Cover-excavation type subway station middle stand column high-precision construction method

A construction method and technology for subway stations, which can be used in artificial islands, water conservancy projects, infrastructure projects, etc., and can solve problems such as inclinations that are difficult to find

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

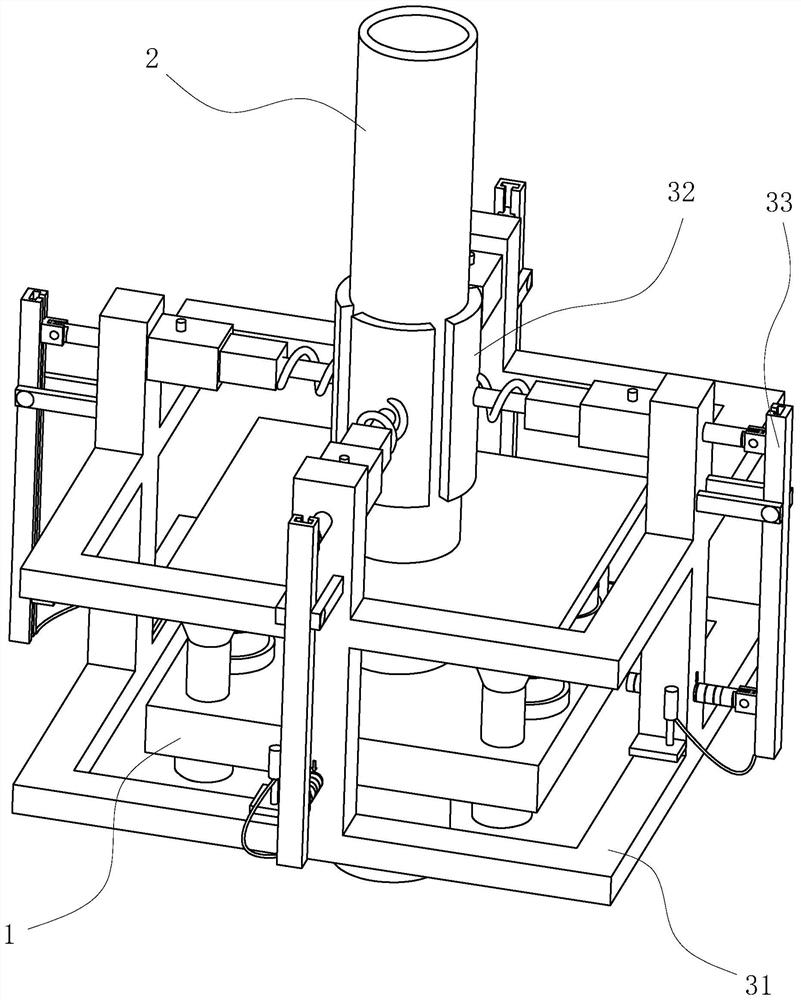

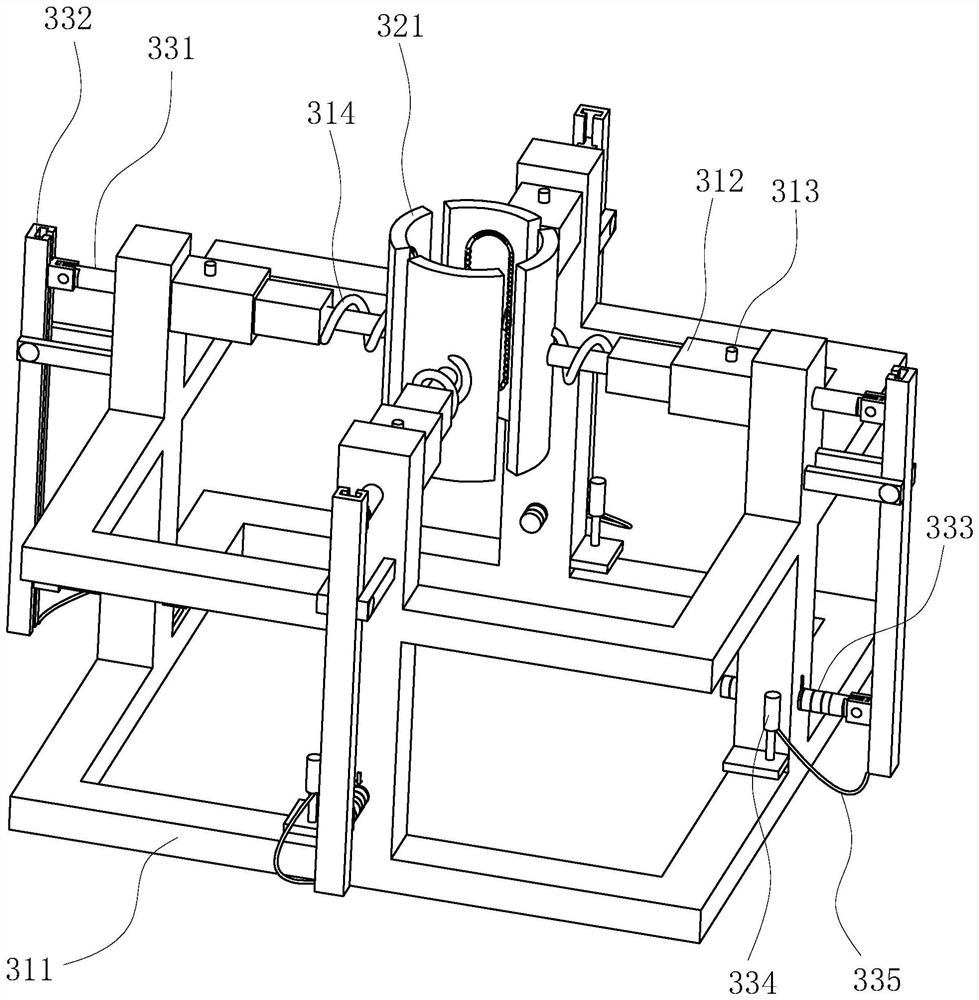

[0033] The following is attached Figure 1-4 The application is described in further detail.

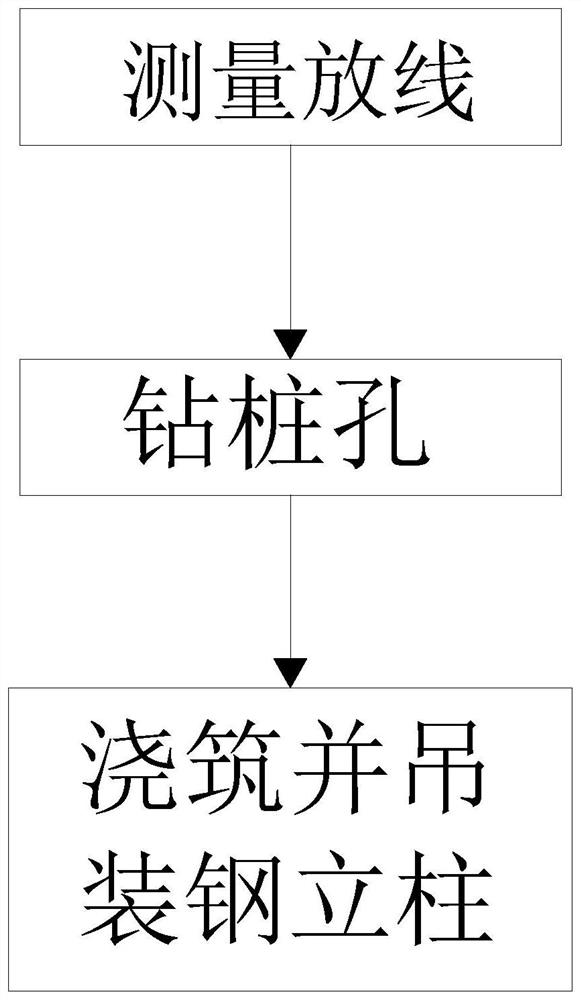

[0034] The embodiment of the present application discloses a high-precision construction method for a central column of a cover-and-excavation subway station. refer to figure 1 and figure 2 A high-precision construction method for a central column of a cover-excavated subway station comprises the following steps:

[0035] S1. Surveying and setting out: Level and harden the construction site. According to the construction drawings and on-site wire control points, use the total station to measure the pile position, and directly fix the point or drive the wooden pile into the fixed point according to the geological conditions.

[0036] S2. Drilling pile holes: Before drilling pile holes, manually dig a test pit to the undisturbed soil or dig a 2m deep test pit to effectively protect the unidentified underground pipelines. A steel casing is buried at the opening of the designed pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com