Automatic water draining valve for locomotives

A technology of automatic drainage and drainage valve, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of increasing the workload of use and maintenance, inoperability, etc., achieving a high degree of automation, fast action response, and small air loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

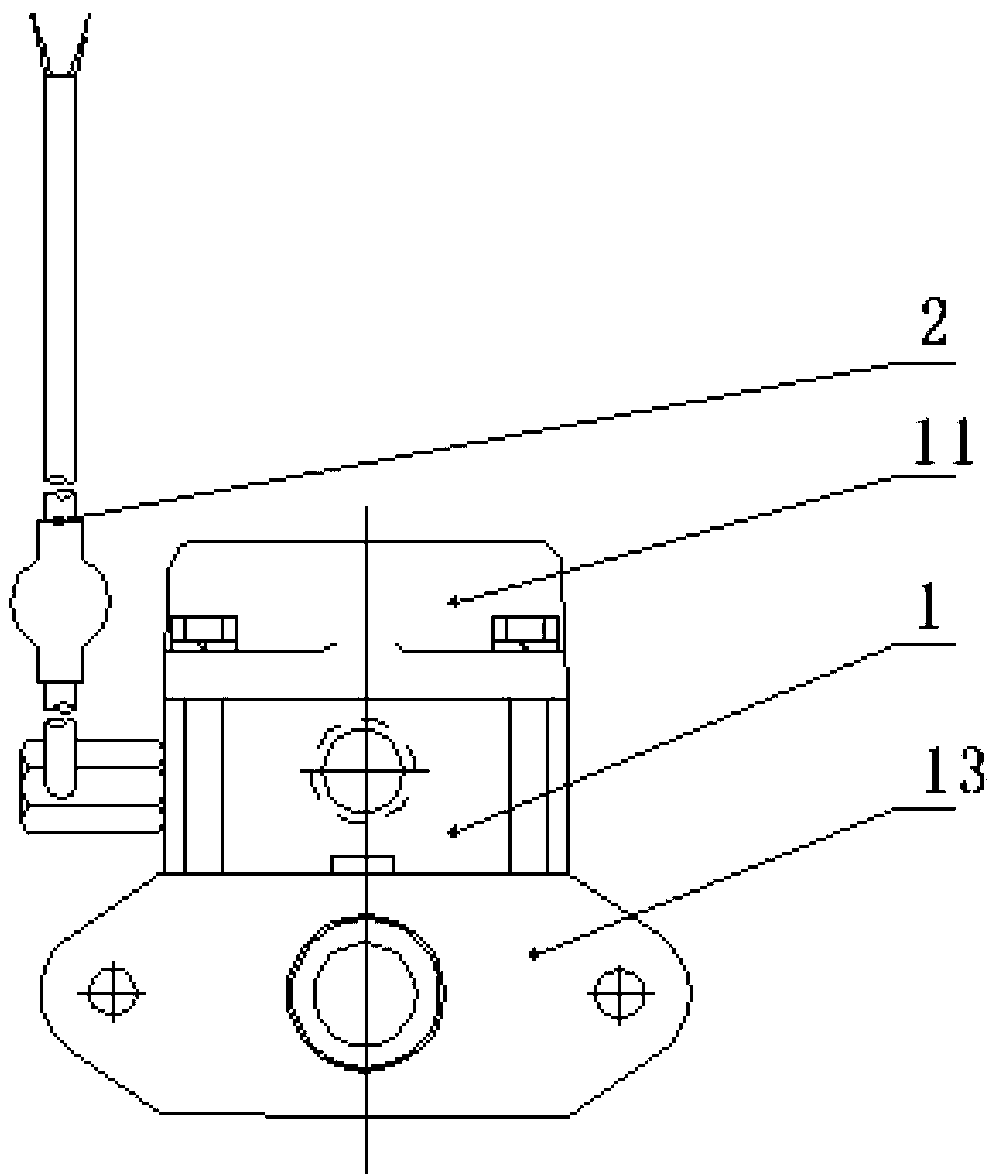

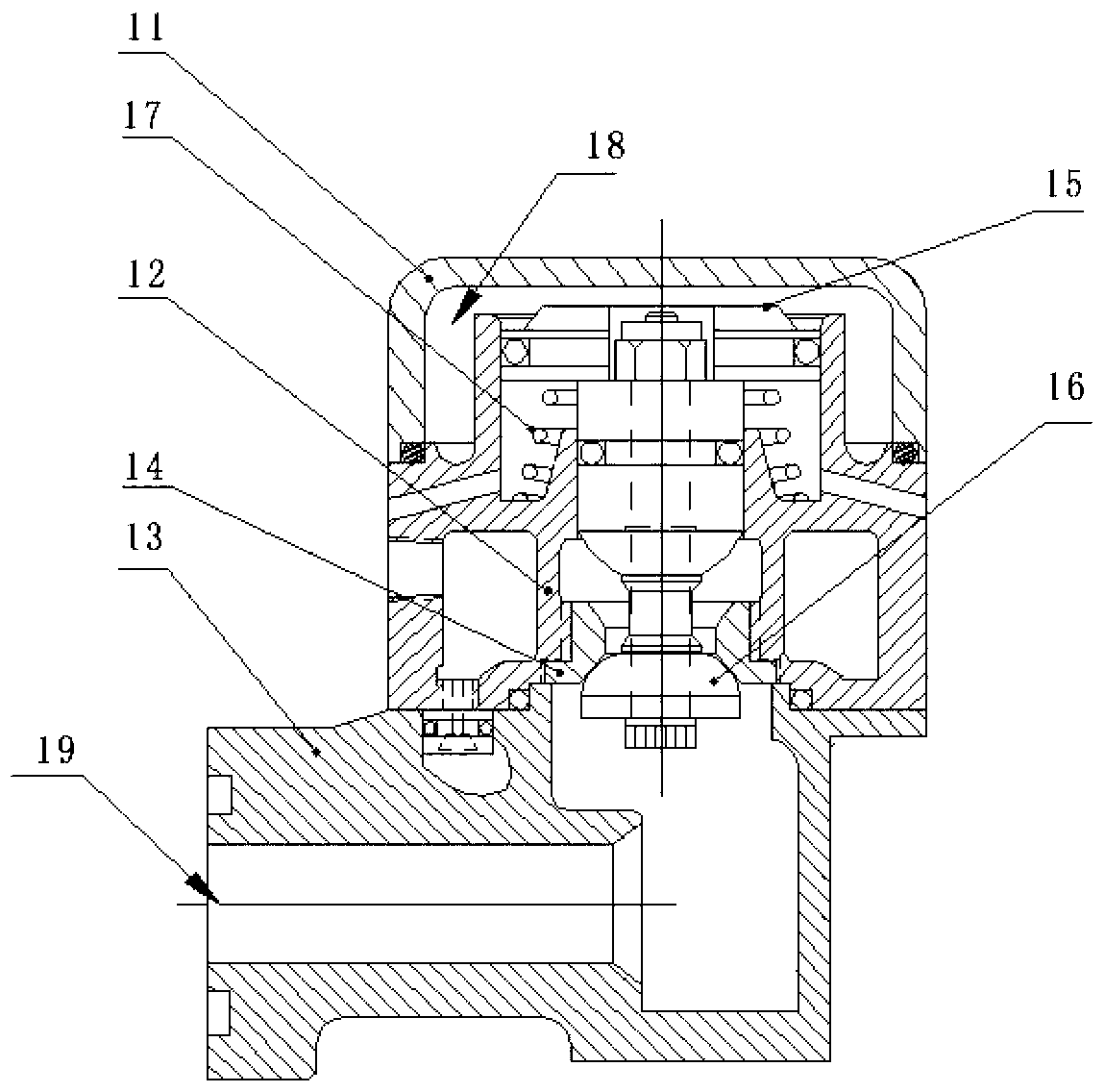

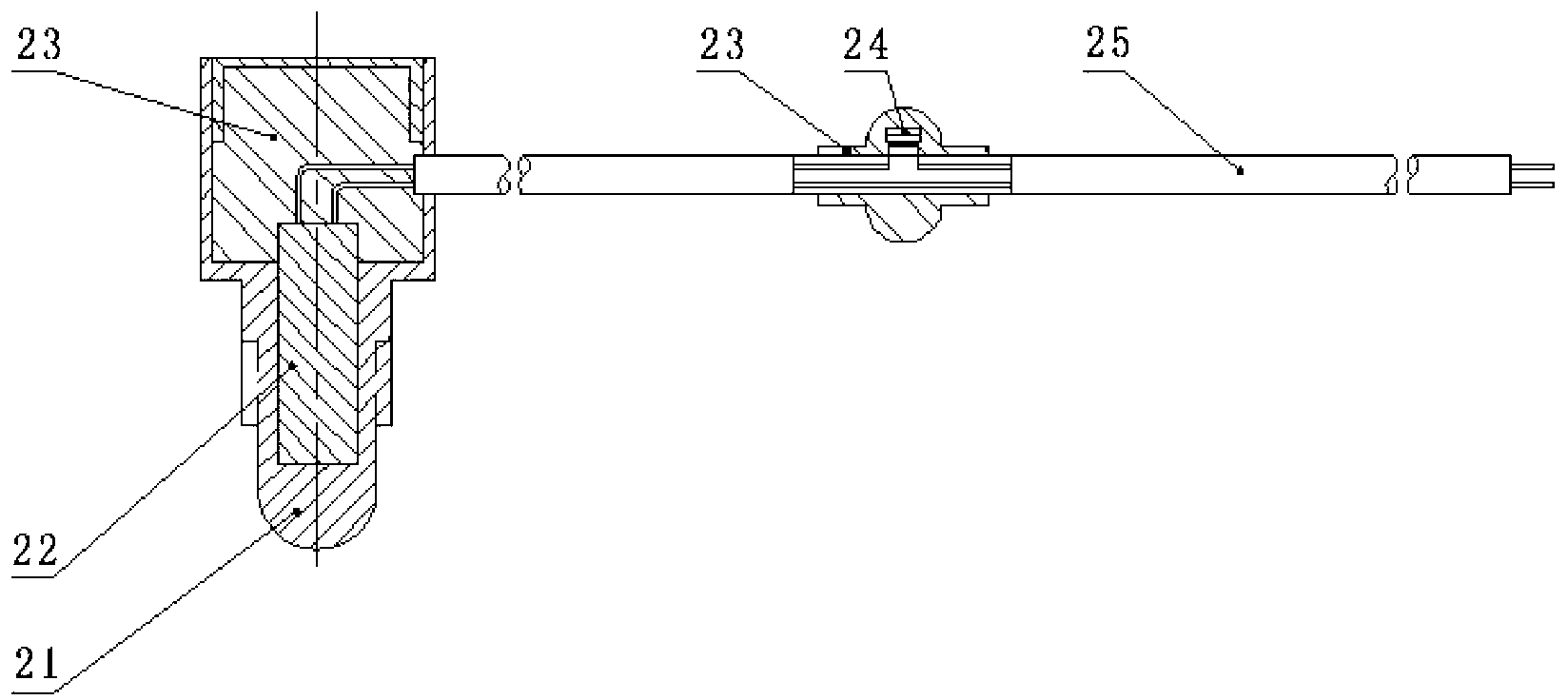

[0016] An automatic drain valve for a locomotive, characterized in that the automatic drain valve is composed of a drain valve 1 and a heating rod 2;

[0017] The drain valve 1 is composed of a valve cover 11, a valve body 12, a mounting bracket 13, a replaceable valve core seat 14, a piston assembly 15, a Teflon valve 16 and a spring 17;

[0018] The upper part of the valve body 12 is provided with a spring 17 and the piston assembly 15 in turn, the lower part of the valve body 12 is provided with a replaceable valve core seat 14, the Teflon valve 16 is arranged on the replaceable valve core seat 14, and the valve cover 11 is provided with At the upper end of the valve body 12, an air chamber 18 is formed between the valve cover 11 and the valve body 12, and the air chamber 18 communicates with the control air pipe; the valve body 12 is provided with a heating hole for installing a heating rod, and the heating hole is provided with threaded;

[0019] The mounting bracket 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com