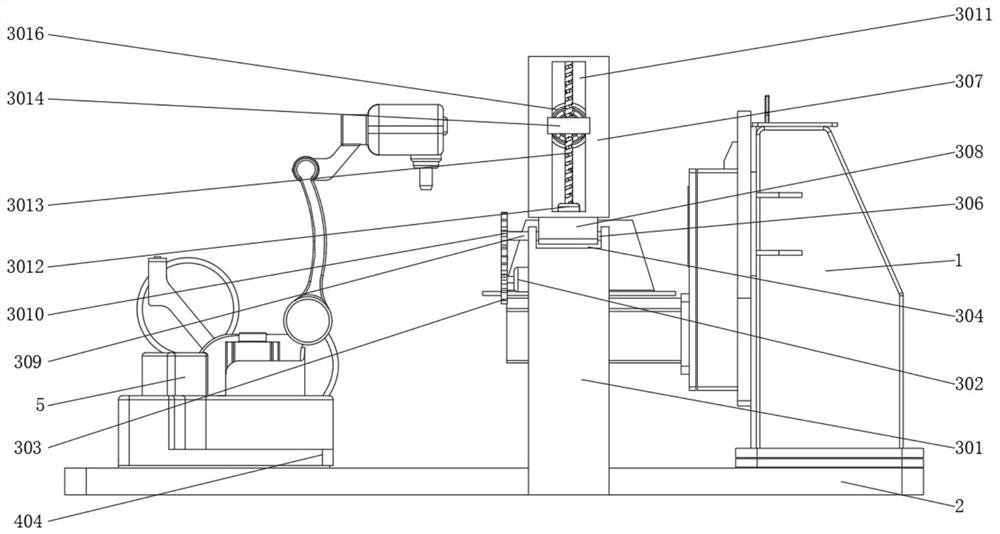

[0019] see image 3 , high manganese steel lining plate eight-axis linkage intelligent control equipment, including positioner main body 1, base 2, heat dissipation assembly 3 and moving assembly 4, base 2 is fixedly connected to the outer wall of the bottom end of positioner main body 1, and base 2 The heat dissipation assembly 3 is fixed on the outer walls of both sides, and the mobile assembly 4 is fixed on the top outer wall of the base 2; the cladding mechanism 5 is fixedly installed on the top outer wall of the base 404, and the high manganese steel liner can be cleaned by the cladding mechanism 5. Cladding, improving the cladding effect;

[0020] The cooling assembly 3 includes a supporting plate 301, a first motor 302, a driving gear 303, a rotating slot 304, a rotating hole 305, a rotating shaft 306, a turning plate 307, a rotating plate 308, a connecting rod 309, a driven gear 3010, and a first chute 3011, the second motor 3012, the first threaded rod 3013, the firs...

Embodiment 2

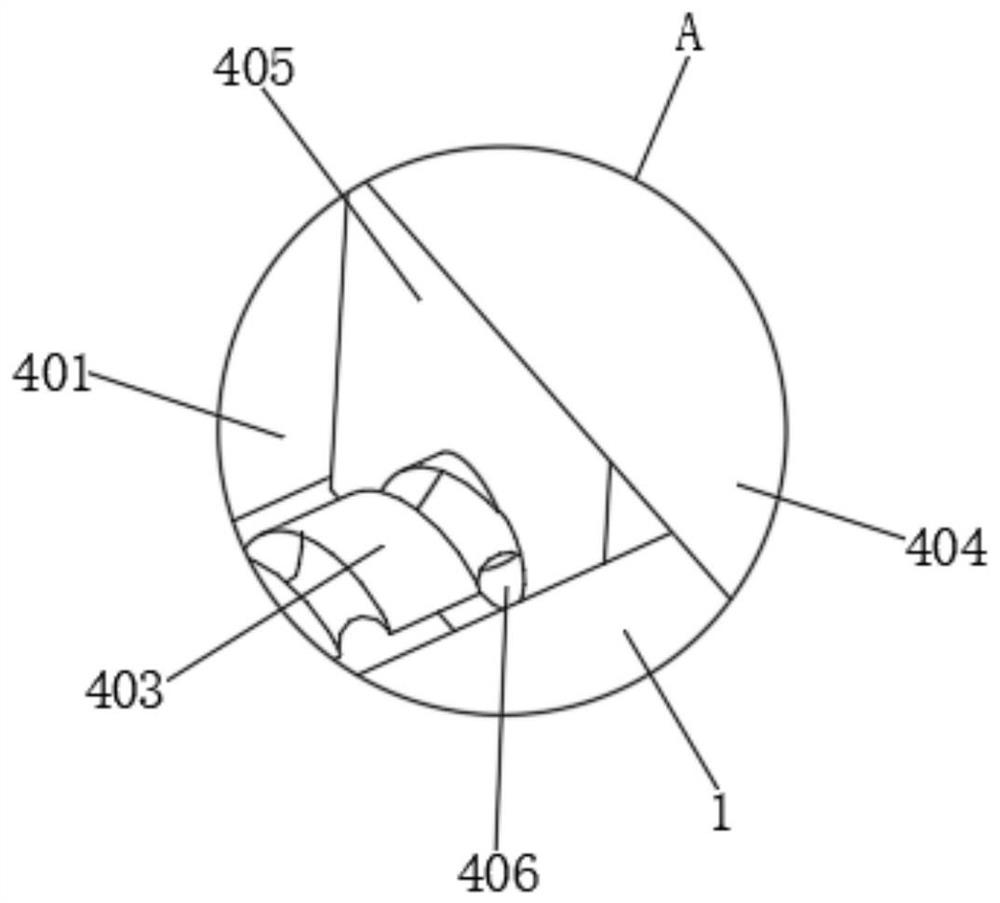

[0023] see Figure 1-2 , the moving assembly 4 includes a second chute 401, a third motor 402, a second threaded rod 403, a base 404, a second slider 405 and a second threaded hole 406, and the base 404 is installed on the top outer wall of the base 2, A second slider 405 is welded and fixed on the outer wall of the bottom end of the base 404, and a second chute 401 is provided on the top outer wall of the base 2 corresponding to the second slider 405, and a side inner wall of the second chute 401 is inlaid with a The third motor 402, the other side inner wall of the third motor 402 is rotatably connected with the second threaded rod 403, and one end of the output shaft of the third motor 402 is fixed on the outer wall of the second threaded rod 403, and the second slider 405 Corresponding to the second threaded rod 403, there is a second threaded hole 406 on one side of the inner wall; the third motor 402 is a servo motor, which makes the second threaded rod 403 rotate positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com