Benzene storage tank drainage device

A drainage device and benzene storage tank technology, applied in the field of coking, can solve the problems of benzene storage tank corrosion, affecting the quality and stability of benzene products, etc., and achieve the effects of reducing benzene content, simple structure, and no leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

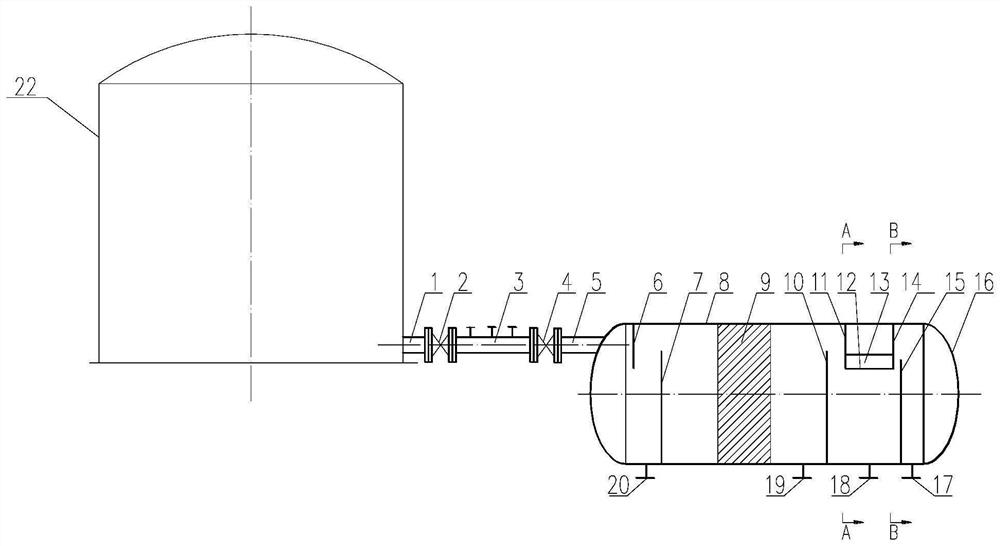

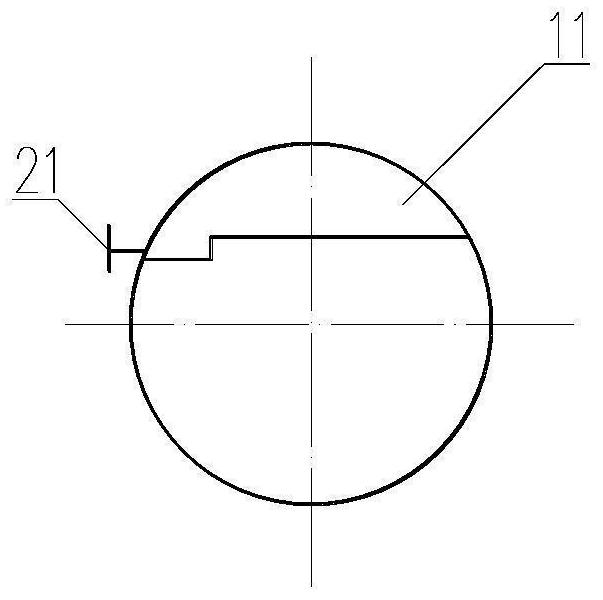

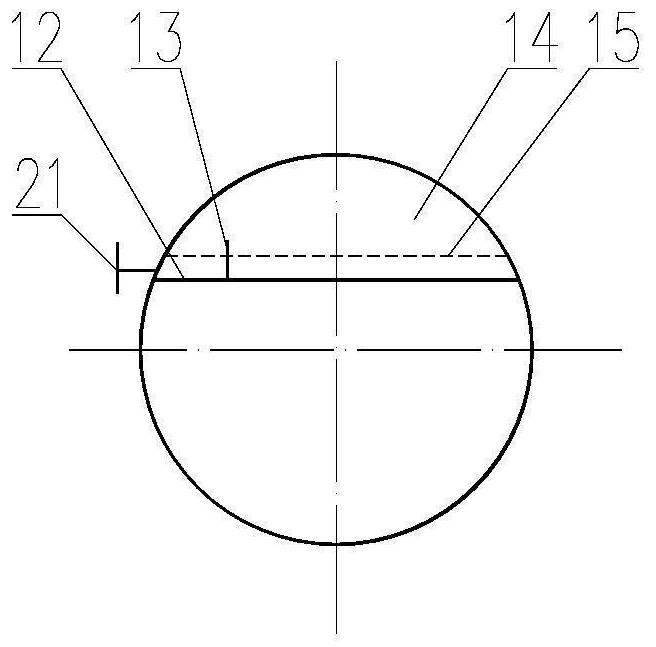

[0024] Such as Figure 1-Figure 3 As shown, a benzene storage tank drainage device of the present invention includes a benzene-water separation tank, a connecting pipeline and an ultrasonic sensor 3; and a benzene full-flow cutting unit. The upper part of the tank body 8 is provided with a water inlet 5, which is connected with the water outlet 1 of the benzene storage tank 22 through a communication pipe; a manual valve 2 and an ultrasonic sensor are sequentially arranged on the communication pipe along the direction of liquid flow. 3 and the electric valve 4; the bottom of the other end of the tank body 8 is provided with a drain port 17; the tank body 8 between the water inlet 5 and the drain port 17 is successively provided with an upper baffle plate 6, a partition plate 7, a coalescer 9, and a lower The baffle 10, the benzene full-flow cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com