Circuit board tape and butt joint method thereof

A circuit and board roll technology, applied in the directions of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of inability to carry out the process, the variation of the transmission hole distance, etc., and achieve the effect of the number of circuit layouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

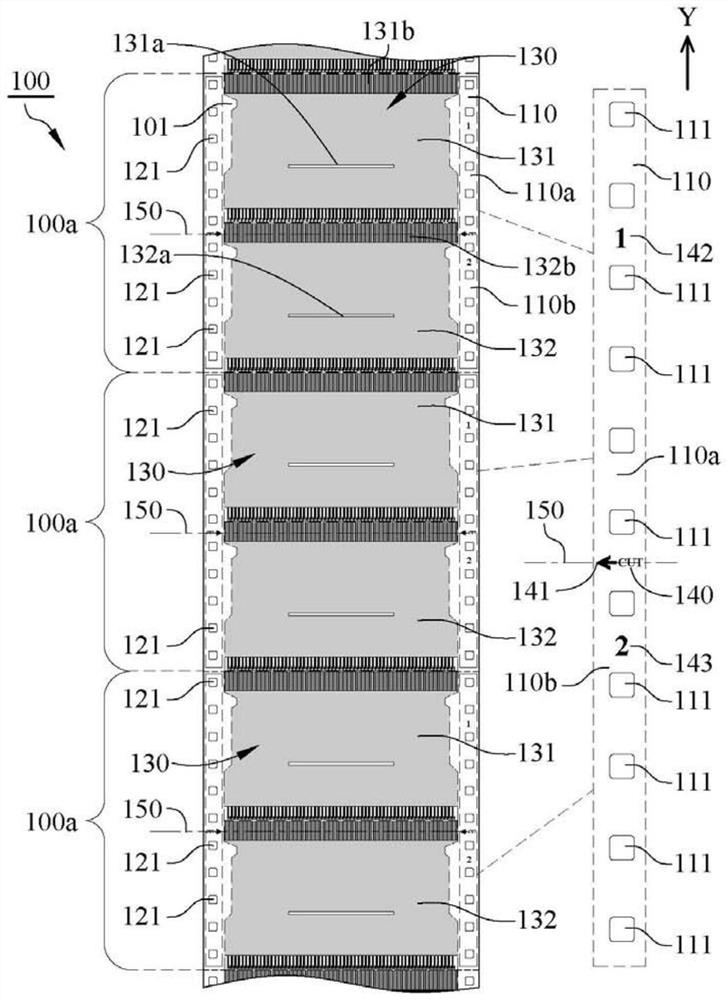

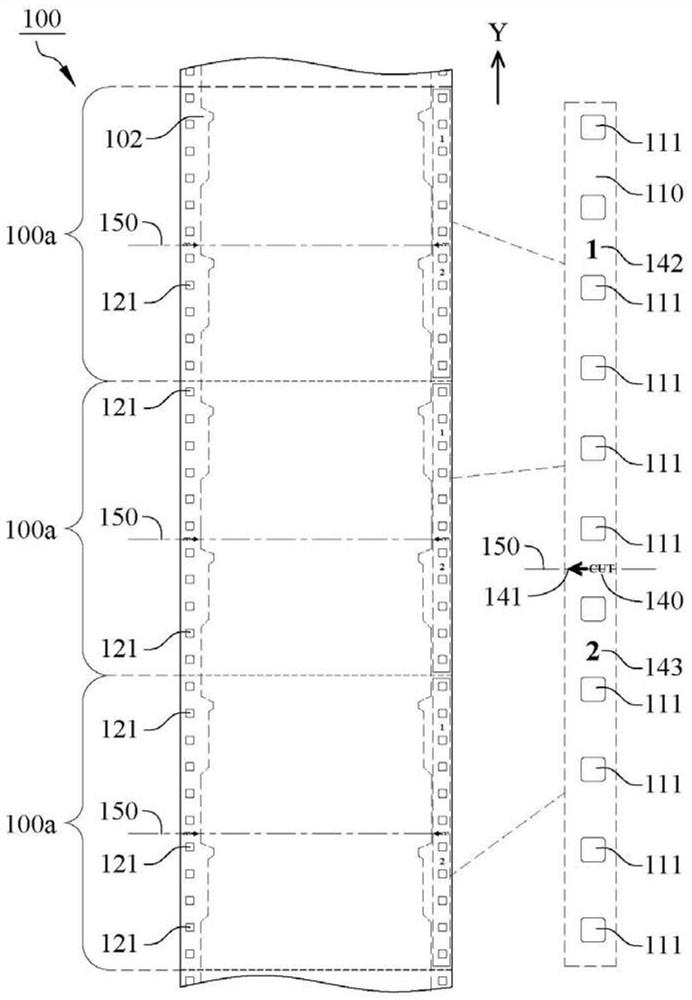

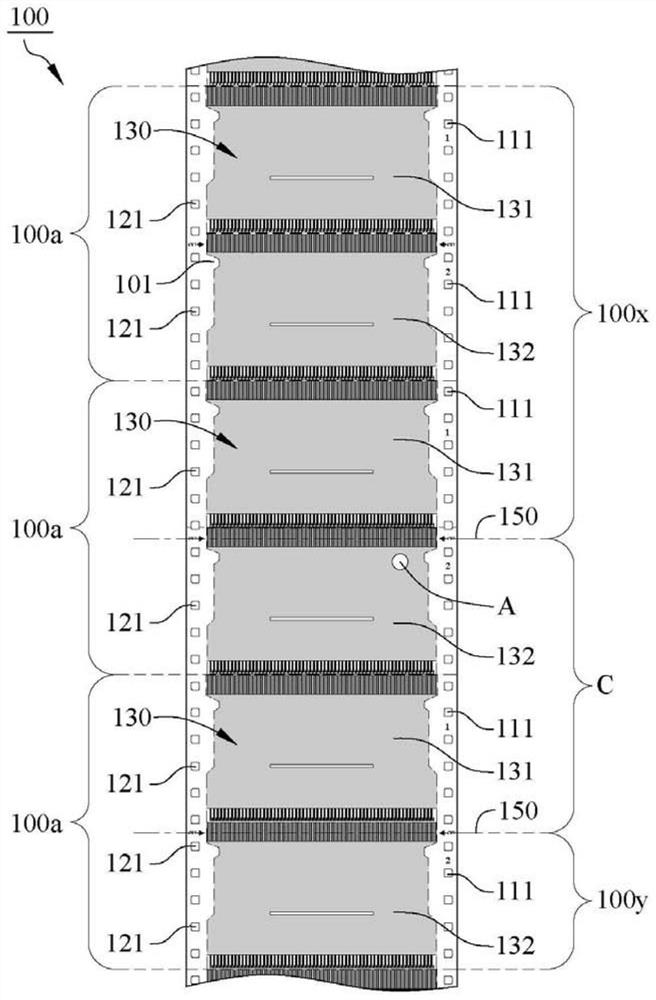

[0044] see figure 1 and figure 2, a circuit board tape 100 of the present invention has a first surface 101 and a second surface 102, the circuit board tape 100 includes a plurality of substrate units 100a arranged along the transmission direction Y, each of the substrate units 100a has a first A transmission hole setting area 110, a second transmission hole setting area 120, a circuit layout area 130 and at least one docking mark 140, the first transmission hole setting area 110 has more than three first transmission holes 111 with an odd number, so The first transmission holes 111 are equidistantly arranged on one side of the substrate unit 100a, please refer to figure 1 and figure 2 In the partial enlarged view, in this embodiment, the first transmission hole setting area 110 has 11 first transmission holes 111 for illustration, but it is not limited thereto.

[0045] see figure 1 and figure 2 , the second transmission hole setting area 120 has more than three secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com