Inkjet nozzle hygiene and print reliability

An inkjet printer, reliable technology, used in printing and other directions, can solve problems such as performance degradation and print quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

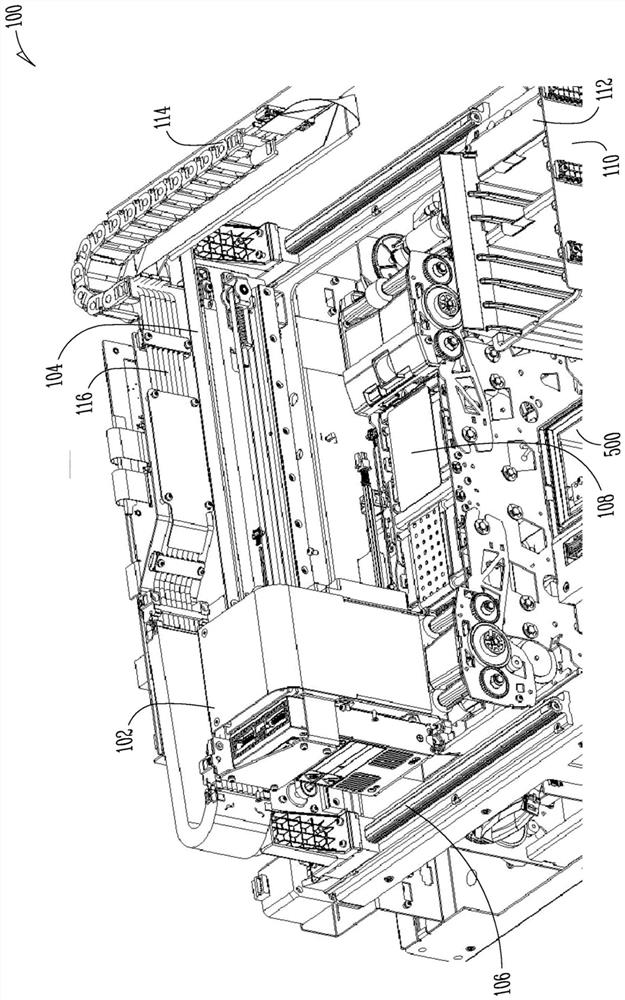

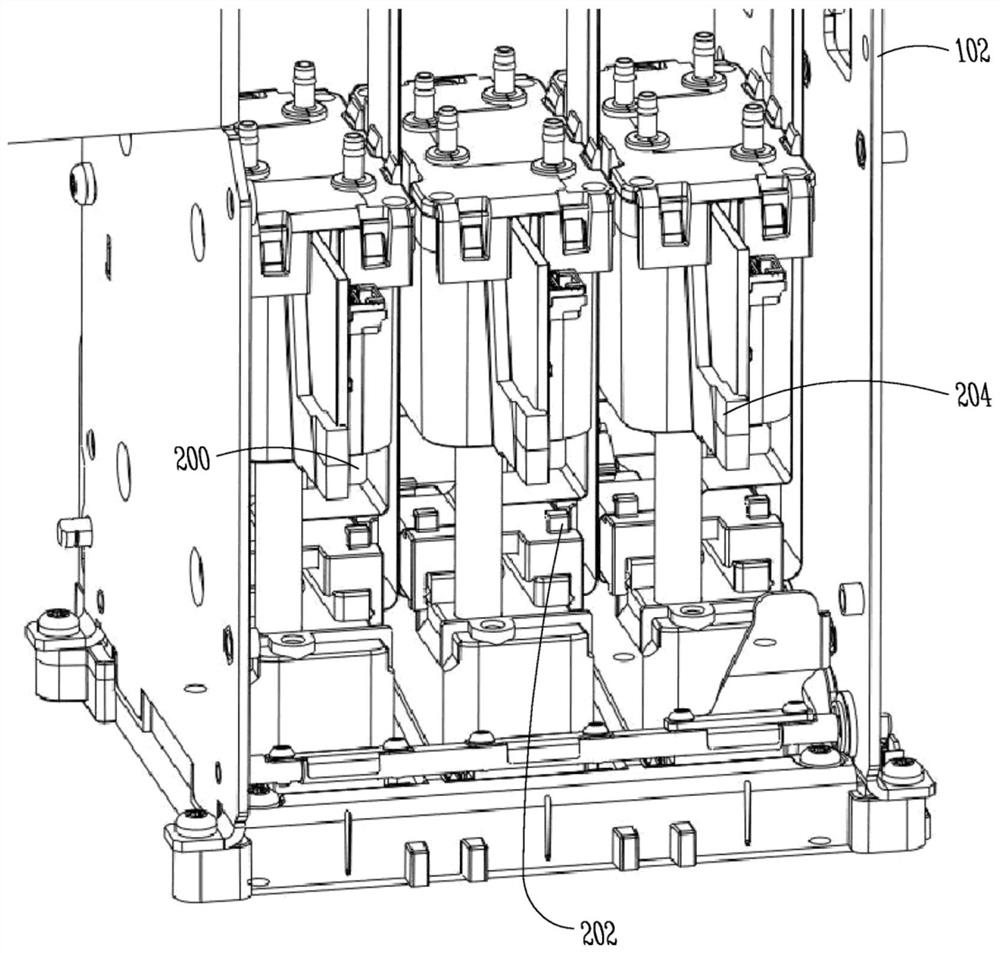

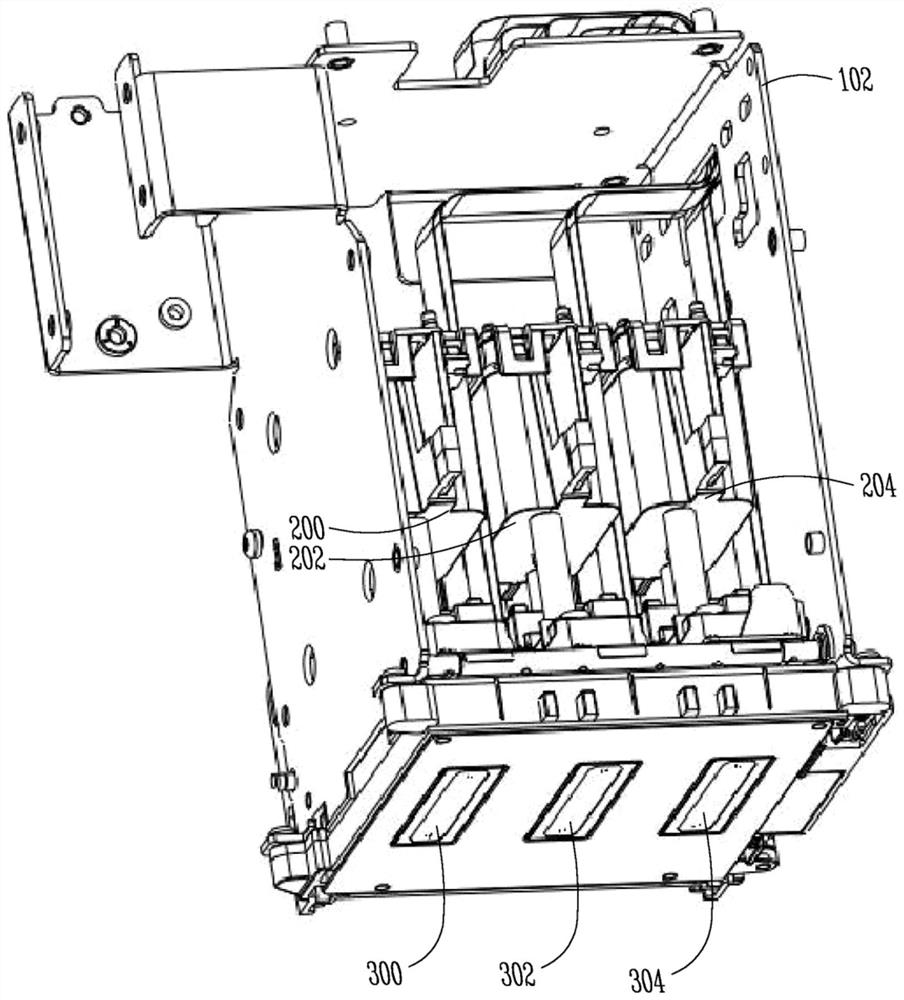

[0024] The use of pigment ink, especially inkjet printing, ink, may be challenging because the pigments in the ink may have relatively large particles. Such inks include, for example, inks comprising titanium dioxide pigments. Large particles can be precipitated from the solution and cause the nozzle (e.g., printhead nozzles, such as piezoelectric printhead nozzles) to block or reduce the opacity of the ink. Further, when some images are printed, some ink jet nozzles in the inkjet nozzle may not be used during printing, which depends, for example, on the size, shape, and / or position of the image to be printed on the substrate. When the nozzle idles the extended period of time, the nozzle may not be kept in the perfusion state, resulting in a poor injection characteristic due to the pigment settlement. In addition, when the same print job (eg, in a plurality of similar substrates, such as the same image or series image in the plastic identification card, each printing of the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com