Titanium plating device and titanium plating method for stainless steel band

A technology for stainless steel strips and titanium plating, applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of non-recycling, waste of energy, low convenience of using titanium plating equipment, etc., to improve the use of The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

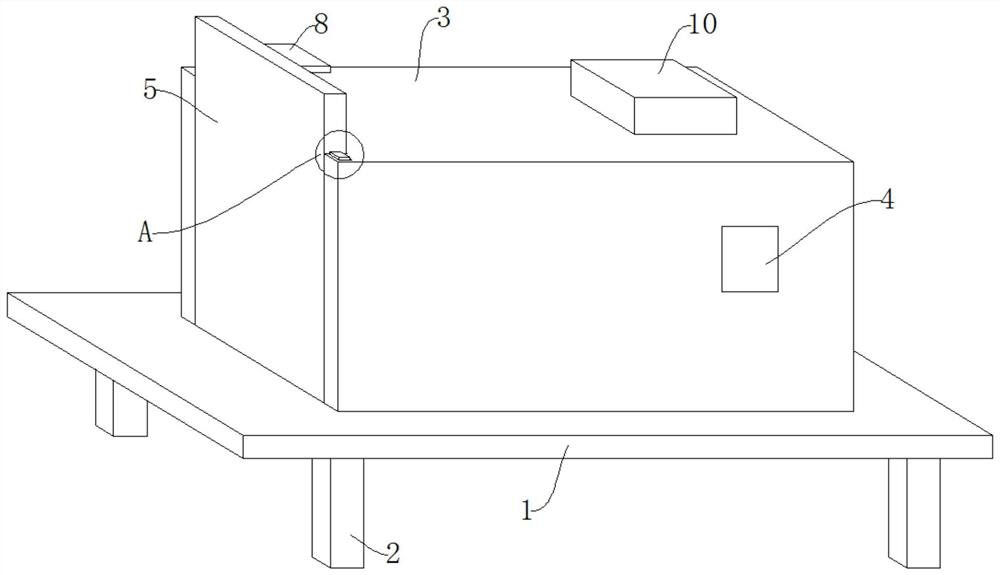

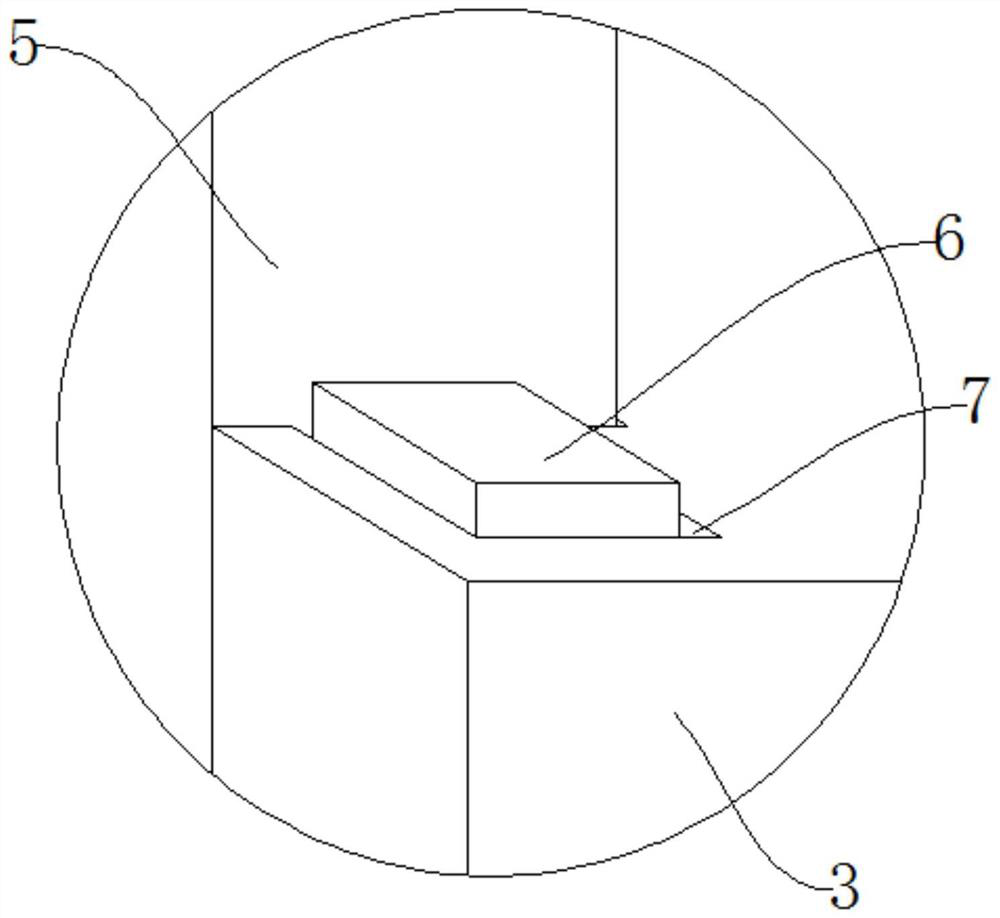

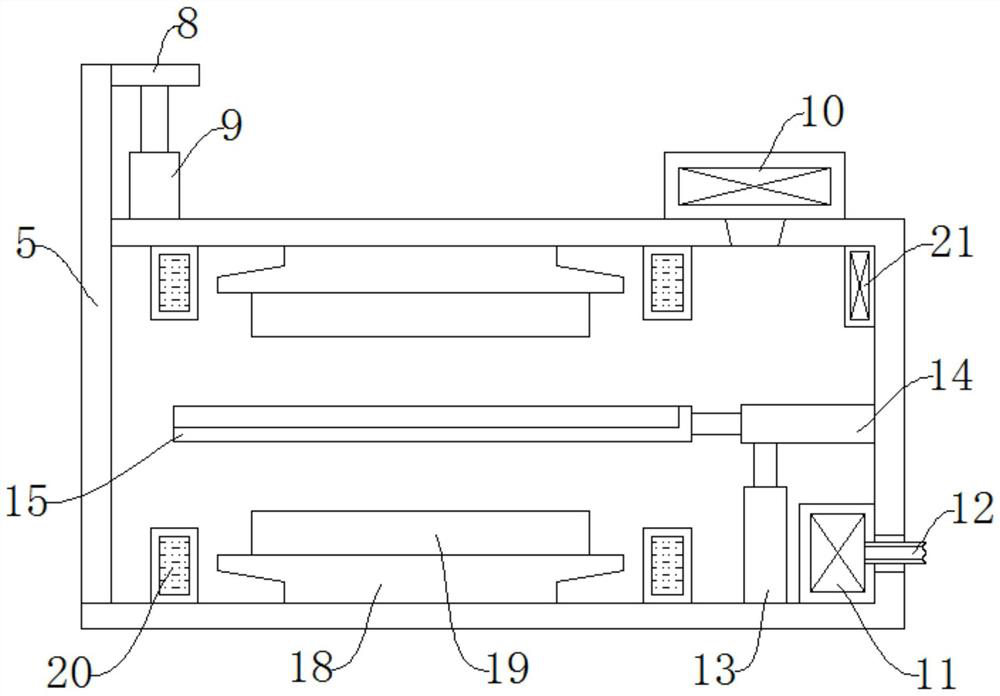

[0036] Such as Figure 1-Figure 5 As shown, a titanium plating device for a stainless steel strip includes a workbench 1, a titanium plating box 3 and a heat exchanger 11. The four corners of the lower end of the workbench 1 are equipped with pillars 2, and the middle part of the upper end of the workbench 1 is installed with The titanium-coated box 3 has an operation panel 4 installed on one side wall of the titanium-coated box 3, and a box door 5 is installed on the other side wall of the titanium-coated box 3, and the side walls at both ends of the box door 5 Sliders 6 are all provided, and a chute 7 is provided at the connection between the titanium-coated box 3 and the slider 6, and a connecting plate 8 is installed on the side wall of the door 5, and the lower end of the connecting plate 8 is installed There is an electric push rod 9, a vacuum pump 10 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com