A kind of molten metal lifting and tilting transfer vehicle and its operation method

A technology of metal melt and operation method, which is applied in the direction of lifting device, metal processing equipment, casting melt container, etc., can solve the problems of inconvenient docking of different height stations, consume a lot of time and rotating space, and save layout space and layout costs, ensuring personal and property safety, and increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

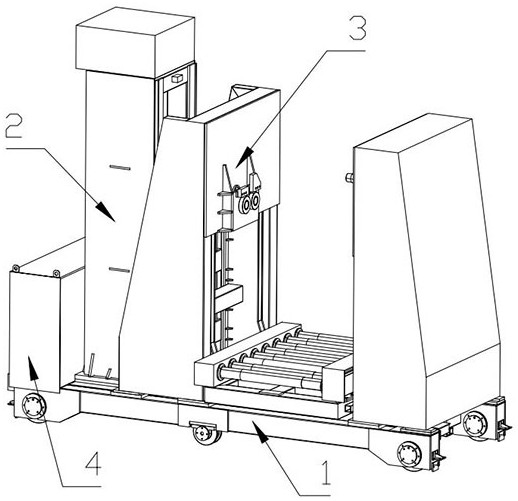

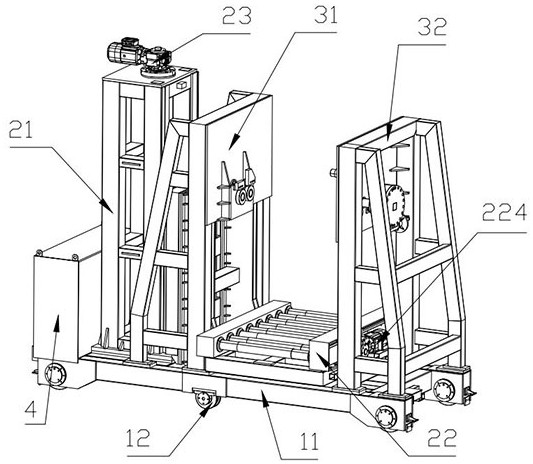

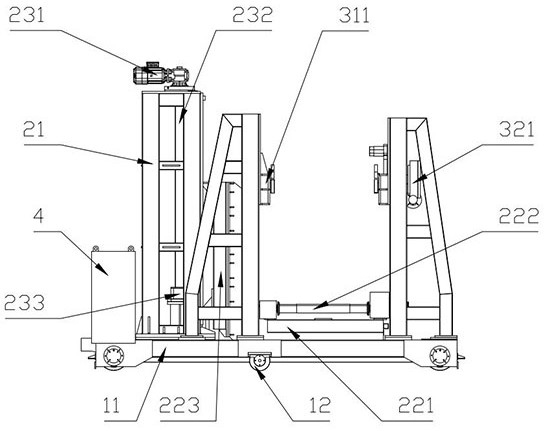

[0042] This embodiment provides a kind of molten metal lifting and tilting transfer vehicle, see figure 1 , comprising a traveling unit 1, a lifting unit 2, a tilting unit 3 and a control unit 4, the upper end of the traveling unit 1 is provided with a lifting unit 2, one side of the lifting unit 2 is provided with a tilting unit 3, and the control unit 4 Located at one end of traveling unit 1.

[0043] In this example, combined with figure 2 , the travel unit 1 includes a vehicle frame 11 and wheels 12, the vehicle frame 11 is arranged horizontally, and the lower ends of both sides are provided with wheels 12, the travel unit 1 also includes a mobile drive machine, and the transmission end of the mobile drive machine It is connected with the wheels 12, and the mobile driving machine is connected with the control unit 4 in communication. The mobile driving machine can drive the wheels 12 to travel along the preset track. The lifting unit 2 and the tilting unit 3 are both loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com