Robot laser semi-automatic end socket cutting process

A cutting process, laser cutting technology, applied in the direction of laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of low precision, single cutting angle, complex structure, etc. Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

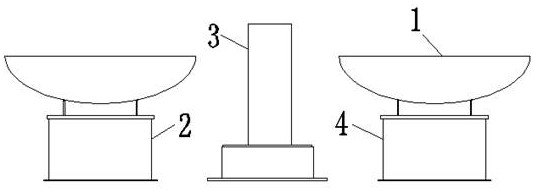

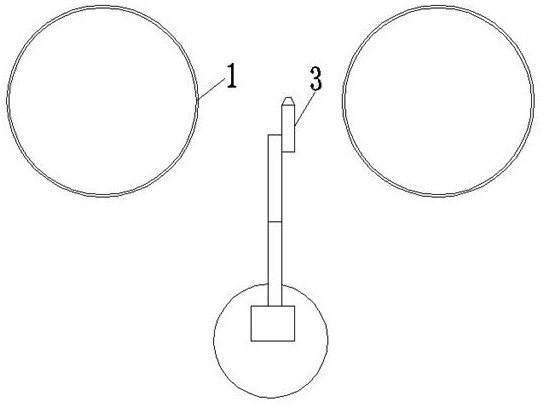

[0023] Such as figure 1 and figure 2 As shown, the robot laser semi-automatic head cutting process of the present invention includes the following steps,

[0024] (1) The head 1 is manually placed on the turntable I2 to adjust the level, and the diameter of the head 1 is 800-2400mm;

[0025] (2) Start the robot 3, and the robot 3 turns to the rotary table Ⅰ2 to complete the horizontal cutting of the head 1 and the internal and external angle bevel cutting. When cutting, the laser cutting gun is facing the safe position outside, and the circumference and height of the head 1 are detected online at the same time and out-of-roundness, stored in the system or printed in the background, the robot 3 is free to run in six axes, and the laser cutting gun uses a 6000W single-module continuous fiber laser;

[0026] (3) Robot 3 resets to the middle after compl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap