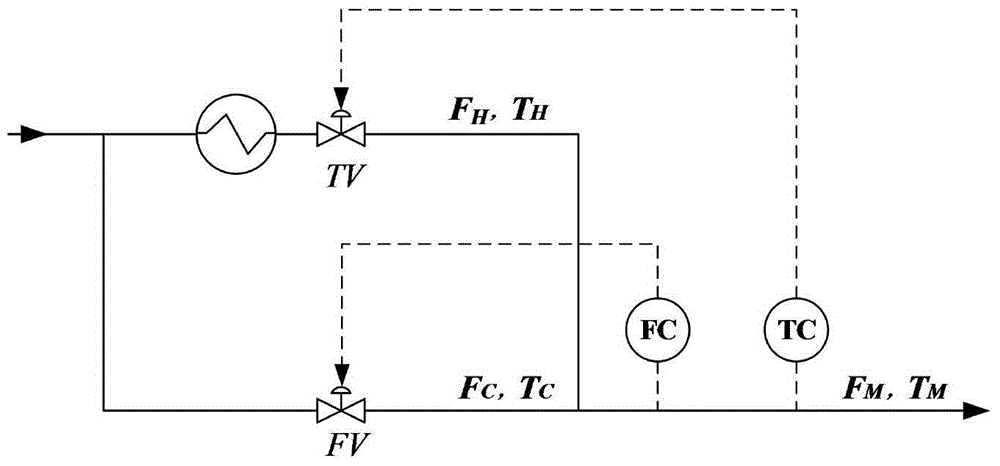

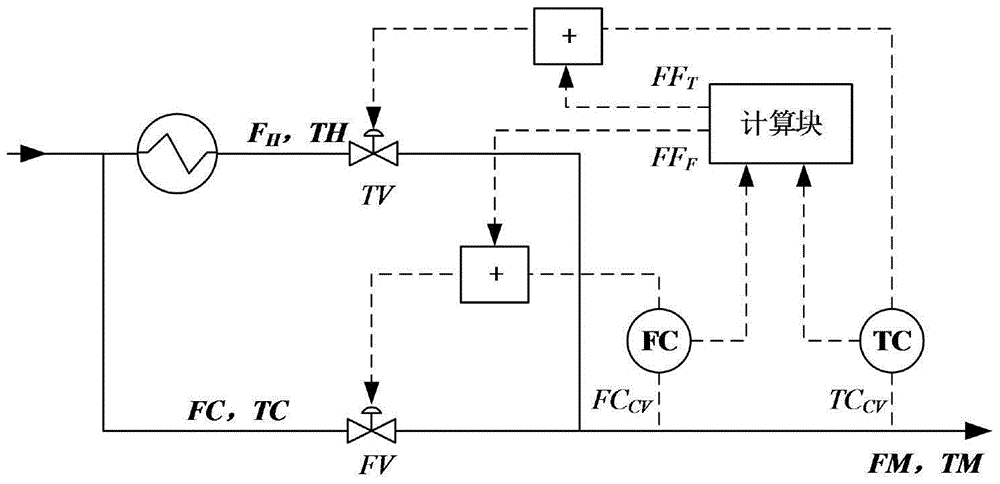

Temperature and flow decoupling control structure and method

A technology of decoupling control and temperature controller, applied in non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve the problems of untimely control, inability to achieve precise control, divergence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

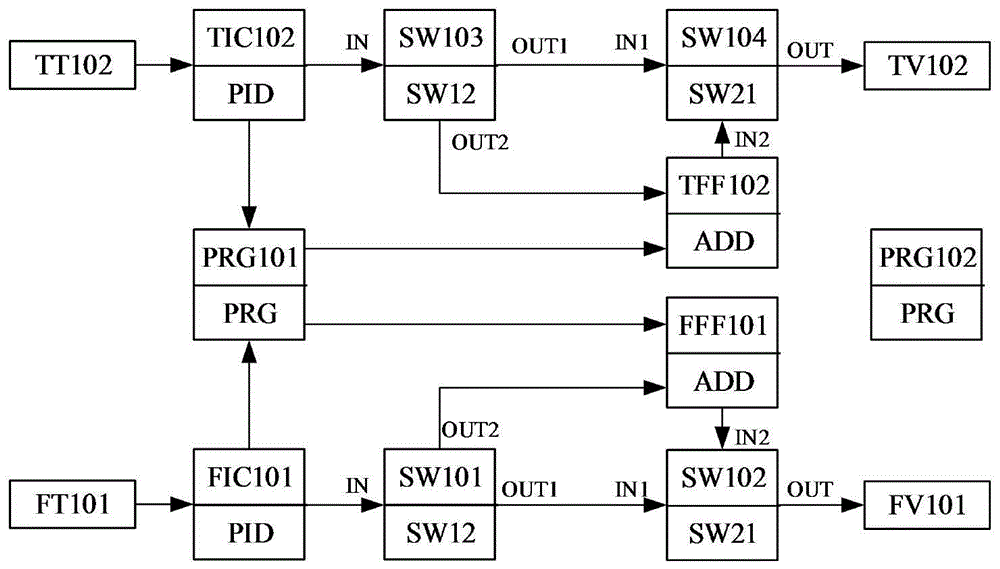

[0161] In conjunction with the specific embodiments, the present invention is further explained as follows.

[0162] like Figure 5-8 As shown, the temperature and flow decoupling control of the mixed regeneration gas in the hydrogen dryer, the set value of the mixed regeneration gas temperature is TIC340197.SV, the measured value of the mixed regeneration gas temperature is TIC340197.PV; the set value of the mixed regeneration gas flow rate is FIC340195 .SV, mixed regeneration gas flow measurement value is FIC340195.PV.

[0163] (1) The flow rate is adjusted individually, such as Figure 6 shown.

[0164] In the original system, keep the temperature set value unchanged at 232°C, and when the flow set value increases from 1.5t / h to 1.8t / h, the maximum temperature deviation from the set value will be 10°C; the flow set value will change from 1.8t When / h is reduced to 1.5t / h, the maximum temperature deviation from the set value is 9.6°C.

[0165] After the decoupling contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com