Unpowered vacuum chuck with automatic centering function

A technology of automatic centering and vacuum suction cups, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of buffer collision between objects and supports, poor manual adjustment accuracy, and poor stability, etc. Accuracy, stable operation, and ingenious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

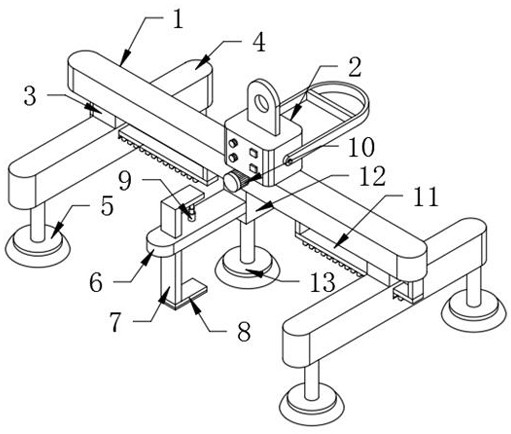

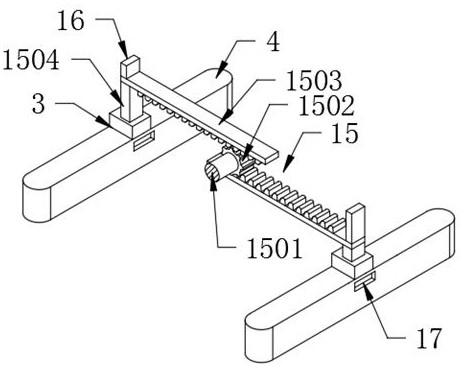

[0027] Such as figure 1 and figure 2 As shown, the present invention proposes a non-powered vacuum suction cup with automatic centering function, including a connecting rod 1 and a control box 2 connected to the upper end of the connecting rod 1, and the middle part of the lower end of the connecting rod 1 is connected with a suction cup 2 through a mounting base plate 12. 13. The inside of the connecting rod 1 is provided with a transmission adjustment mechanism 15. The transmission adjustment mechanism 15 includes two connecting rods 1504 slidingly connected to the lower surface of the connecting rod 1. The lower end of the connecting rods 1504 is connected to the moving rod 4 through the connecting block 3; The inside of the moving bar 4 is provided with a distance-adjusting mechanism 11, and the distance-adjusting mechanism 11 includes two guide blocks 1105 that are slidably connected to the lower surface of the moving bar 4, and the lower ends of the two guide blocks 110...

Embodiment 2

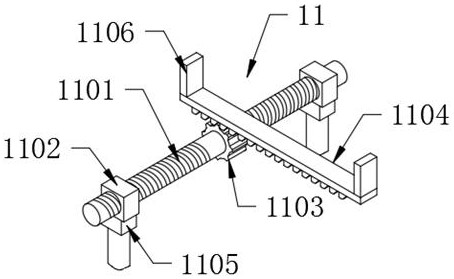

[0030] Such as figure 1 and image 3 As shown, the present invention proposes a non-powered vacuum chuck with automatic centering function. Compared with Embodiment 1, this embodiment also includes: the distance adjustment mechanism 11 includes a bidirectional adjustment screw 1101 that is rotatably connected to the moving rod 4 , the outer thread sleeve of the two-way adjusting screw 1101 is provided with two screw blocks 1102, and the two screw blocks 1102 are respectively fixedly connected with the upper ends of the two guide blocks 1105; The lower end is connected to a rack a1104 through a pair of fixed connecting plates 1106, and the rack a1104 is meshed with the corresponding transmission gear a1103 for transmission; the side surface of the moving rod 4 is provided with a rectangular slot 17, and the rack a1104 runs through the corresponding rectangular slot. Through slot 17, when the two moving rods 4 are close to each other, the two transmission gears a1103 are respec...

Embodiment 3

[0032] Such as Figure 1-3As shown, the present invention proposes a non-powered vacuum chuck with automatic centering function. This embodiment includes: a connecting rod 1 and a control box 2 connected to the upper end of the connecting rod 1. The middle part of the lower end of the connecting rod 1 passes through the installation base plate 12 The suction cup 2 13 is connected, and the inside of the connecting rod 1 is provided with a transmission adjustment mechanism 15. The transmission adjustment mechanism 15 includes two connecting rods 1504 that are slidably connected to the lower surface of the connecting rod 1. The lower end of the connecting rod 1504 is connected to a Moving bar 4; The inside of moving bar 4 is provided with distance-adjusting mechanism 11, and distance-adjusting mechanism 11 comprises two guide blocks 1105 that are slidably connected to the lower surface of moving bar 4, and the lower ends of two guide blocks 1105 are all provided with suction cups-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com