Paper flaw detection system and method

A defect detection and paper technology, applied in the direction of optical defect/defect test, measuring device, material analysis through optical means, etc., can solve problems such as quality accidents, defect detection that cannot be realized by visual inspection, and missed detection of common defects, so as to avoid The effect of defect detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

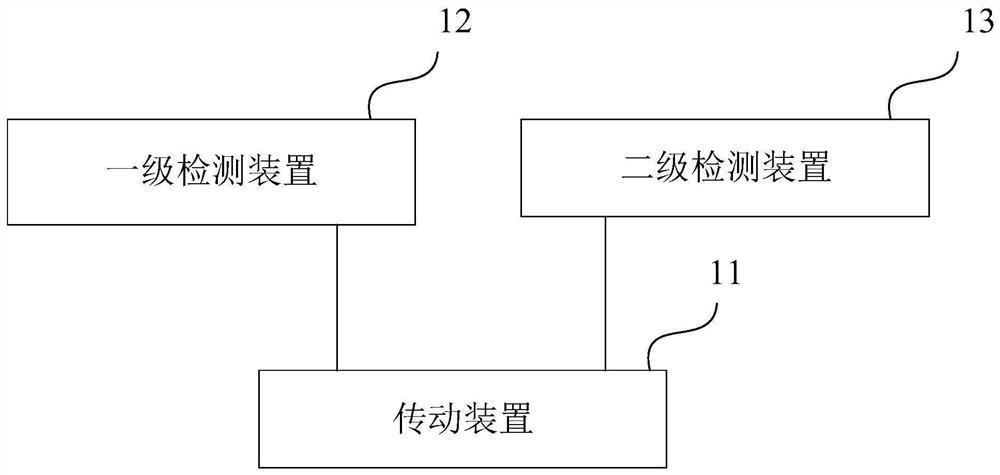

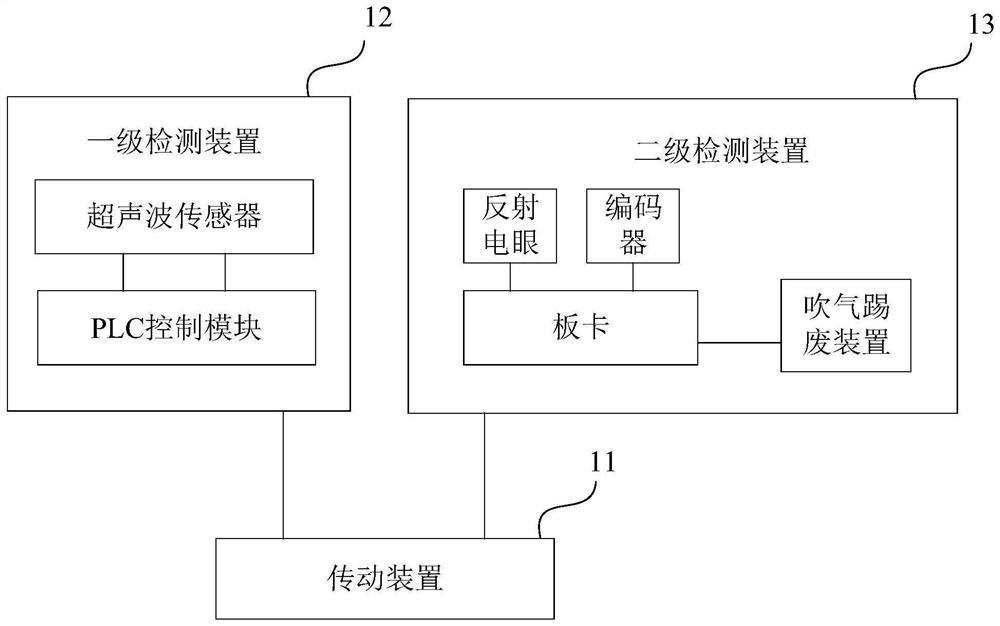

[0023] figure 1 It is a schematic structural diagram of a paper defect detection system provided in Embodiment 1 of the present invention, and this embodiment is applicable to the detection of paper defects.

[0024] Such as figure 1 As shown, a paper defect detection system provided by Embodiment 1 of the present invention includes: a primary detection device 12 and a secondary detection device 13 fixed on a transmission device 11, and the transmission device 11 is used to transport the paper to be tested.

[0025] In this embodiment, the transmission device may be a device with a transmission function such as a conveyor belt. The transmission device transmits the paper to be tested through the first-level detection device and the second-level detection device fixed on the transmission device in turn. A device for detecting defective sheets including non-perfectly overlapping double sheets in the sheet to be tested.

[0026] The transmission device can be driven by a motor...

Embodiment 2

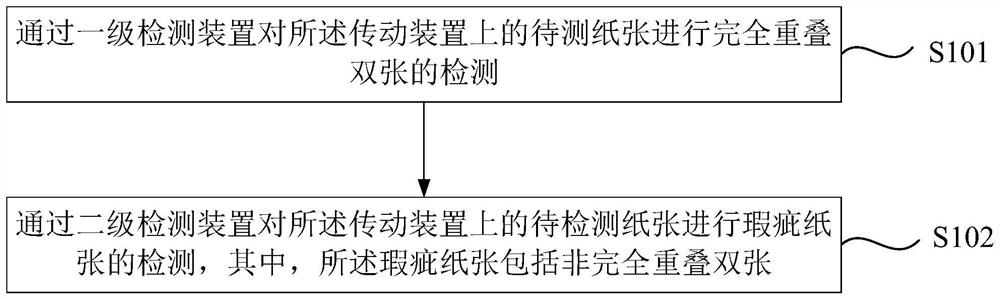

[0098] image 3 It is a flow chart of a paper defect detection method provided in Embodiment 2 of the present invention. This embodiment is applicable to paper defect detection, and the method can be executed by the paper defect detection system provided in the above embodiment.

[0099] like image 3 As shown, the method specifically includes the following steps:

[0100] S101. Using a primary detection device to detect completely overlapping double sheets of the paper to be tested on the transmission device.

[0101]It should be noted that the transmission device is a device for transmitting the paper to be tested for paper detection, and the primary detection device is fixed on the transmission device to detect completely overlapping double sheets of the paper to be tested. An ultrasonic sensor and a first control module are installed in the primary detection device, and the ultrasonic sensor is connected to the first control module through a single-sheet detection signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com