Small automobile instrument dial plate mounting device

A technology for installation devices and small cars, which is applied in the direction of workpiece clamping devices, metal processing equipment, metal processing, etc., can solve the problems of waste of manpower and time, low efficiency, etc., to save working hours, reduce workload and strength, and improve qualification rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

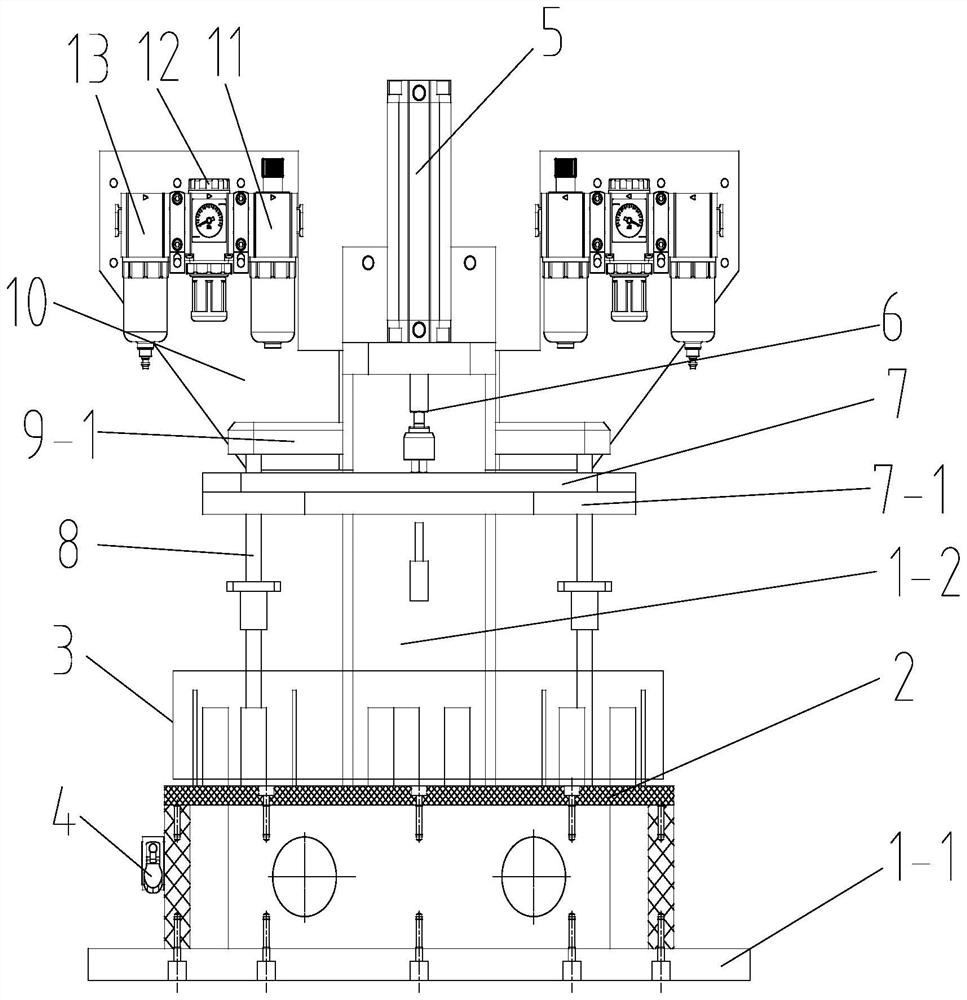

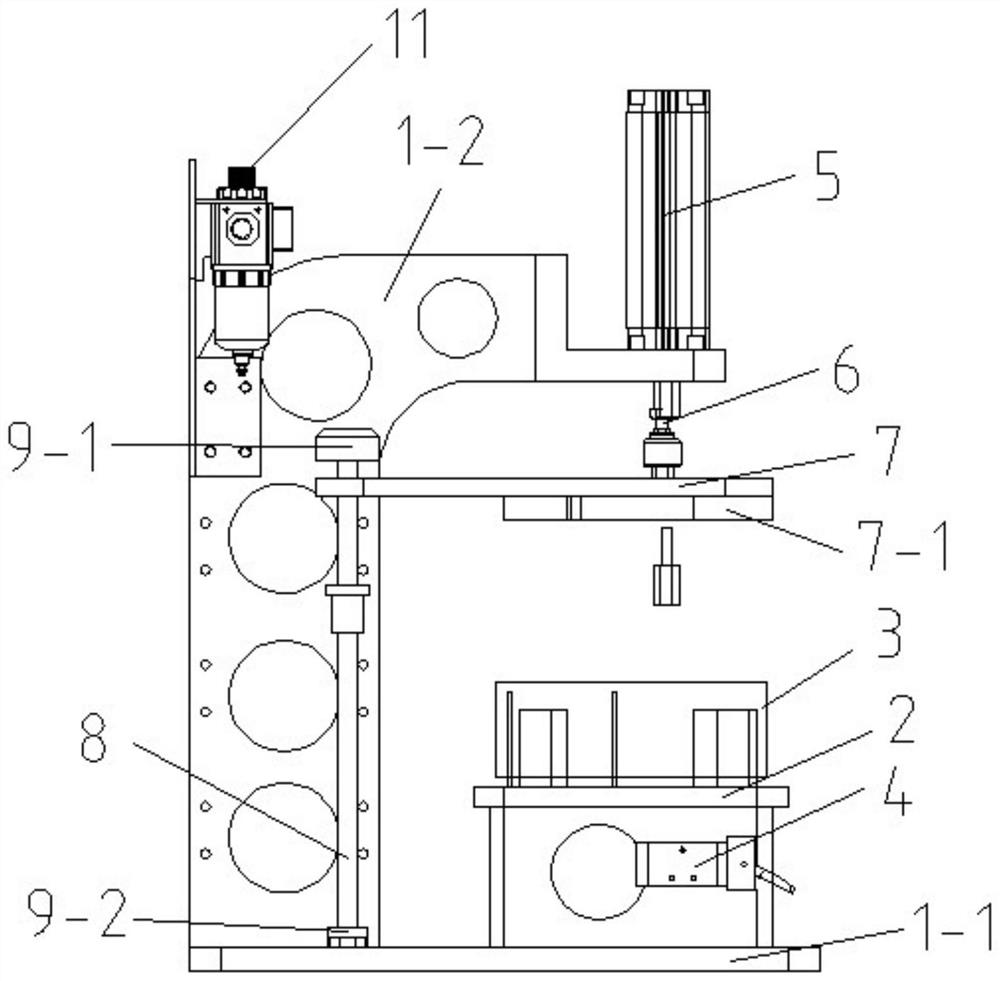

[0010] Specific implementation mode one: combine Figure 1-Figure 2 This embodiment is described. A small-sized automobile instrument panel installation device described in this embodiment includes a frame, an instrument fixing component, a dial pressing component and a lifting component. The frame is used to install various components and supports the overall structure. The frame includes a base plate 1-1 and a support frame 1-2, the support frame 1-2 includes a vertical support frame and a horizontal support frame, and one end of the vertical support frame is fixedly connected to the center position on one side of the upper surface of the base plate 1-1, and the vertical support frame The other end of the straight support frame is fixedly connected to one end of the horizontal support frame, and the horizontal support frame and the vertical support frame are vertically arranged, the vertical support frame and the horizontal support frame are integrated, and the other end of t...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination Figure 1-Figure 2 Describe this embodiment mode, a kind of small-sized automobile dashboard installation device described in this embodiment mode, it also comprises two installation boards 10, and two installation boards 10 are respectively fixedly installed in the middle and upper part of the left and right sides of the vertical support frame, two Mounting plates 10 are arranged symmetrically about the central axis of the vertical support frame, and each mounting plate 10 is all positioned at the rear of each group of connecting frames, the rear surfaces of the two mounting plates 10, the rear surface of the vertical support frame and the base plate 1-1 The rear surfaces are in the same plane, and the others are the same as in Embodiment 1.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination Figure 1-Figure 2 Illustrate this embodiment, a kind of small-sized automobile dashboard installation device described in this embodiment, it also comprises auxiliary assembly, and auxiliary assembly is installed on each installation plate 10, and auxiliary assembly includes air filter 11, pressure reducing valve 12 and oil Mist separator 13, air filter 11 is used to filter dust and impurities in the air; pressure reducing valve 12 is used to adjust air pressure, air pressure range: 0.3MPa~0.5MPa; oil mist separator 13 is used to filter dust and impurities in the air Oily. An air filter 11 , a pressure reducing valve 12 and an oil mist separator 13 are arranged in sequence on the front surface of each mounting plate 10 . Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com