Large-area preparation method of high-stability high-saturation photonic crystal structure yarn-producing fabric

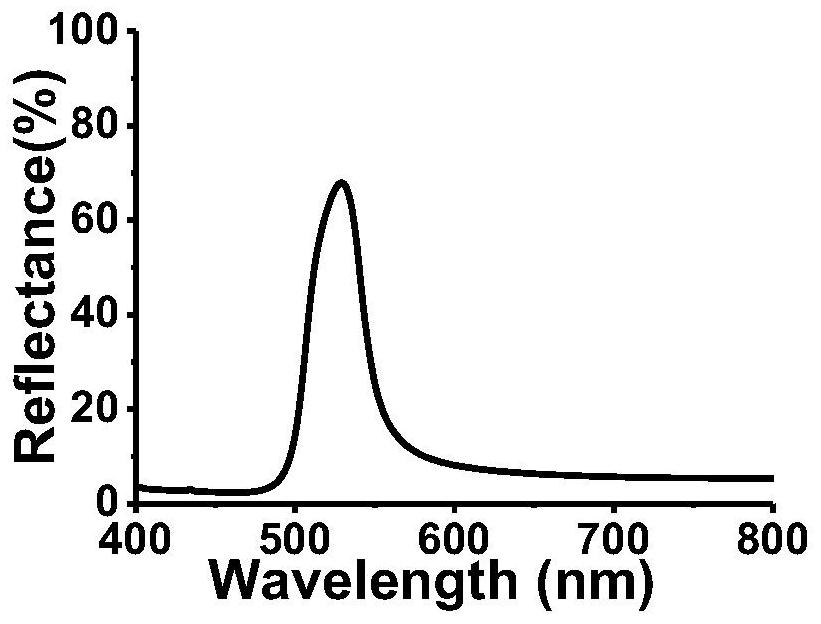

A photonic crystal, high-stability technology, applied in animal fibers, plant fibers, textiles and papermaking, etc., can solve the problem of reducing structural color saturation, and achieve the consistency of improving stability, high stability and high saturation , the effect of bright structural color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

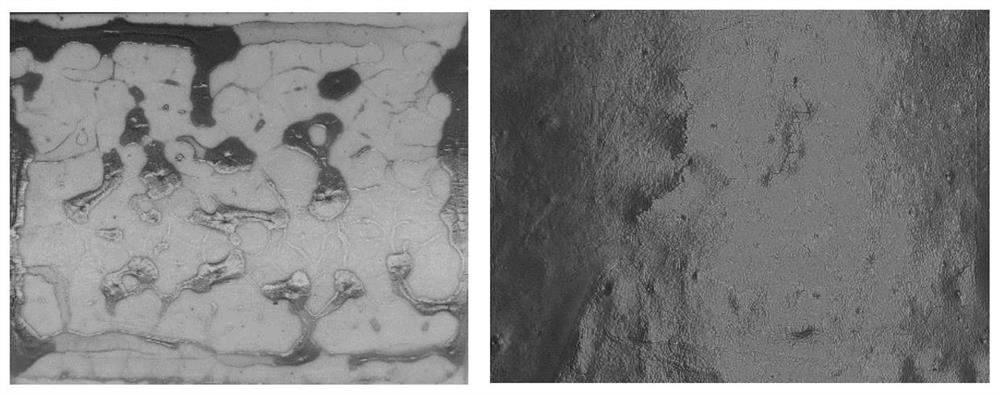

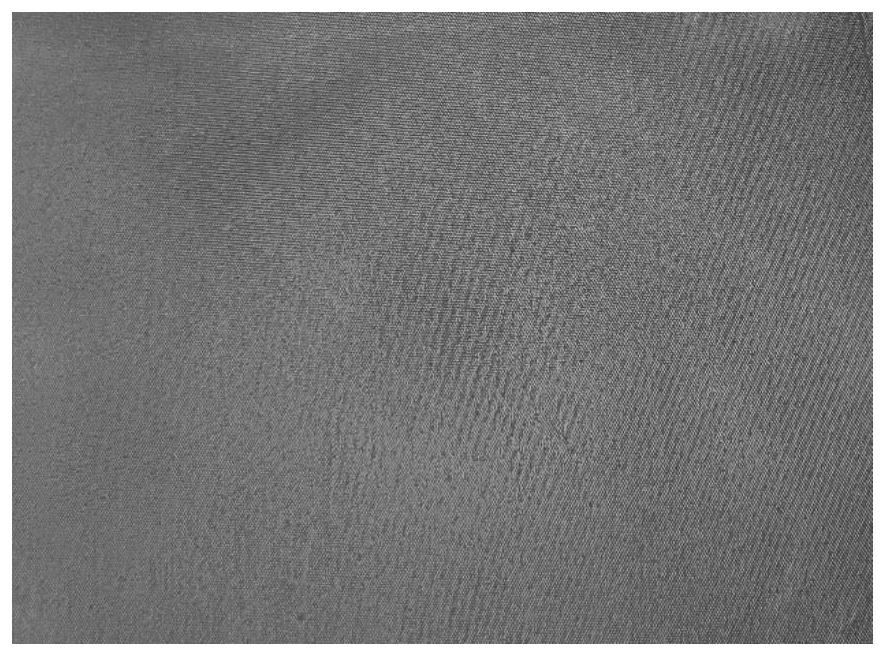

[0045] A method for preparing a large-area color-producing fabric with a high-stability and high-saturation photonic crystal structure. The steps of the method are as follows:

[0046] (1) Surface modification of textile substrates: Scrape-coat 8 g / m2 of special polymer ① (PUE1401) on the surface of polyester fabric and place it in a heating device to heat and cure at 80°C for 5 minutes to form a film;

[0047] (2) Configure 150nm PS nano-microsphere dispersion (nano-microsphere 15wt%, carbon black 0.02wt%, activator: fatty alcohol polyoxyethylene ether 1wt%, surplus is water), make the dispersion liquid by wire rod induction Uniform distribution on the surface of the fabric with the special polymer layer obtained in (1);

[0048] (3) Place the compound obtained in (2) in a static heating device (temperature 50°C, humidity 50%) for 10 minutes to complete the assembly of nanospheres, the activation and migration of the interface layer, and the stable curing of the entire compou...

Embodiment 2

[0050] A method for preparing a large-area color-producing fabric with a high-stability and high-saturation photonic crystal structure. The steps of the method are as follows:

[0051] (1) Surface modification of textile substrates: 12 g / m2 special polymer (PUE-2013) was prepared on the surface of polyester fabric by film transfer method ① (PUE-2013) was placed in a heating device and heated at 80°C for 90 seconds to form a film;

[0052] (2) configuration 200nm PMMA nano-microsphere dispersion (nano-microsphere 20wt%, carbon black 0.03wt%, activator: polyoxyethylene sorbitan fatty acid ester 2wt%), make the dispersion in ( 1) The surface of the obtained fabric with the special polymer layer is evenly distributed;

[0053] (3) Place the compound obtained in (2) in a continuous hot air heating device (temperature 60°C, humidity 60%) for 7 minutes to complete the assembly of nanospheres, the activation and migration of the interface layer, and the stable curing of the entire com...

Embodiment 3

[0055]A method for preparing a large-area color-producing fabric with a high-stability and high-saturation photonic crystal structure. The steps of the method are as follows:

[0056] (1) Surface modification of textile substrates: Scrape-coat 16 g / m2 special polymer ① (PUE1650) on the surface of cotton fabrics and place in a heating device to heat and cure at 100°C for 3 minutes to form a film;

[0057] (2) configuration 250nm P (St-MMA) nano microsphere dispersion (nano microsphere 30wt%, carbon black 0.05wt%, activator: alkylphenol polyoxyethylene ether 3wt%, surplus is water), by magnetic Rod induction makes the dispersion evenly distributed on the surface of the fabric with special polymer layer obtained in (1);

[0058] (3) Place the compound obtained in (2) in a static heating device (temperature 70°C, humidity 70%) for 5 minutes to complete the assembly of nanospheres, the activation and migration of the interface layer, and the stable curing of the entire compound to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap