Mechanical sealing device for pump and using method

A mechanical seal device and pump technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of fluid leakage in the pump, reduced mechanical seal performance, poor connection tightness, etc., to simplify the structure and ensure stability. , the effect of improving the tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

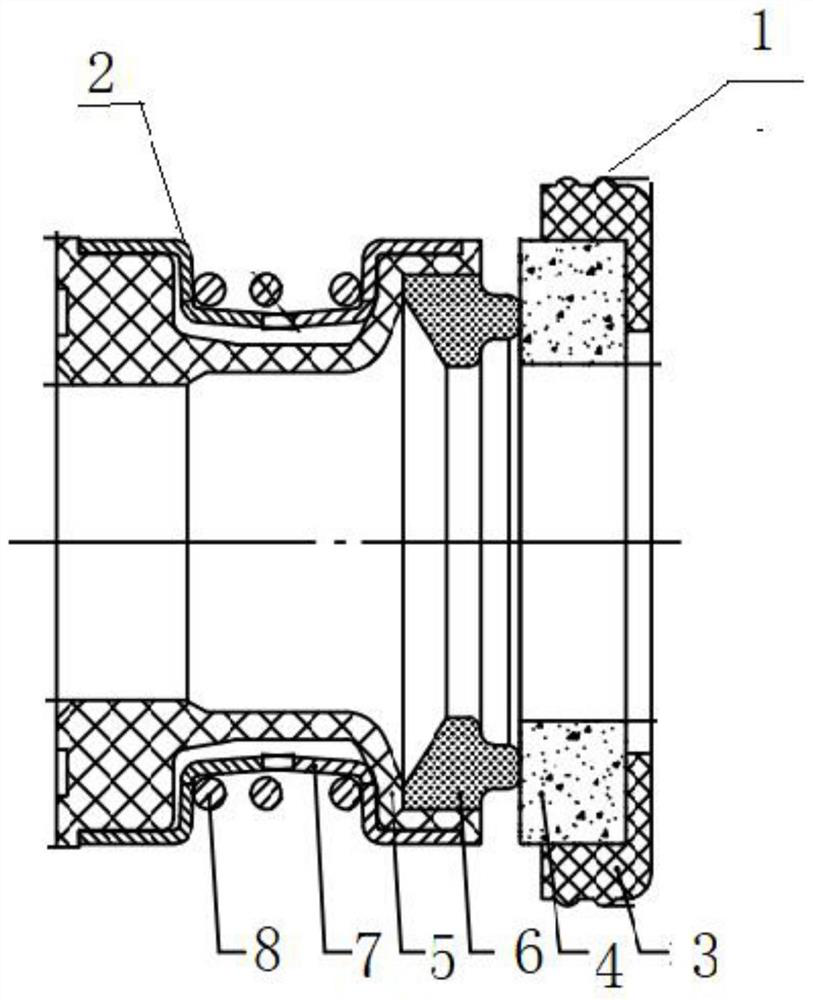

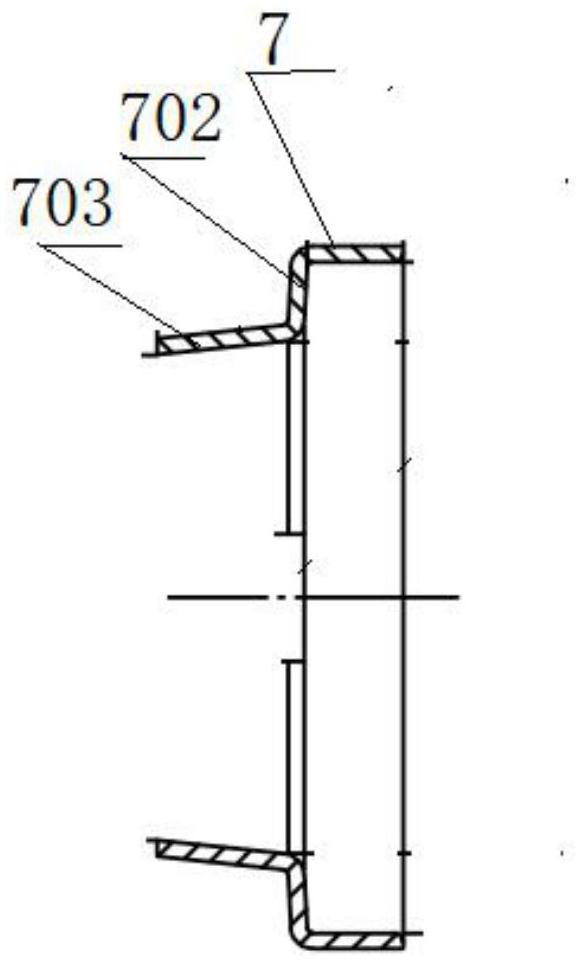

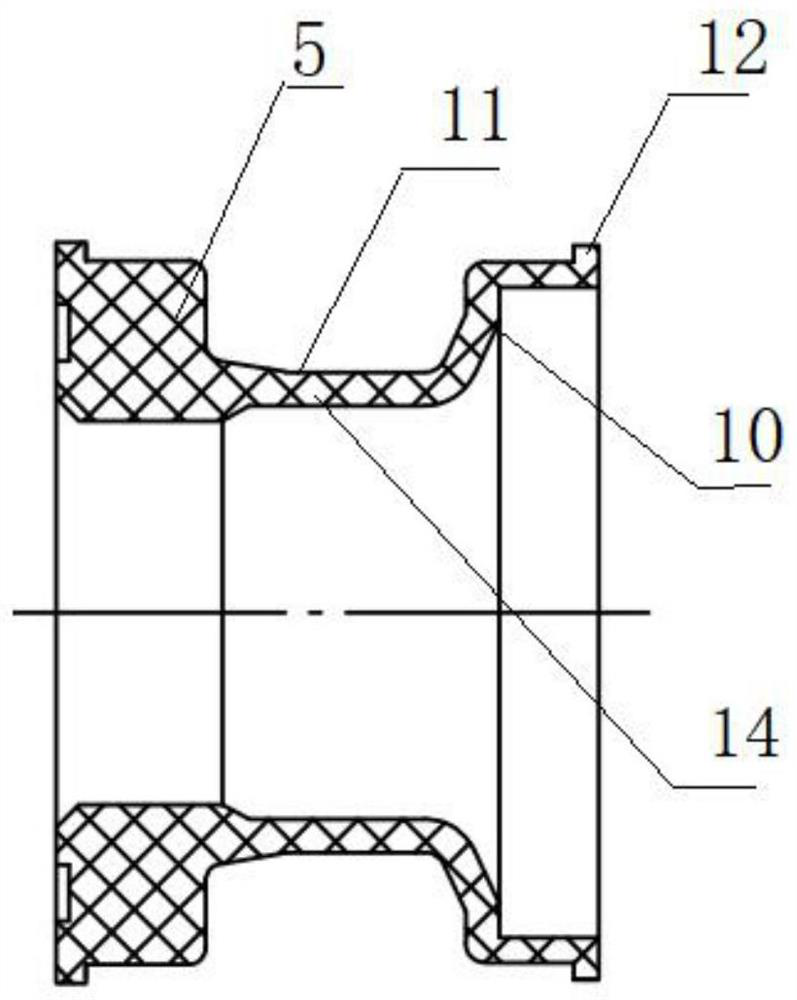

[0030] Embodiment: a mechanical seal device for a pump, including a static ring assembly 1 and a moving ring assembly 2 that cooperate with each other, and the moving ring assembly 2 includes a moving ring rubber 5, a moving ring 6 and a spring 8 arranged coaxially; The ring 6 is set close to the static ring assembly 1 and fixed in one end of the moving ring rubber 5. The moving ring rubber 5 is provided with a pair of positioning sleeves 7 which are oppositely arranged and can be snapped together. The spring 8 is set in a pair of positioning sleeves. 7; the moving ring rubber 5 includes a moving ring rubber body 14, the middle part of the moving ring rubber body 14 is provided with a ring groove 11, and a pair of positioning sleeves 7 are arranged in the ring groove 11; the moving ring rubber body 14 An engaging groove 10 is provided in one end, and positioning protrusions 12 are provided at both ends of the moving ring rubber body 14, and the ends of the positioning sleeve 7 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap