Petrochemical engineering digital delivery process management and control method

A petrochemical engineering and process management technology, applied in data processing applications, instruments, manufacturing computing systems, etc., can solve problems such as limited data use scope, lack of connection between data application systems, and reduced data accuracy, reducing manual verification. Work, ensure ease of use, and ensure the effect of reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

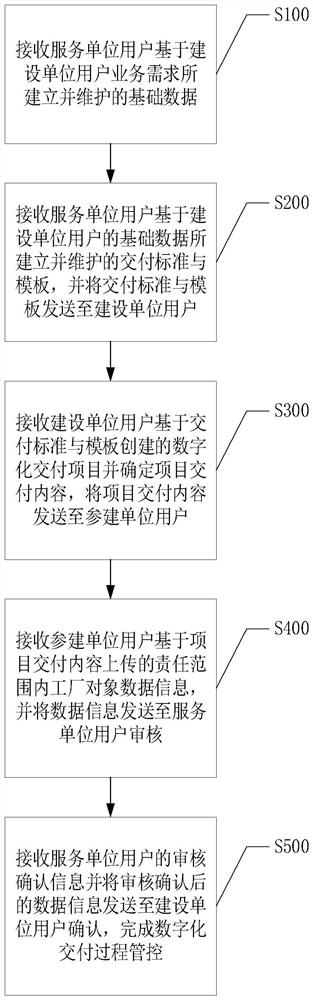

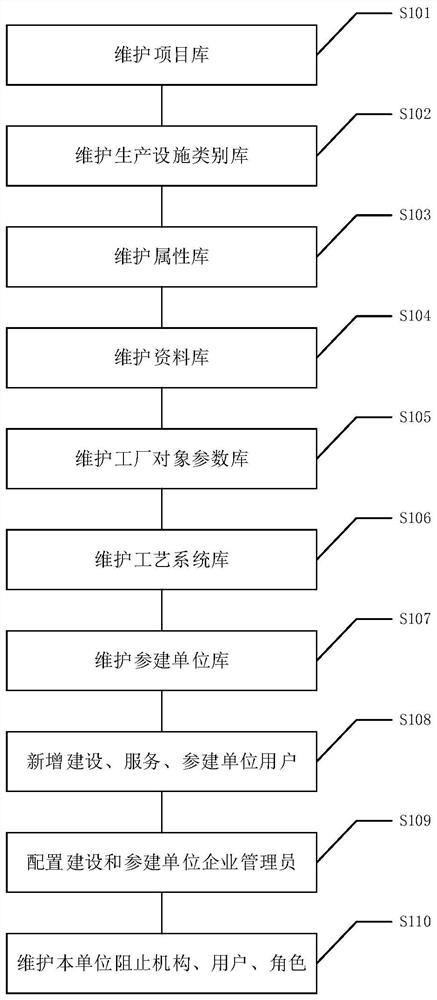

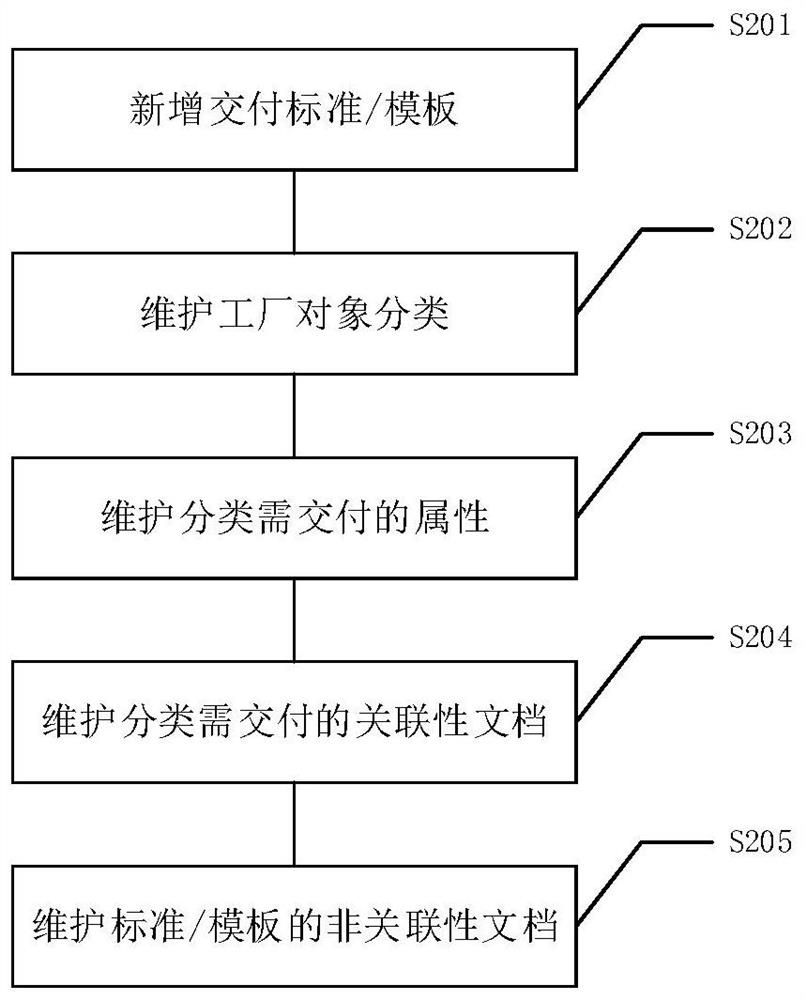

Method used

Image

Examples

specific example

[0100] In order to improve the query performance, this system adds the function of multi-value index, and creates a composite index by encoding factory objects and attributes to improve query efficiency. A multi-valued index is also called a composite index, and is indexed according to the frequency of fields appearing in query conditions. In a composite index, records are sorted first by the first field. For records with the same value on the first field, the system will sort according to the value of the second field, and so on. Therefore, only when the first field of the compound index appears in the query condition, the index can be used. Therefore, placing the field with high application frequency in front of the compound index will make the system use the index as much as possible and play the index role. The reason why multi-value indexes are used in this system is because these data are all based on fixed items, production facilities, factory objects, and attribute c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com