Roller type quilt rolling machine for agricultural greenhouse

A quilt rolling machine and roller type technology used in the field of agricultural greenhouses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

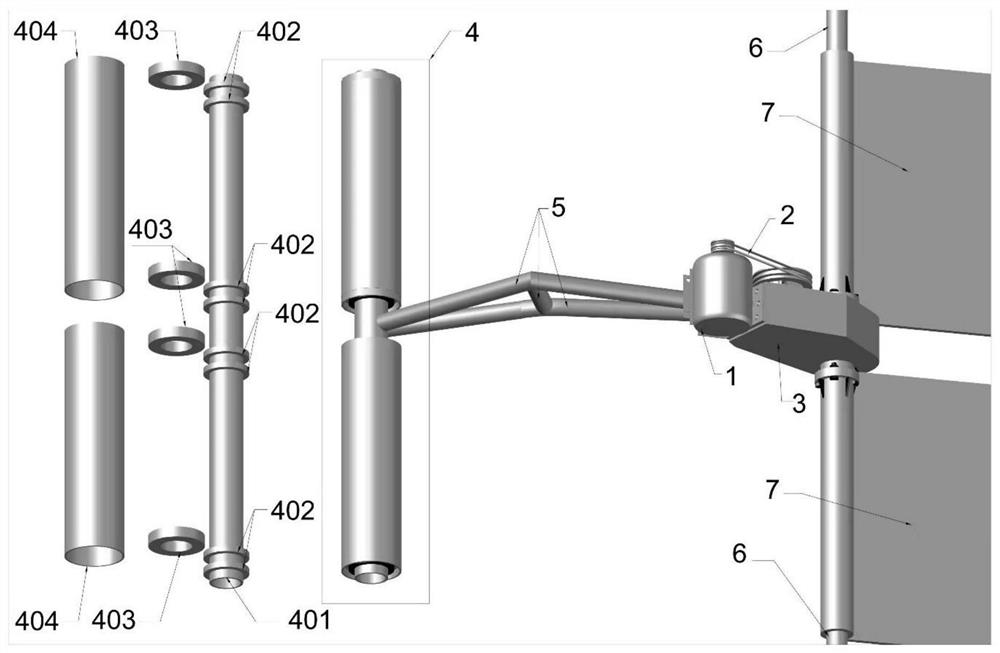

[0036] Such as figure 1 As shown, a roll-type quilt rolling machine for agricultural greenhouses, including a motor 1, a transmission part 2, a reducer 3, a support roller set 4, a support connector 5, a roll quilt rod 6 and a quilt 7, does not contain roll cotton The quilt rod 6 and the quilt 7 are the roll quilt host; the motor 1 drives the reducer 3 to work through the transmission part 2, and the rear end of the reducer 3 is connected to the support roller set 4 through the connecting plate and the support connector 5, and the reducer 3 The inside of the front end intersects with the roll quilt rod 6, and the 7 rolls of quilt are placed on the roll quilt rod 6; the motor 1 drives the reducer 3 through the transmission part 2, and the reducer 3 drives the roll quilt rod 6 through the intersecting connection part The rotation of finishing cotton-wadded quilt 7 is put.

[0037] The length of the rolled quilt rod 6 in this embodiment is 60-80 meters, and the support roller se...

Embodiment 2

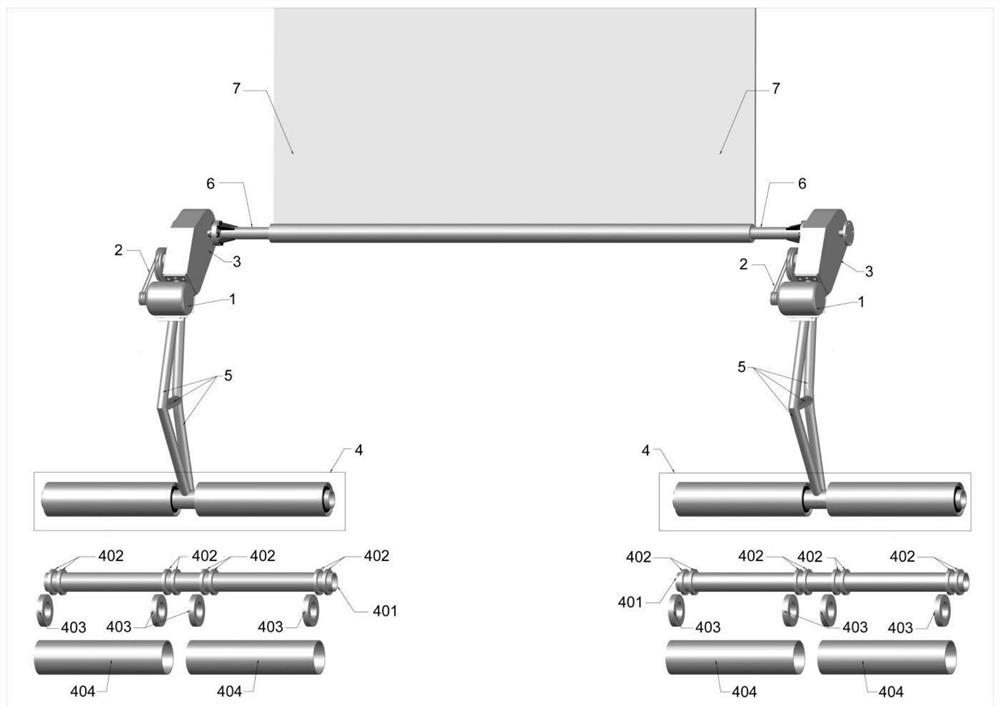

[0044] Such as figure 2 As shown, a roll-type quilt rolling machine for agricultural greenhouses, including a motor 1, a transmission part 2, a reducer 3, a support roller set 4, a support connector 5, a roll quilt rod 6 and a quilt 7, does not contain roll cotton The quilt rod 6 and the quilt 7 are the roll quilt host; the motor 1 drives the reducer 3 to work through the transmission part 2, and the rear end of the reducer 3 is connected to the support roller set 4 through the connecting plate and the support connector 5, and the reducer 3 The inside of the front end intersects with the roll quilt rod 6, and the 7 rolls of quilt are placed on the roll quilt rod 6; the motor 1 drives the reducer 3 through the transmission part 2, and the reducer 3 drives the roll quilt rod 6 through the intersecting connection part The rotation of finishing cotton-wadded quilt 7 is put.

[0045] The length of the rolled quilt rod 6 in this embodiment is 110-130 meters, and the support roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com