Extrusion die divergent die structure and preparation method thereof

An extrusion die and split die technology, applied in the field of aluminum extrusion die manufacturing, can solve the problems of complex production steps, long production cycle, low production efficiency, etc., and achieve the advantages of shortening the preparation cycle, saving steel costs, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

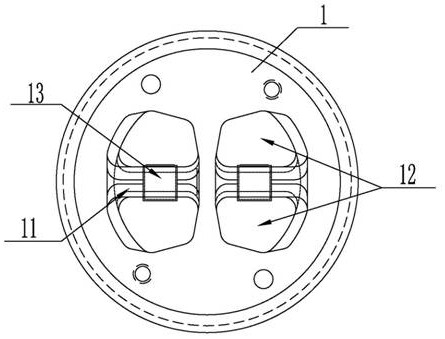

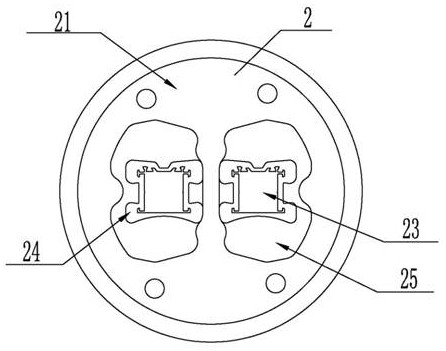

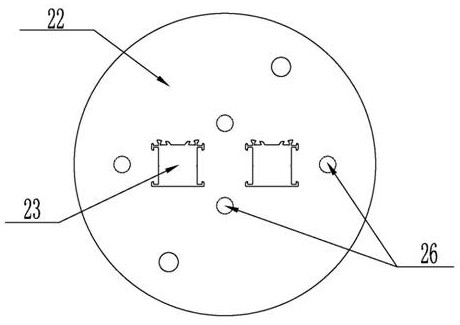

[0028] Similar to the structure of the conventional splitter die, the splitter die structure of the extrusion die of the present invention includes an upper die, a lower die and a die pad that are installed together, and the upper die, the lower die and the die pad are positioned by pins and connected by screws, as Figure 1-4 As shown, it is a schematic structural view of the upper mold 1, the lower mold 2 and the mold pad 3 in an embodiment of the present invention.

[0029] Such as figure 1 As shown, it is a perspective view of the structure of the upper mold 1 in this embodiment, the upper mold 1 has four shunt bridges 11 and four shunt holes 12 divided by the shunt bridges 11 and communicated with the welding chamber of the lower mold 2 ; The bottom of the shunt bridge 11 is provided with a mold core 13 protruding toward the discharge end, and a positioning pin and a screw hole for connecting with the lower die 2 are also provided on the discharge surface.

[0030] Offer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com