Safety protection device for tunnel blasting

A technology of safety protection device and tunnel, which is applied in the direction of safety device, dust prevention, fire prevention, etc. It can solve the problems of insufficient supporting strength of the roller, difficulty in pushing, and affecting the sight of the staff, so as to avoid the impact of dust on the line of sight and reduce the hard impact force , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

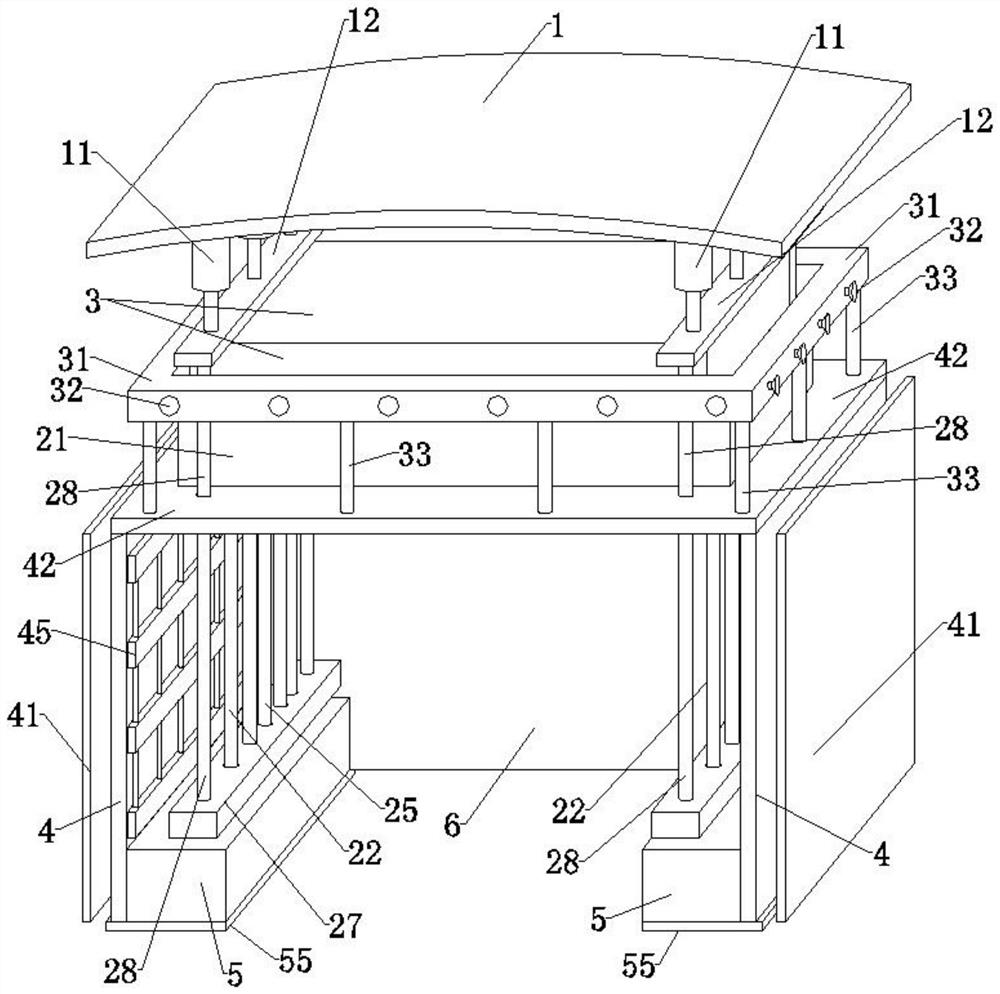

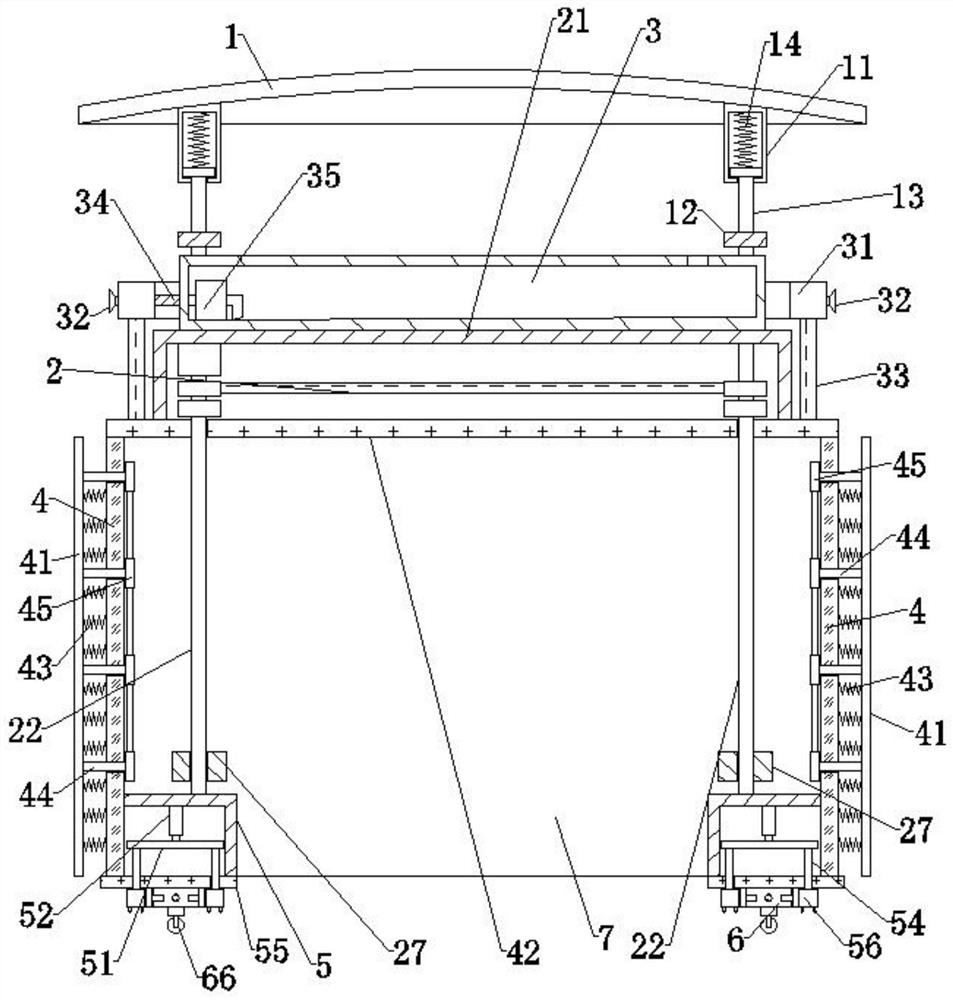

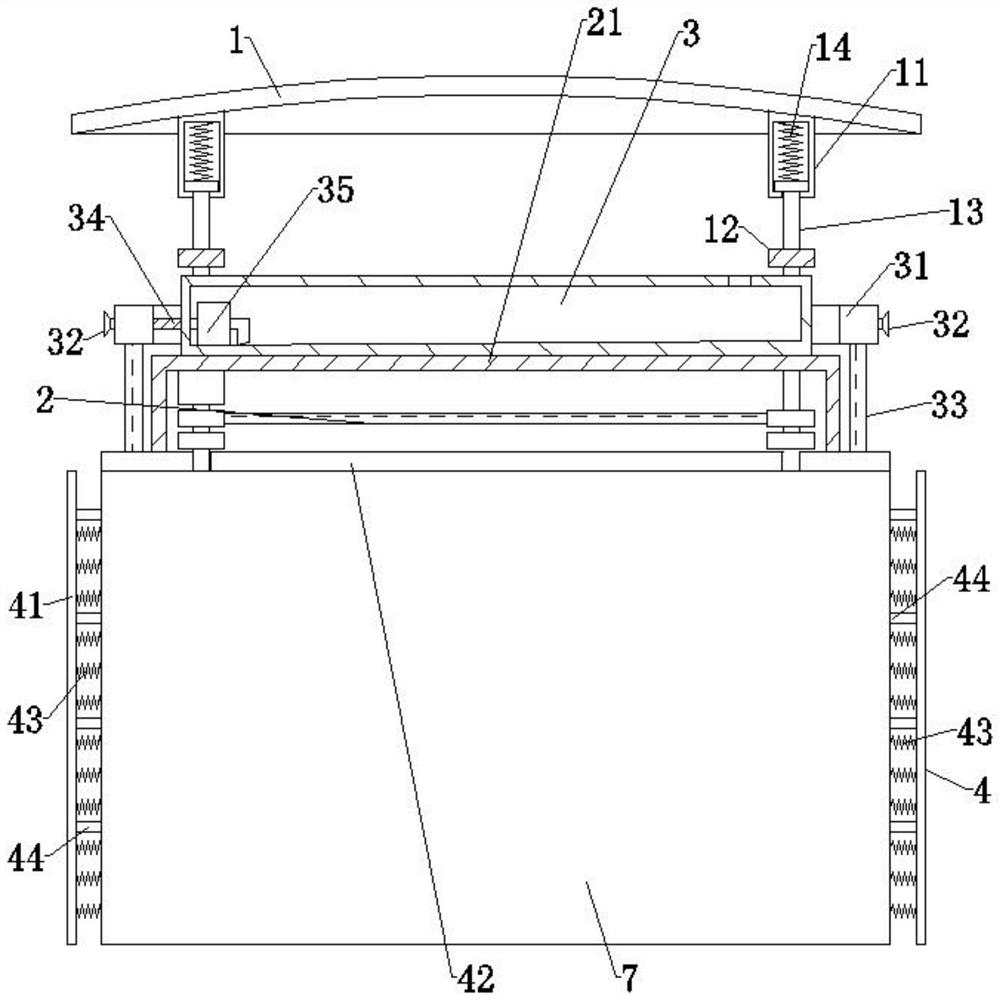

[0053] see Figures 1 to 11 As shown, the present invention provides a technical solution: a safety protection device for tunnel blasting, comprising:

[0054] An explosion point guard plate 7 and two side baffle plates 4 are mutually fixed and set as a vertical protective enclosure with three sides closed and one side open, and the two side baffle plates 4 are erected on the left and right sides of the explosion point guard plate 7, so The top of the explosion point guard plate 7 and the side baffle plate 4 is also horizontally fixed and equipped with a support top plate 42, and the support top plate 42 completely blocks the explosion point guard plate 7 and the side baffle plate 4 enclosure ranges;

[0055] The lifting mechanism 2 is stably installed on the support top plate 42, and the support shell 21 is set on the outside;

[0056] The water storage tank 3 is fixedly mounted on the top of the supporting shell 21, and a spray pipe 31 is surrounded on the outside. The inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com