Three-layer bearing

A technology for bearings and inner rings of bearings, applied to ball bearings, bearing components, shafts and bearings, etc., can solve the problems of limited number of balls, limited ability to reduce friction, and small bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

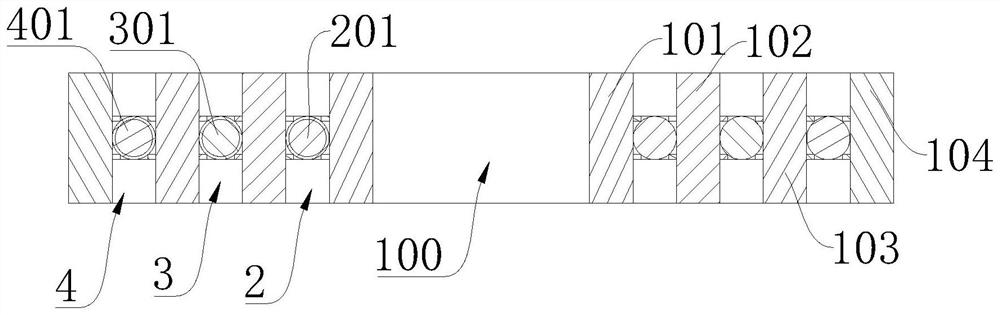

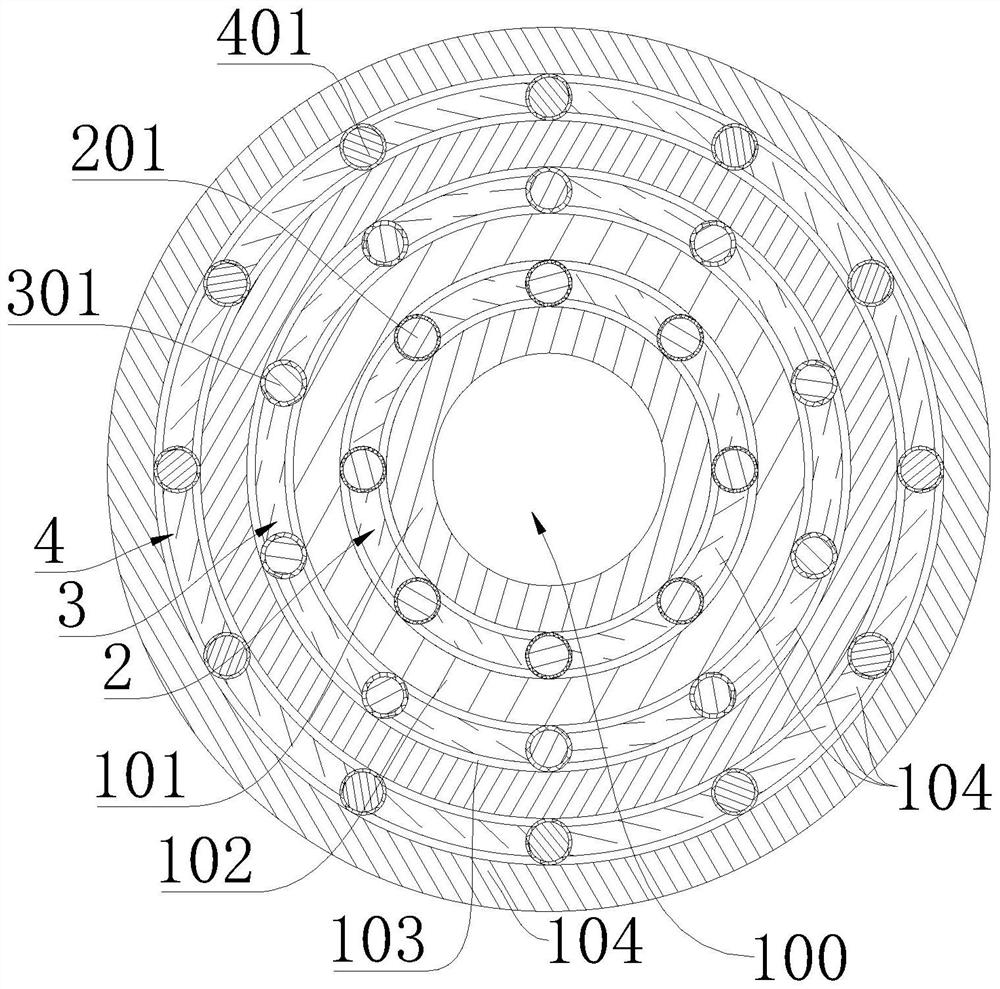

[0043] Such as figure 1 , 2 . Layer 2, the above-mentioned second rolling layer 3 and the above-mentioned third rolling layer 4 are all equipped with cages, and the above-mentioned matching layer 100, the above-mentioned first rolling layer 2, the above-mentioned second rolling layer 3 and the above-mentioned third rolling layer 4 are coaxial with each other , the above-mentioned first rolling layer 2 , the above-mentioned second rolling layer 3 and the above-mentioned third rolling layer 4 are arranged in sequence.

[0044] In this embodiment, it includes a matching layer 100, a first rolling layer 2, a second rolling layer 3 and a third rolling layer 4, and the matching layer 100 can be connected with a shaft; the above-mentioned first rolling layer 2, the above-mentioned second rolling layer 3 and the above-mentioned third rolling layer 4 are all equipped with cages, and the first rolling layer 2, the second rolling layer 3 and the third rolling layer 4 all include commo...

Embodiment 2

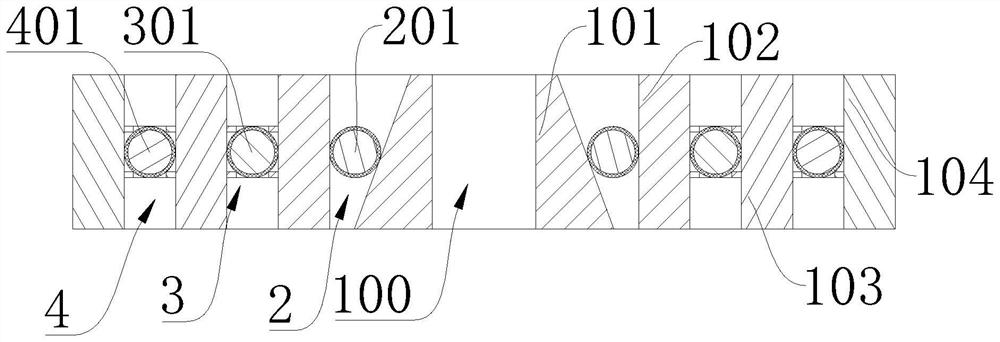

[0060] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, this embodiment is based on Embodiment 1, the contact surface between the above-mentioned first intermediate ring 102 and the above-mentioned second rolling element 301 is a slope, and the above-mentioned second intermediate ring 103 and the above-mentioned The contact surface of the second rolling element 301 is an inclined surface.

[0061] In this embodiment, the contact surface between the first intermediate ring 102 and the second rolling element 301 is an inclined surface, and the contact surface between the second intermediate ring 103 and the second rolling element 301 is an inclined surface, so that the second rolling layer 3 It can bear axial force, and the direction of its slope can be opposite to the direction of the slope of the bearing inner ring 101, which ensures that the three-layer bearing can bear axial force in different directions.

[0062] In some implementations of this embodiment, the contact surface b...

Embodiment 3

[0065] Such as figure 1 , 2 , 3, 4, 5, 6, 7, the above-mentioned first rolling layer 2, the above-mentioned second rolling layer 3 and the above-mentioned third rolling layer 4 are axially arranged.

[0066] In the above embodiment, the above-mentioned first rolling layer 2, the above-mentioned second rolling layer 3 and the above-mentioned third rolling layer 4 are axially arranged, and the axial arrangement greatly improves the bearing capacity of the axial force of the three-layer bearing. The scope of application of the three-layer bearing is specified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com