An automatic desilting clear water tank of a sandstone production wastewater treatment system and its use method

A technology for production wastewater and treatment system, applied in separation methods, chemical instruments and methods, precipitation separation, etc., can solve the problems of high labor intensity, reduce the operating rate of wastewater treatment system, and turbid production water, so as to reduce labor intensity and improve Start-up rate and production efficiency, avoid the effect of manual dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

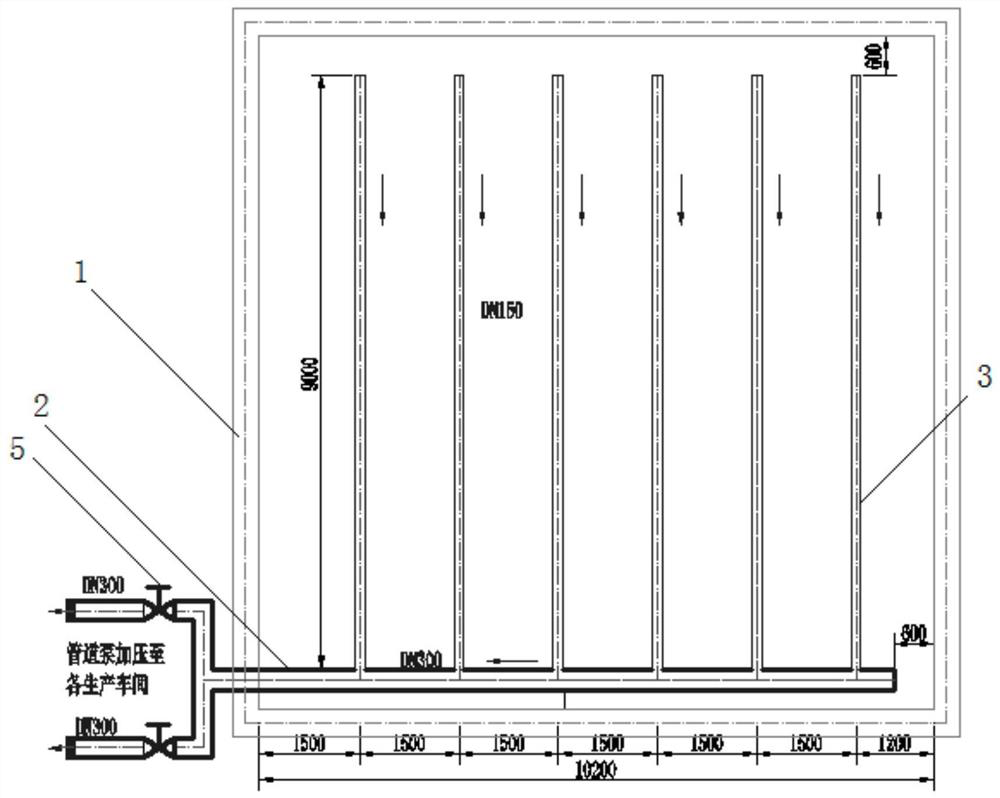

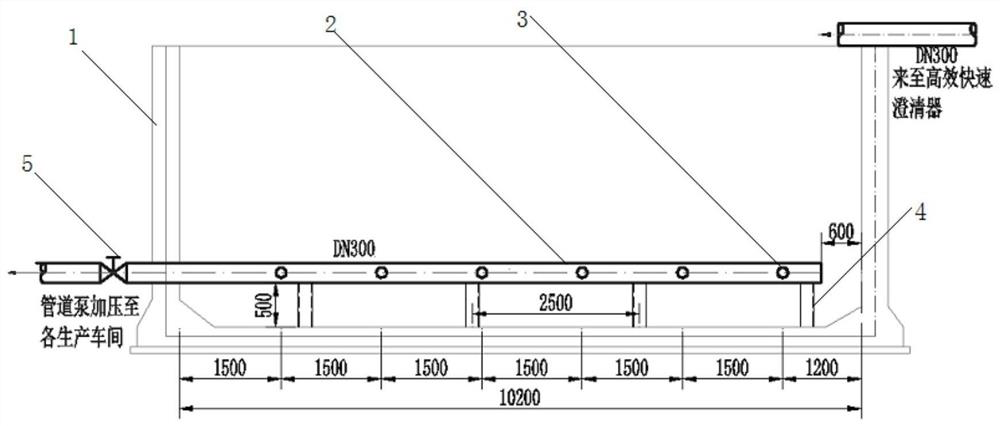

[0016] see Figure 1 to Figure 5 shown.

[0017] An automatic dredging clear water pool of a gravel production wastewater treatment system according to the present invention comprises: a clean water pool body 1, a main water pipe 2 installed through the bottom of the clean water pool body 1, a water branch pipe 3 connected with the main water pipe 2, and a main water pipe 2 And the water branch pipe 3 and the inner wall of the clear water tank body 1 are not in contact with each other at a distance, and the water branch pipe 3 is provided with a water inlet 31, and the water body flows into the water branch pipe 3 through the water inlet 31 in the cavity of the clear water tank body 1 Discharge through main water pipe 2.

[0018] The clear water pool body 1 is a cavity with equal length and width, and the distance between the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com