Conductive wire frame strip, glue sealing method and glue sealing structure

A technology of lead frame strips and lead frames, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc. It can solve the problems of wasting lead frame bar 1 space, and it is difficult to further increase the output per unit time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, for a detailed description as follows:

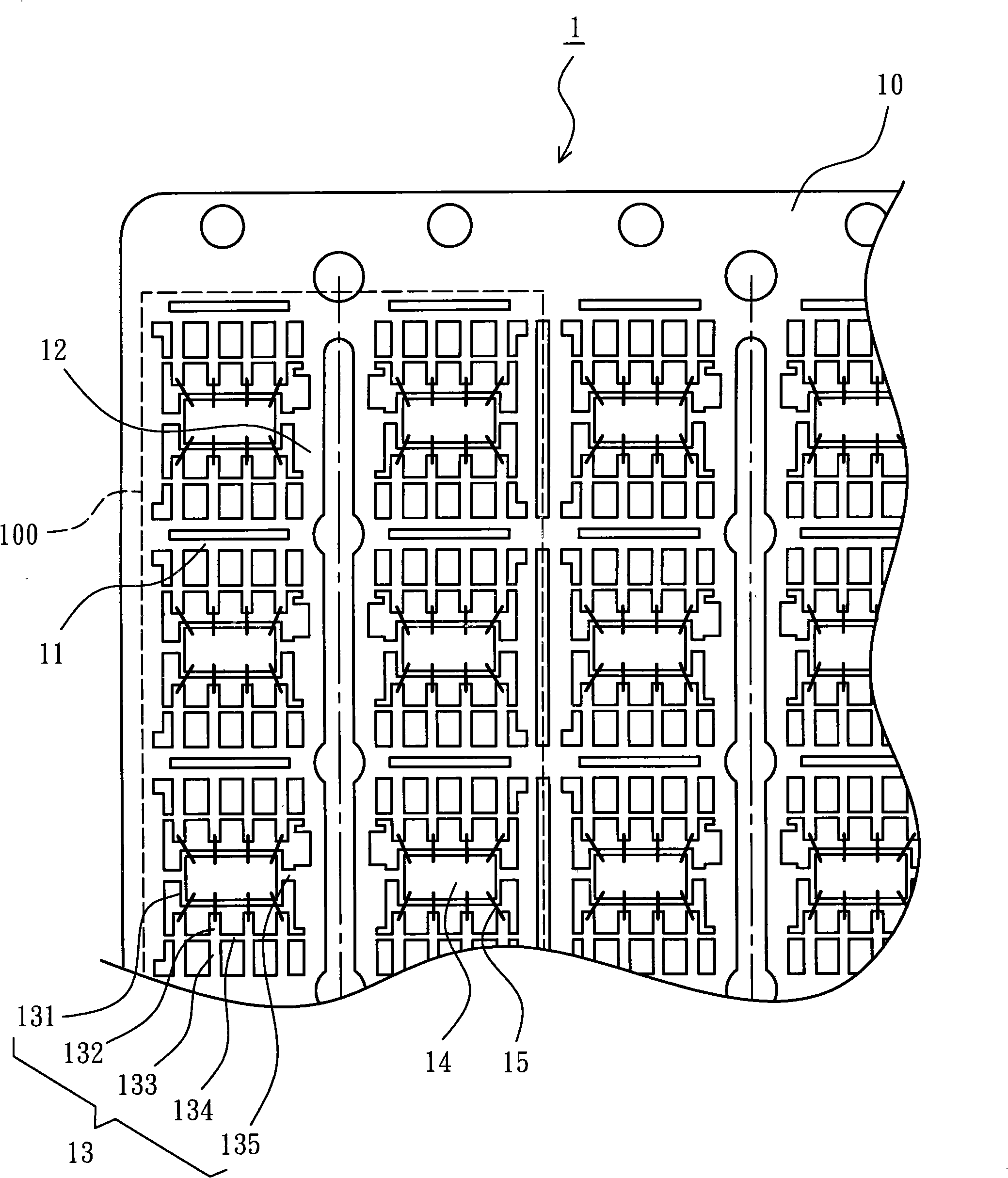

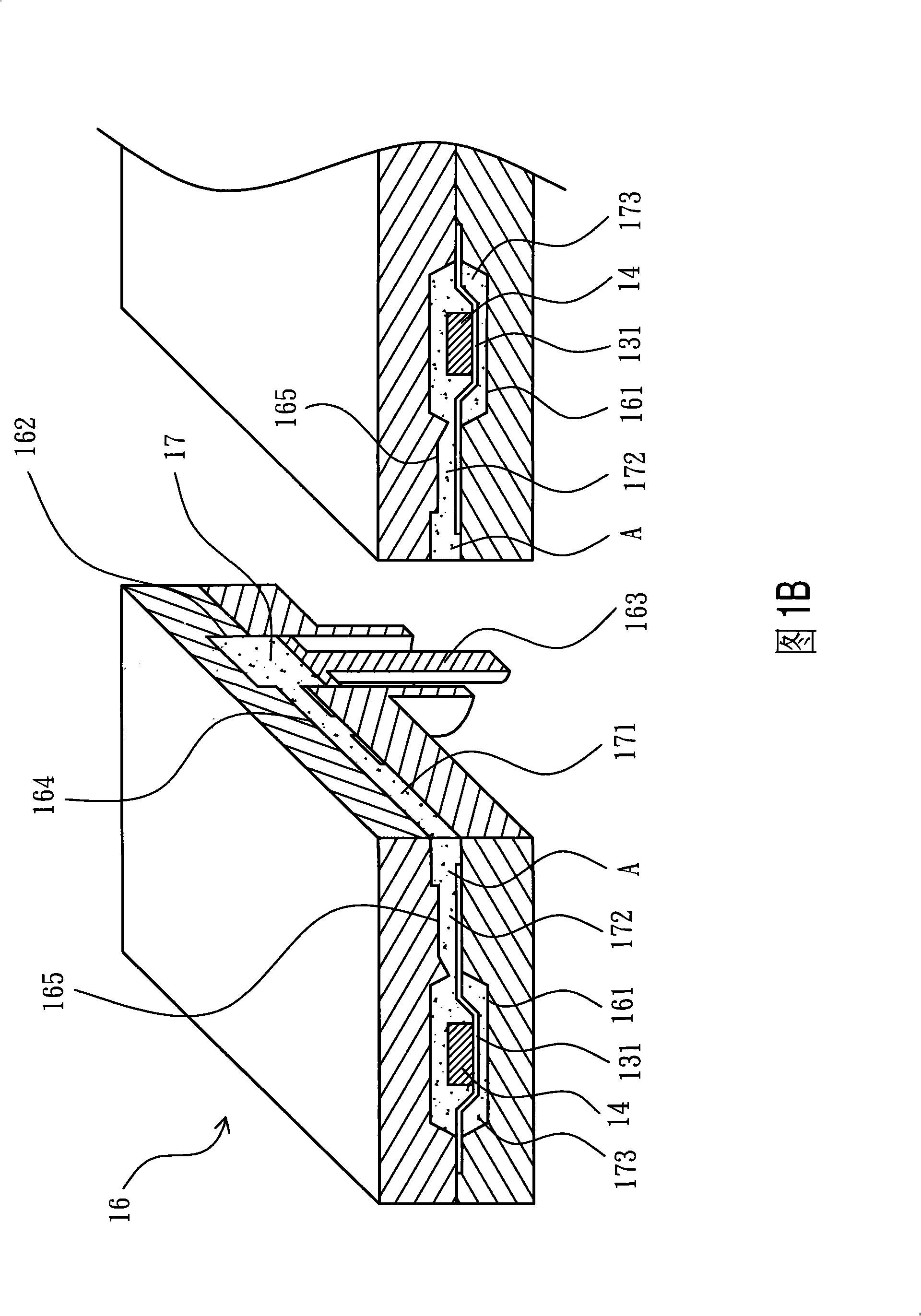

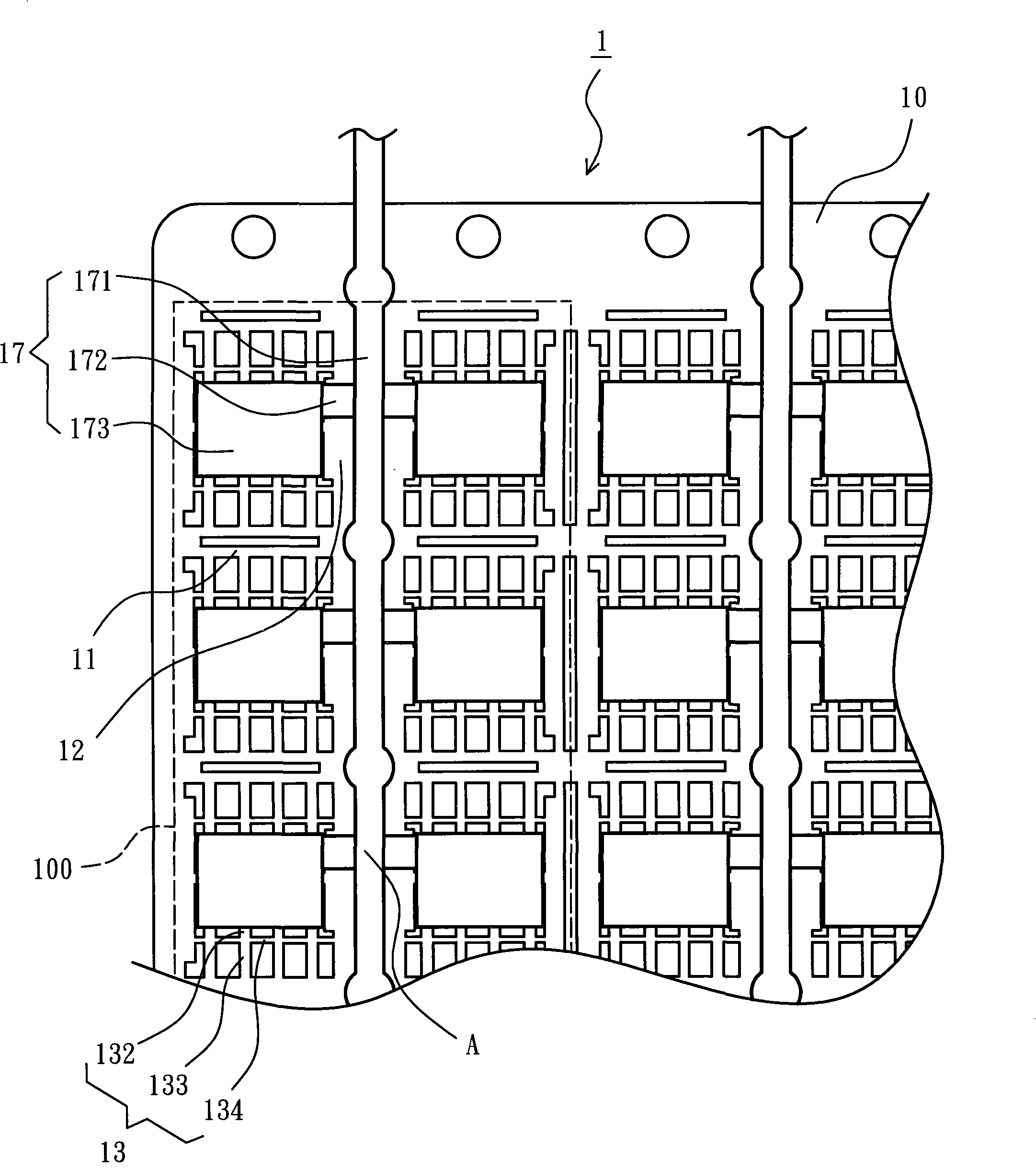

[0031] Please refer to Figure 2A , 2B As shown in and 2C, the lead frame bar and its sealing method and sealing structure of the preferred embodiment of the present invention are mainly used in the manufacture of semiconductor packaging products with double-row lead frames, for example, in the manufacture of small outline packages (SOPs) ), Small Outline J Package (SOJ), Small Outline Transistor Package (SOT), Small Outline Wide Package (SOW), Dual Inline Package (DIP) or other similar package products.

[0032] Please refer to Figure 2A As shown, the lead frame bar 2 of the preferred embodiment of the present invention is a strip-shaped plate body, which is usually made of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com