Automatic overturning type frame alkali washing jig

A technology of automatic flipping and frame, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effect of saving man-hours, neat appearance and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

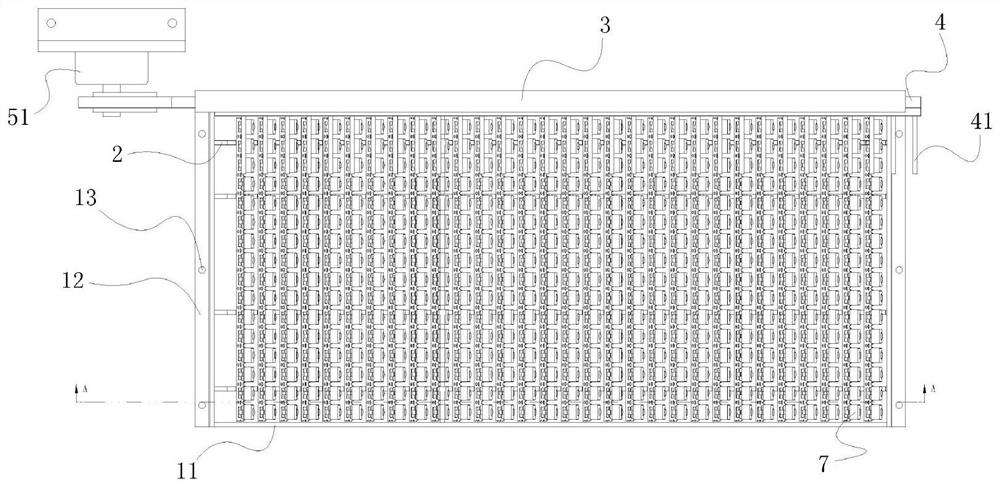

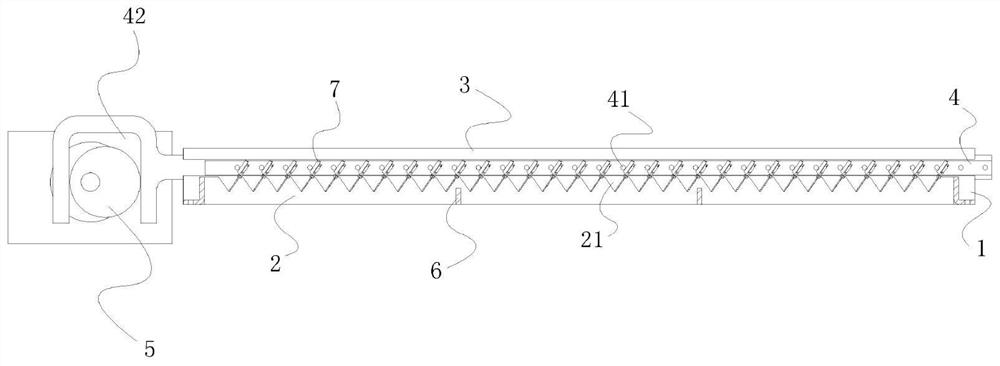

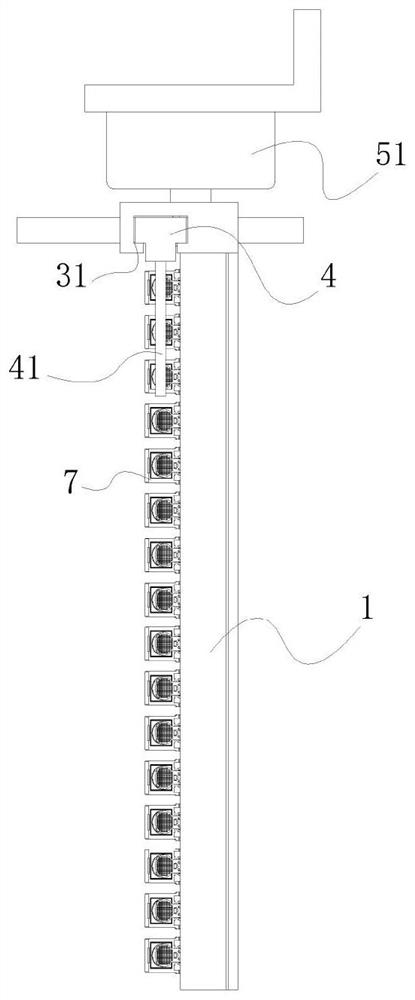

[0037] This embodiment provides an automatic flip-type frame alkali cleaning treatment tool, which includes a closed-loop frame, and a positioning straight plate 2 is arranged inside the frame, and several V-shaped positioning grooves 21 are evenly arranged on the upper end surface of the positioning straight plate 2, and one side of the frame is provided with There is a guide rail 3, and the guide rail 3 is provided with a T-shaped guide groove 31 with an opening facing the positioning straight plate 2. The T-shaped guide groove 31 is parallel to the positioning straight plate 2, and the T-shaped guide groove 31 is provided with a slidingly fitted T-shaped slide bar 4, T The outer surface of the shape slide bar 4 is horizontally provided with a material shifting rod 41 corresponding to the V-shaped positioning groove 21, the material shifting rod 41 is corresponding to the neutral position of the V-shaped positioning groove 21, and the horizontal height of the material shifting...

Embodiment 2

[0040] This embodiment provides an automatic flip-type frame alkali cleaning treatment tool, which includes a closed-loop frame, and a positioning straight plate 2 is arranged inside the frame, and several V-shaped positioning grooves 21 are evenly arranged on the upper end surface of the positioning straight plate 2, and one side of the frame is provided with There is a guide rail 3, and the guide rail 3 is provided with a T-shaped guide groove 31 with an opening facing the positioning straight plate 2. The T-shaped guide groove 31 is parallel to the positioning straight plate 2, and the T-shaped guide groove 31 is provided with a slidingly fitted T-shaped slide bar 4, T The outer surface of the shape slide bar 4 is horizontally provided with a material shifting rod 41 corresponding to the V-shaped positioning groove 21, the material shifting rod 41 is corresponding to the neutral position of the V-shaped positioning groove 21, and the horizontal height of the material shifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com