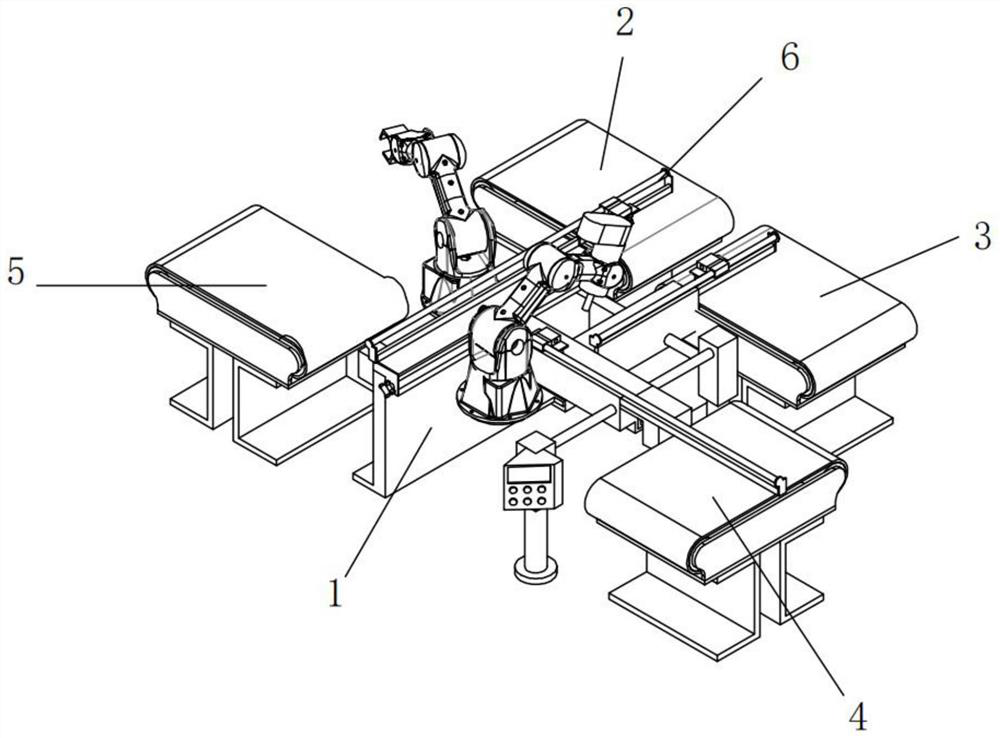

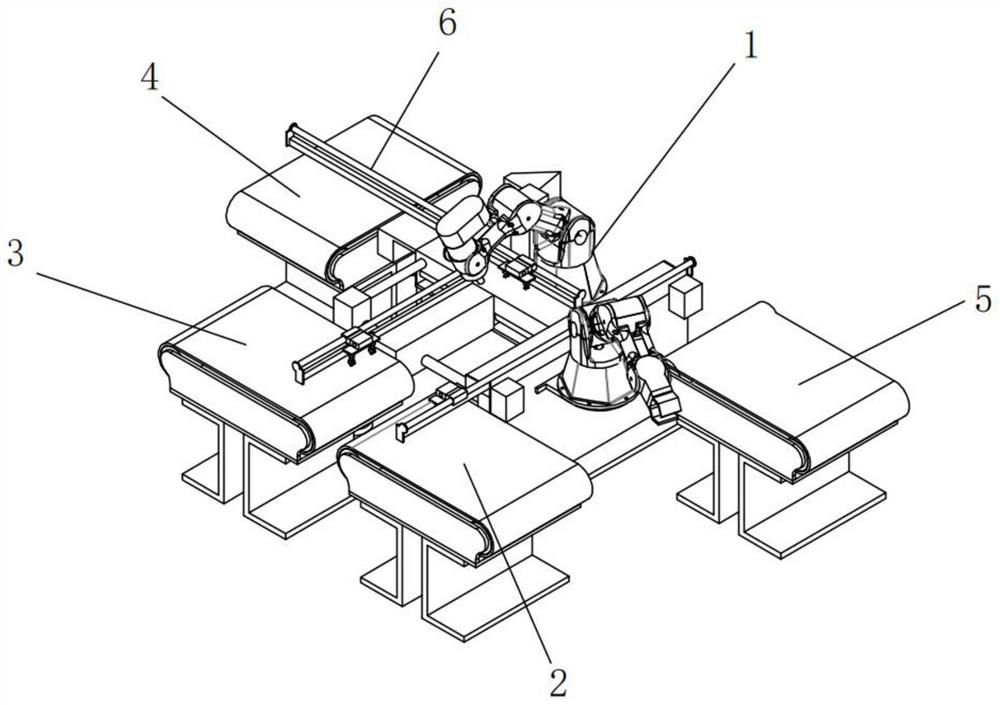

Carbon fiber umbrella rib assembling device and assembling method thereof

An assembly device and assembly method technology, applied in the direction of walking sticks, etc., can solve the problems of cumbersome assembly positioning means, troublesome assembly position adjustment, and affecting assembly efficiency, etc., and achieve the effects of fewer stations, fast assembly positioning, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

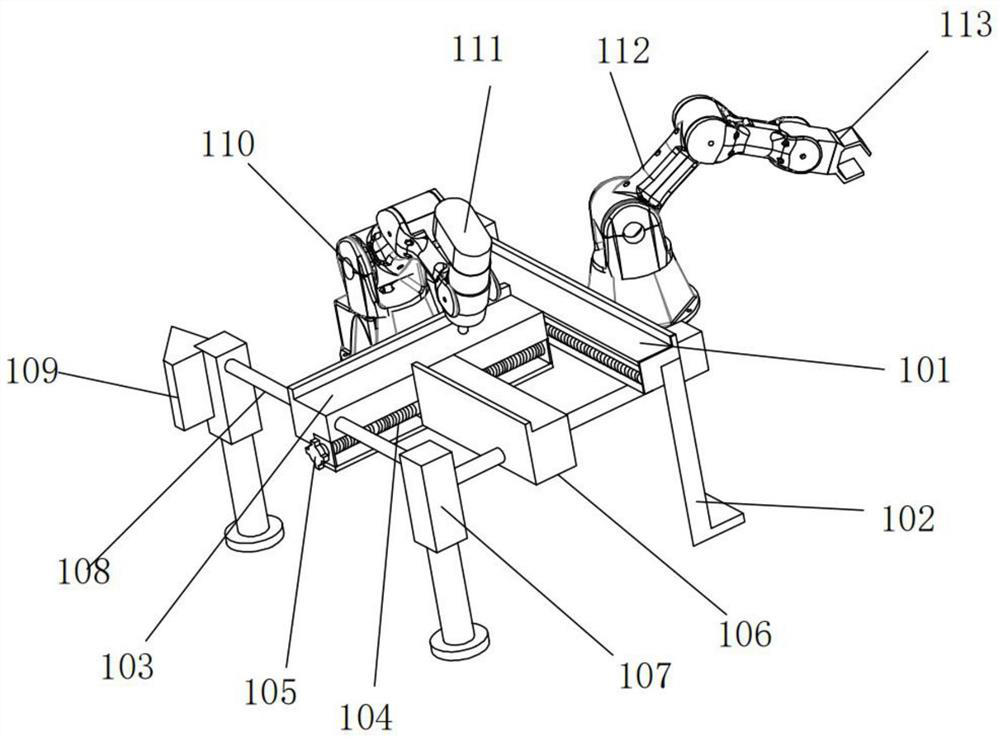

Embodiment

[0037] The umbrella frame manufactured by this equipment is mainly divided into three parts, one is the stress rod connected with the umbrella surface, the other is the support rod fixed at the bottom of the support rod by rotation, and the push rod used to push the support rod to rotate. Wherein the force rod is connected with the umbrella top, the support rod is connected with the support block under the umbrella top, and the push rod is connected with the slider in the umbrella, as Figure 5 Shown is the umbrella frame assembly form that the equipment is mainly aimed at. Because the carbon fiber umbrella frame is stronger, it is different from the multi-support design of other umbrella frames in the production process. The structure of the carbon fiber umbrella frame is relatively simple and the strength is also high. , this equipment is mainly for the assembly of carbon fiber ribs with different assembly sizes, only for the assembly of a single rib and does not consider the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com