Turbine housing having low-stress connecting flange and exhaust turbine having such turbine housing

A technology of turbine casing and exhaust turbine, which is applied to machines/engines, gas turbine devices, mechanical equipment, etc. Effects of extended service life, low transient thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

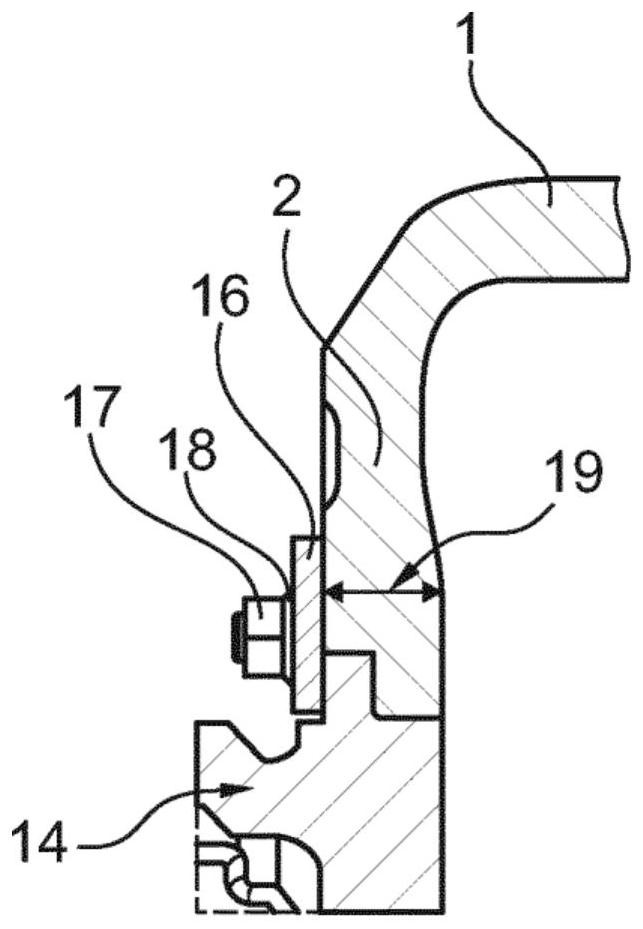

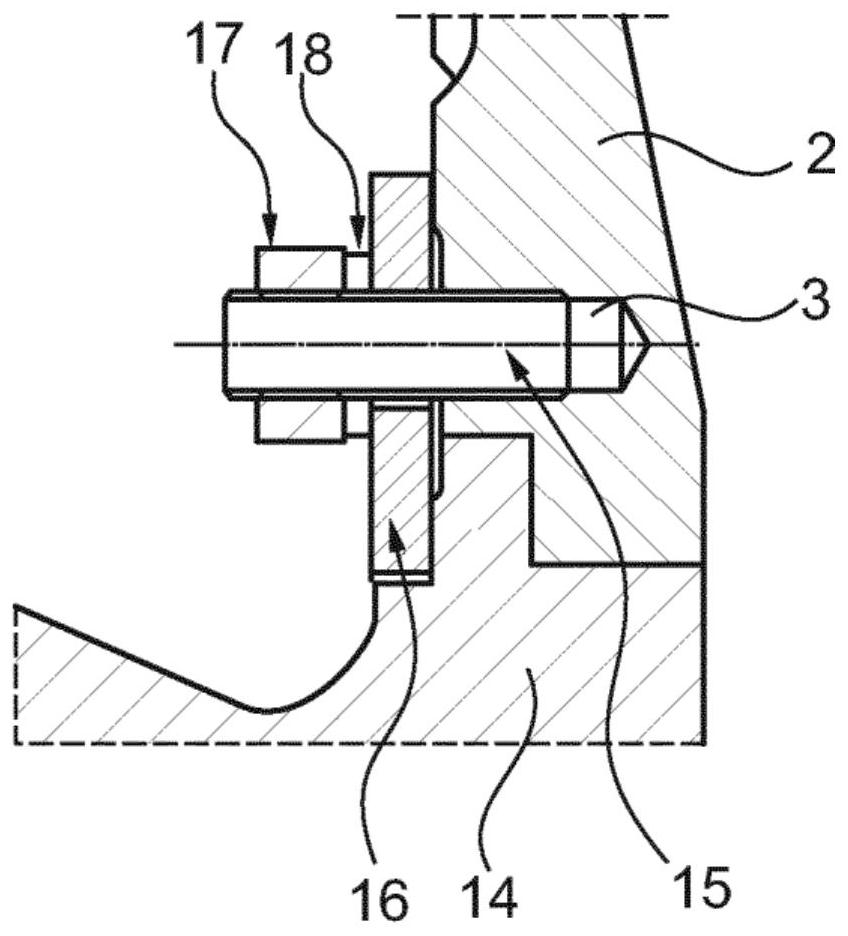

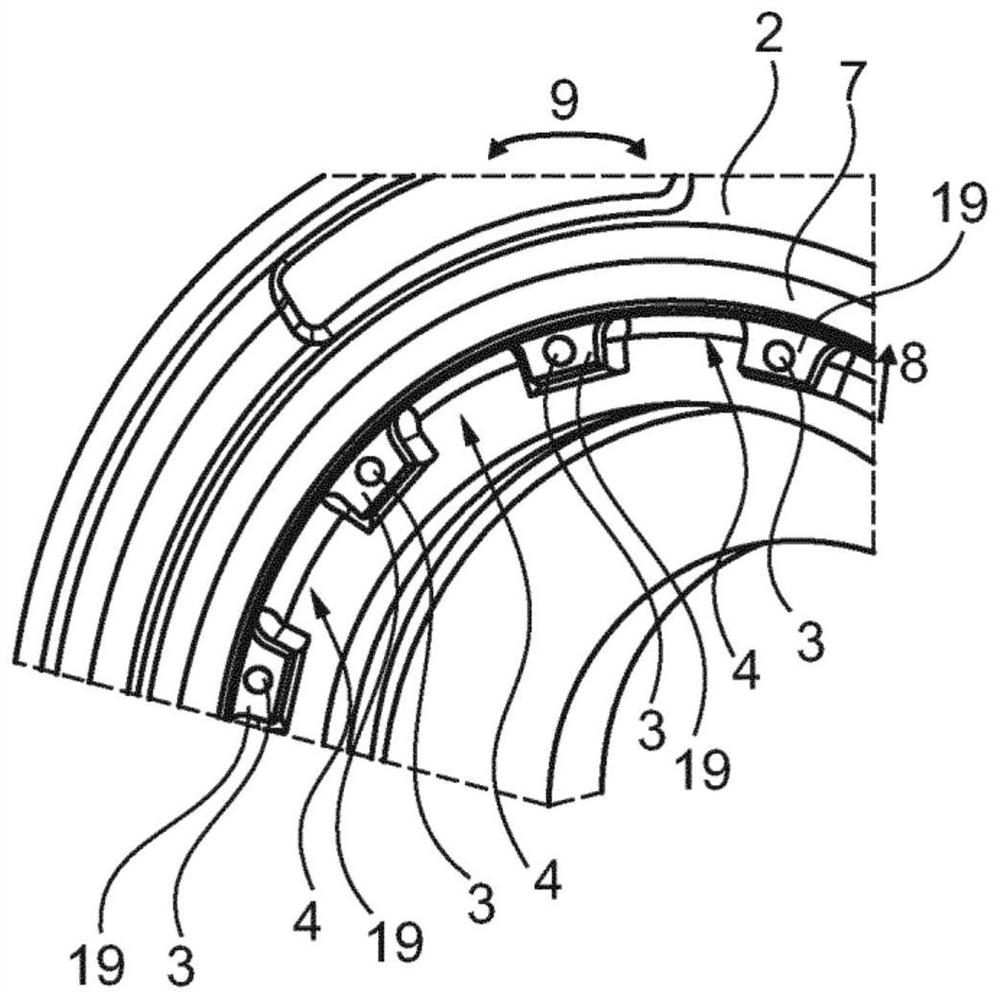

[0040] image 3 A sketch for illustrating a turbine housing according to the invention is shown, where in image 3Only a partial area of the turbine housing is shown in . The turbine housing has a connecting flange 2 arranged coaxially to the longitudinal center axis of the turbine housing, which is equipped with a clamping edge 7 . In the clamping edge 7 there is provided a connecting web 19 extending inwardly in the radial direction 8 , into which the housing connecting hole 3 is introduced. The mentioned connection webs 19 and the housing connection openings 3 inserted therein are spaced apart from one another in the circumferential direction 9 of the turbine housing. The connection lugs and the housing connection openings are arranged along one or more circles in the circumferential direction 9 in the connection flange. Between every two housing connection openings 3 spaced apart from one another in the circumferential direction 9 , a material recess 4 which is open r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com