Window pulley rubber ring equidistant cutting equipment

An isometric cutting, rubber ring technology, applied in metal processing and other directions, can solve the problems of different lengths of rubber rings, high cutting cost, low accuracy, etc., to achieve consistent cutting length, increase cutting accuracy, and prevent rubber rings. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

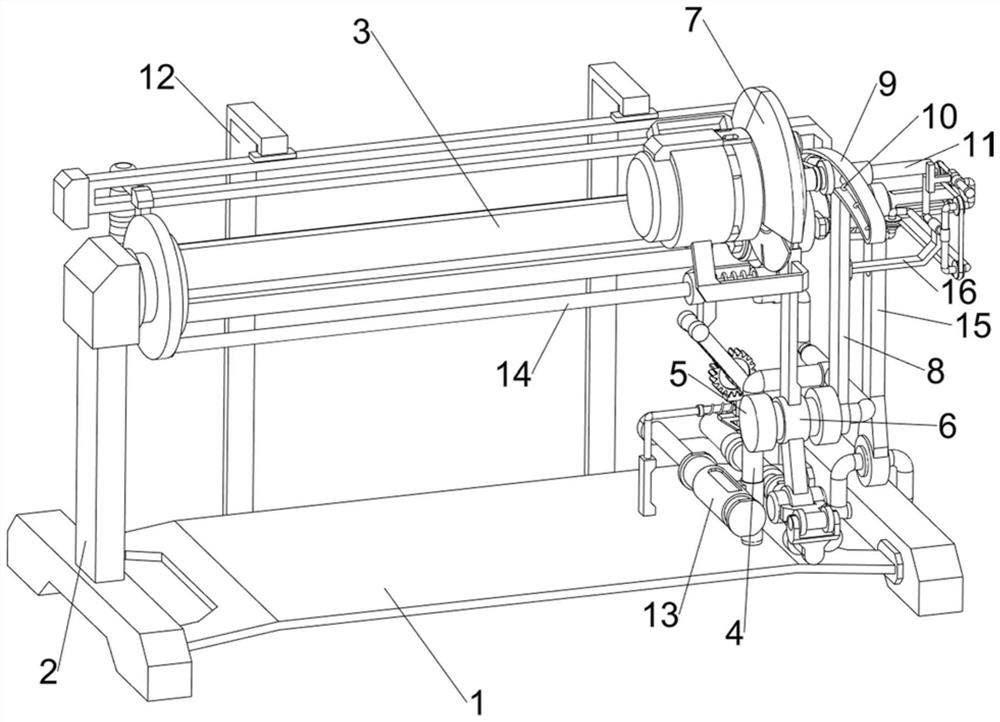

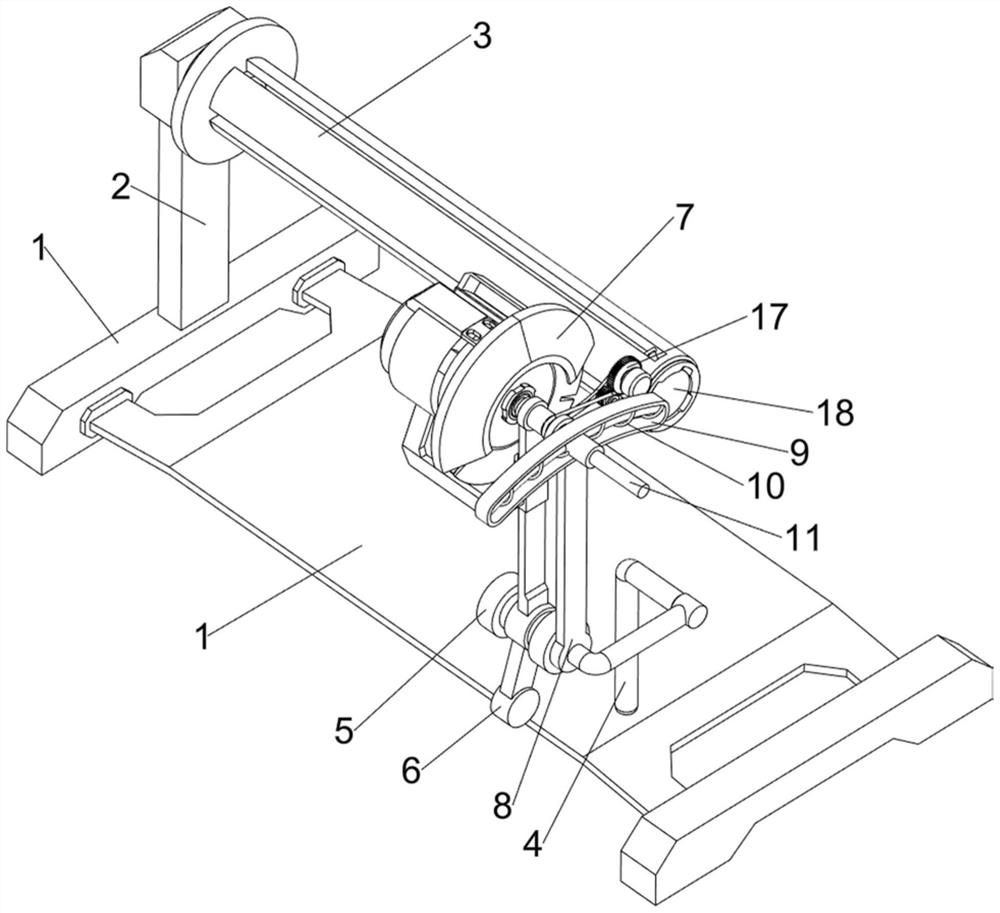

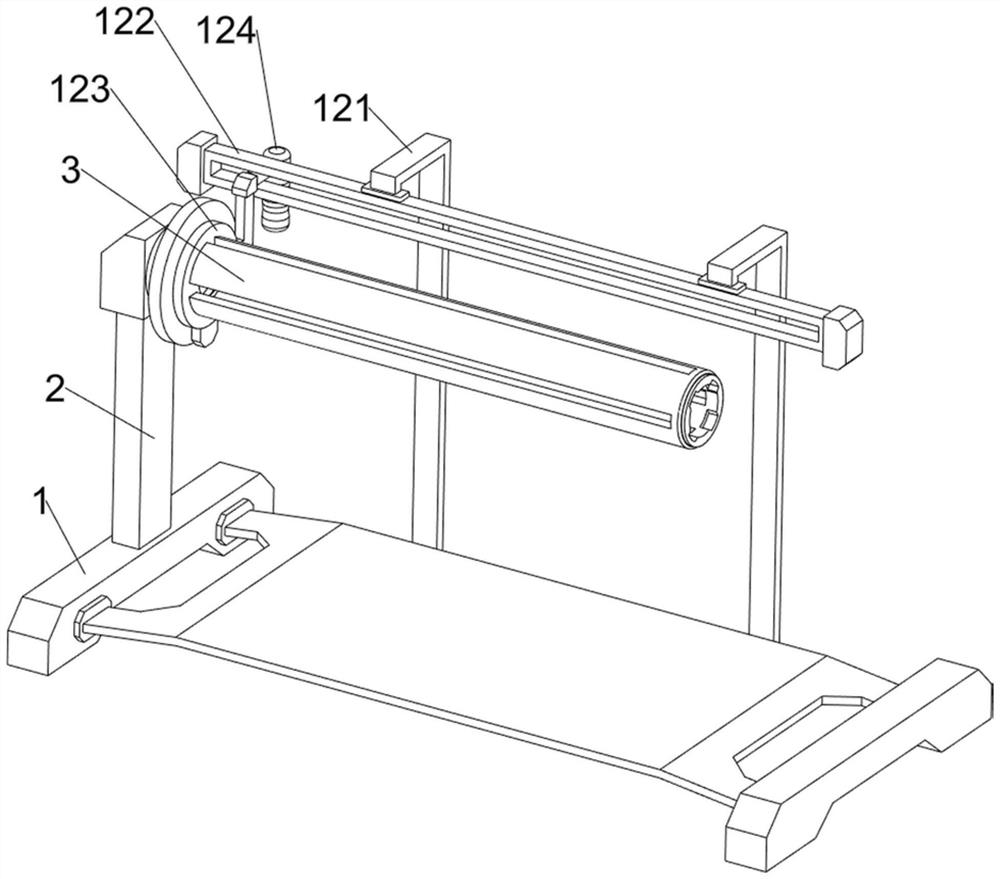

[0107] A window pulley rubber ring isometric cutting equipment such as Figure 1-6 As shown, it includes a base 1, an installation block 2, an upper barrel 3, a first support frame 4, a fixed block 5, a rotating plate 6, a cutting machine 7, a first support plate 8, a first guide frame 9, and a first spring 10. The first sliding block 11, the pushing mechanism 12 and the transmission mechanism 13, the left side of the top of the base 1 is provided with a mounting block 2, the upper right side of the mounting block 2 is rotatably provided with an upper cylinder 3, and the right side of the top of the base 1 is provided with The first bracing frame 4, the front left side of the first bracing frame 4 is provided with fixed block 5, and the rotation type in the middle part of fixed block 5 is provided with rotating plate 6, and cutting machine 7 is installed on rotating plate 6 tops, and cutting machine 7 internal rotary type is connected with For the rotating part, the front side...

Embodiment 2

[0114] On the basis of Example 1, such as figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, a feed mechanism 14 is also included, and the feed mechanism 14 includes a first slide bar 141, a first connecting frame 142, a first fixed frame 143, a third spring 144, a fixed rod 145, a push block 146, a rotating frame 147, The first gear 148, the rack 149, the first guide rod 1410, the triangular block 1411, the top block 1412 and the back-moving spring 1413, the bottom right side of the push plate 123 is provided with the first slide bar 141, and the top of the first support frame 4 rear side is provided with There is a first connecting frame 142, the top of the first connecting frame 142 is provided with a first fixing frame 143, the first fixing frame 143 is slidingly matched with the first sliding rod 141, the material outside the first sliding rod 141 is a damping material, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com