Soft bullet continuous launching device of toy gun and toy gun comprising launching device

A launcher, toy gun technology, applied to spring guns, weapons without explosives, offensive equipment, etc., can solve the problem of unresolved continuous firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

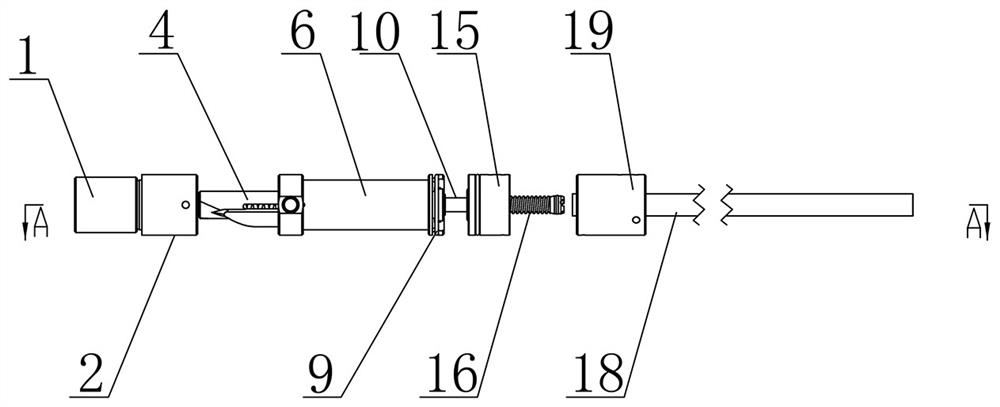

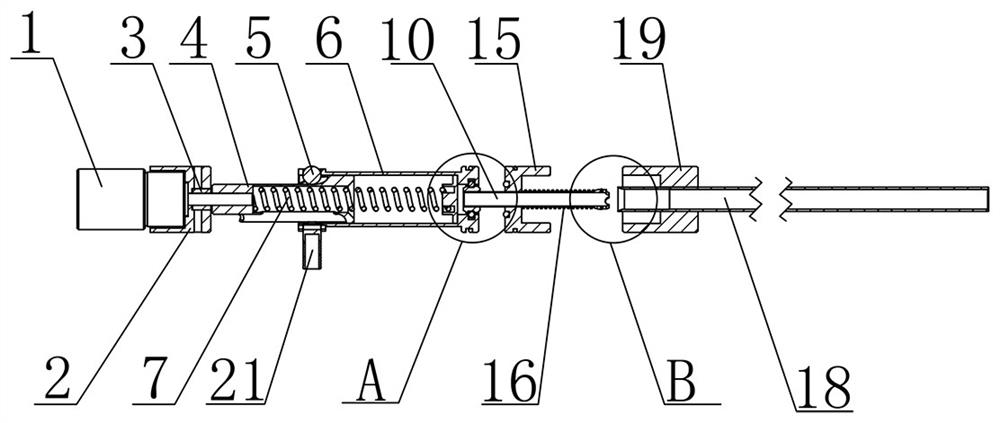

[0038] Such as figure 1 and figure 2 As shown, a toy gun soft bullet continuous firing device of the present invention includes a driving mechanism, a rotating rod 4, a ball 5, an elastic mechanism, a bullet loading handle 21, a guide groove pipe 6, a pushing mechanism, a gun barrel 18 and a gun barrel fixing part 19.

[0039] The driving mechanism drives the rotating rod 4 to rotate in one direction counterclockwise or clockwise. One end of the rotating rod 4 is connected with the driving mechanism, and the other end is inserted into the guide groove pipe 6 . Such as Figure 6 As shown, the rotating rod 4 is provided with a spiral groove, and one end of the guide groove pipe 6 is provided with a circular groove connected with the spiral groove, and the upper spring handle 21 is fixed on the guide groove pipe 6 at a position opposite to the circular groove, and the ball 5 is placed in the circular groove. Inside, the ball 5 rolls in the spiral groove to drive the guide tub...

Embodiment 2

[0049] Such as Figure 10 As shown, a toy gun of the present invention includes: a toy gun soft bullet continuous firing device shown in Embodiment 1 and a shell 20 arranged outside the toy gun soft bullet continuous firing device.

[0050] Such as Figure 11 As shown, the shell 20 is correspondingly provided with a handle hole 22, an observation hole 23, a clip hole 24, and a joint hole 25. Ball 5 just can not fall out. The observation hole 23 is used to observe whether there is a soft bullet in the gun barrel 18, the clip hole 24 is used to install a matching clip, the joint hole 25 is used to install a matching scope, the observation hole 23, the clip hole 24 and the joint hole 25 They are all matching settings for toy guns, and those skilled in the art know how to match the auxiliary facilities for installing toy guns, and will not repeat them here.

[0051] In one embodiment, in order to prevent random movement between the cage 15 and the housing 20 , a third sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com