90-degree power valve capable of automatically dredging

An automatic and dynamic technology, applied in the direction of valve lifter, valve device, engine components, etc., can solve the problems of silted powder, unable to solve the problem of powder penetration and deposition, and increase the friction of the gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

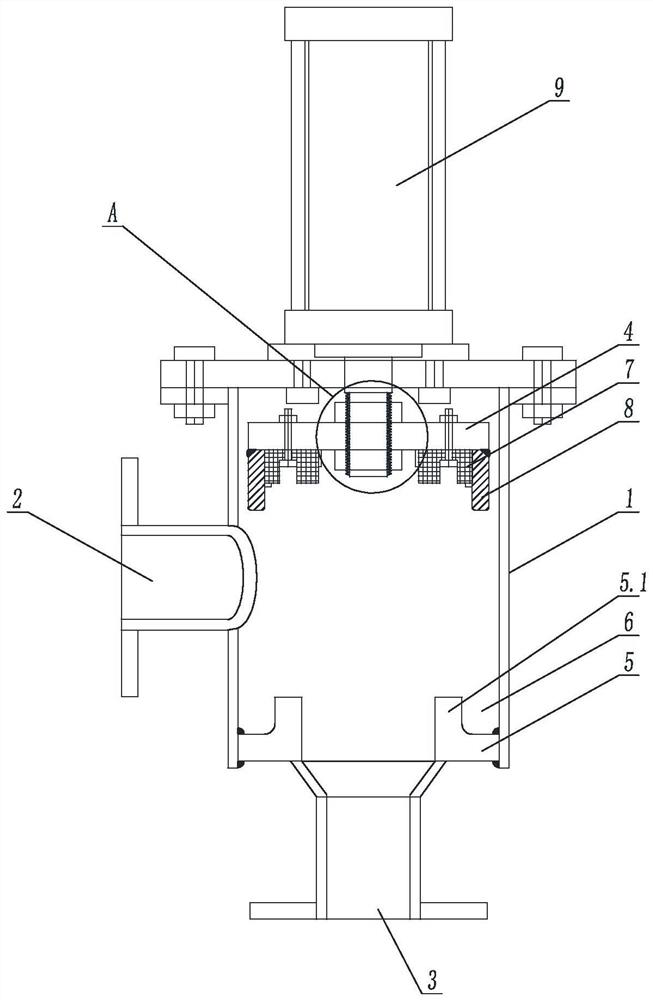

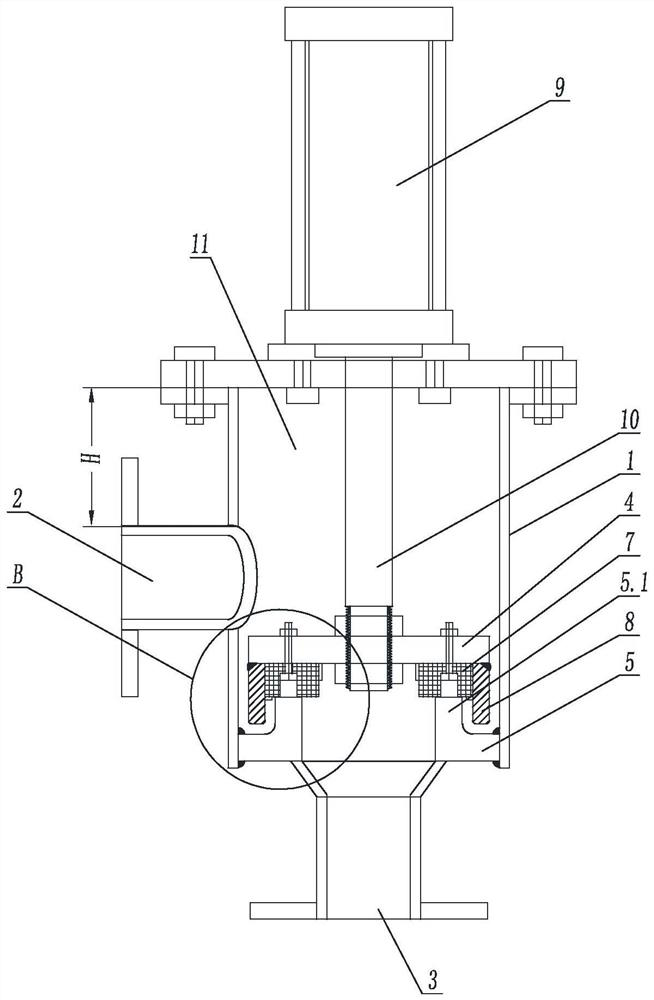

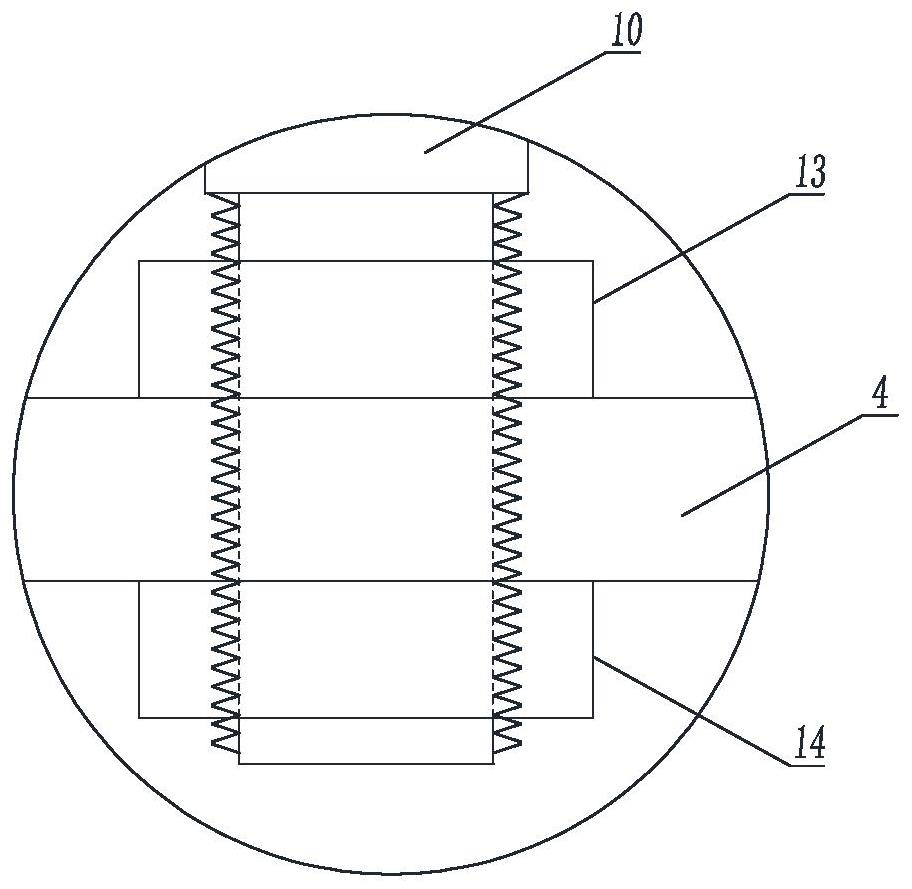

[0021] figure 1 It is a structural schematic diagram of the present invention; figure 2 Schematic diagram of the structure of the valve closed; image 3 for figure 1 Enlarged view of Part A of ; Figure 4 for figure 2 Enlarged view of Part B of ; Figure 5 It is a schematic diagram of the structure that the valve is about to close; Figure 6 Side view of the self-dredging annular toothed ring. Such as Figures 1 to 6 As shown, a 90-degree power valve for automatic desilting includes a valve body 1, the top of the valve body 1 is sealed by an upper cover plate, the inlet port 2 is set on one side of the valve body 1, and the outlet port 3 is set on the valve body 1 The bottom end, the inlet end 2 and the outlet end 3 are at 90 degrees, and also include a lower pressure plate 4 and an annular bottom plate 5, the lower pressure plate 4 and the annular bottom plate 5 are arranged in the valve body 1, and the annular bottom plate 5 is arranged at the bottom of the valve bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com