Variable outlet duct system

A channeling and variable technology, applied in the aviation field, can solve problems such as large environmental impact and heavy helicopter weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

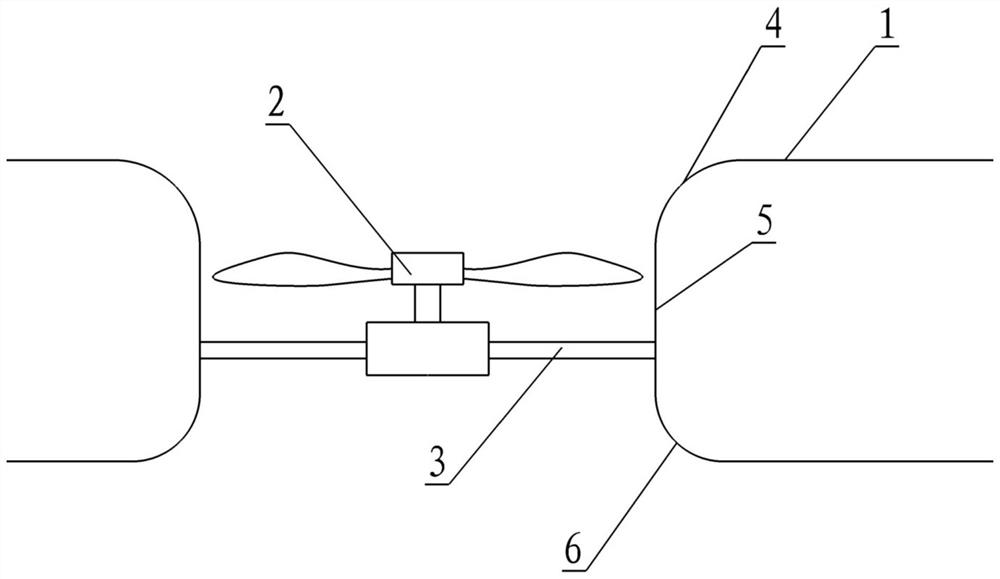

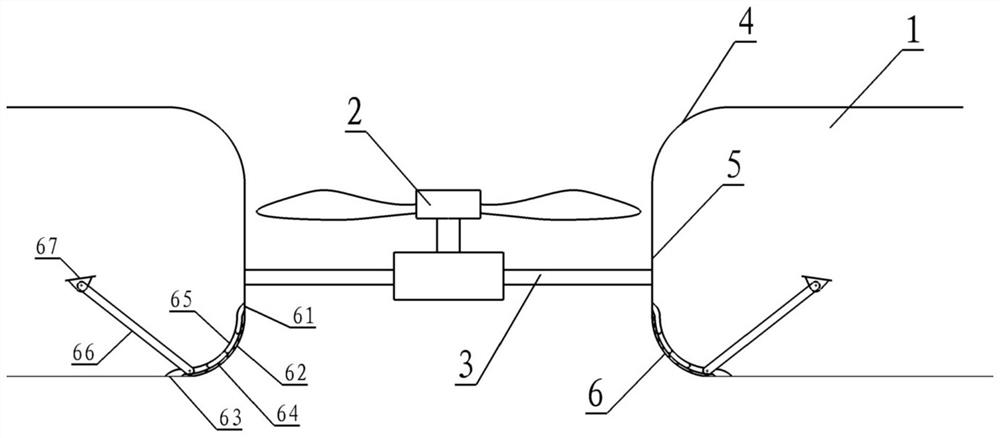

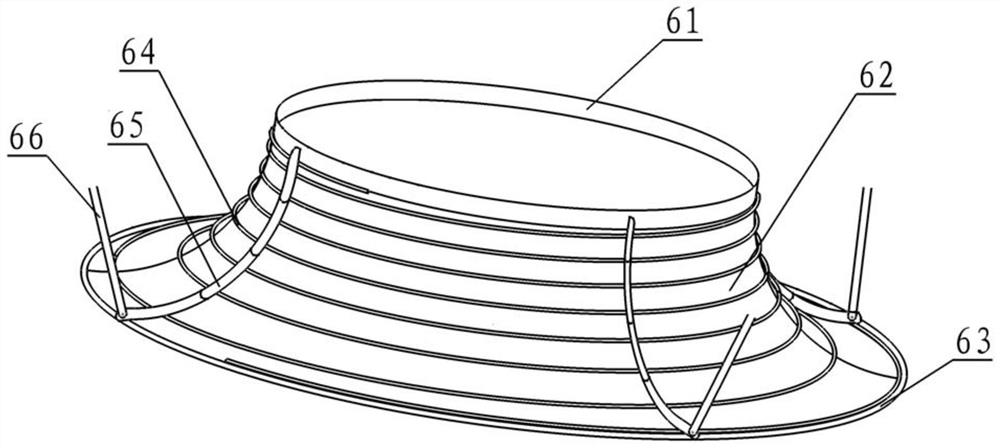

[0030] The variable outlet duct system provided by the present invention will be explained below in conjunction with the accompanying drawings.

[0031] The present invention considers that under the premise of the same lift requirement, the downwash airflow velocity generated by the large-size rotor system is small, which is more friendly to the environment, but the weight of the large-size rotor and duct increases greatly, resulting in excessive weight of the aircraft itself; and light weight The small-sized duct system produces a large downwash airflow, which has a greater impact on the environment, such as more obvious dust effects. Therefore, a duct system with variable outlet diameter is needed here to keep the size and weight small, but the duct outlet can be enlarged during vertical take-off and landing, so that the outlet airflow can be better diffused, thereby increasing the area affected by the duct airflow , reduce the downwash air velocity of the duct, and improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com