Full-automatic vertical spiral car unloader

A technology of vertical screw and unloading machine, which is applied in the field of screw unloading machine, which can solve the problems of reduced power of the whole machine, lower unloading efficiency, and difficult cleaning of fragmented materials, so as to achieve the effect of accelerating unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

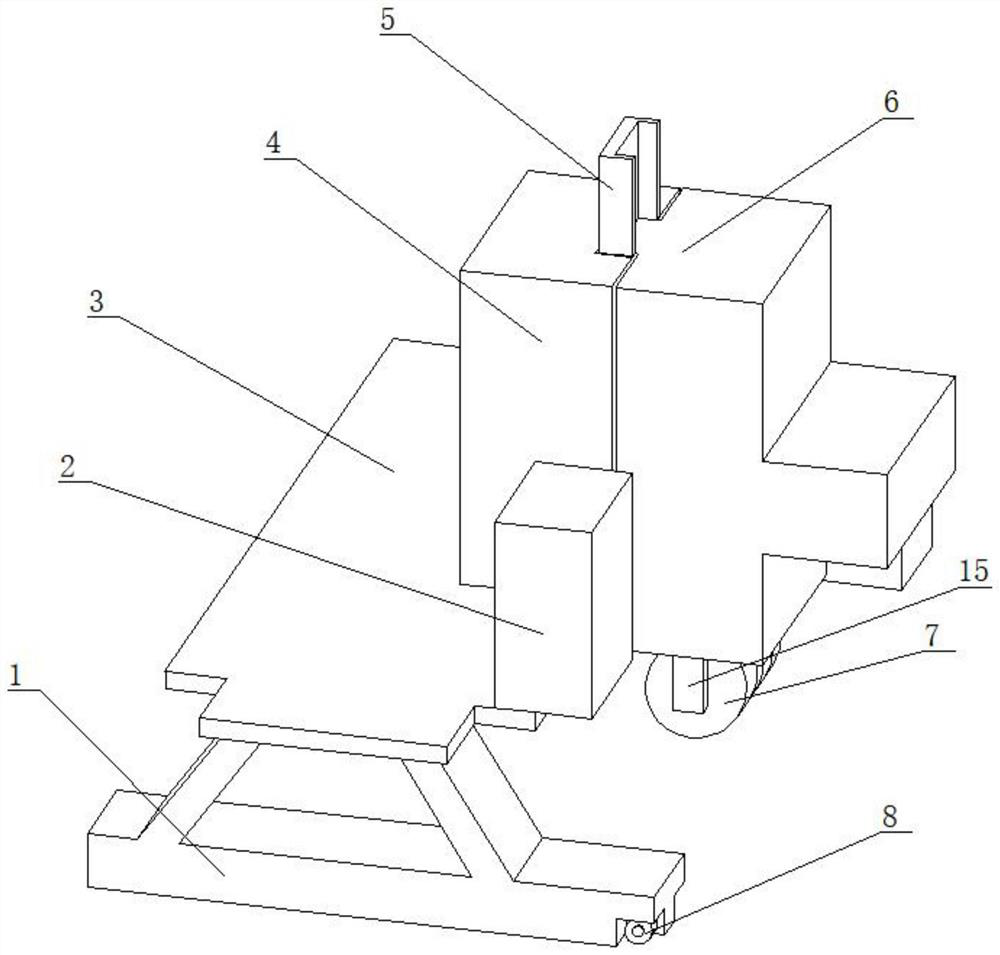

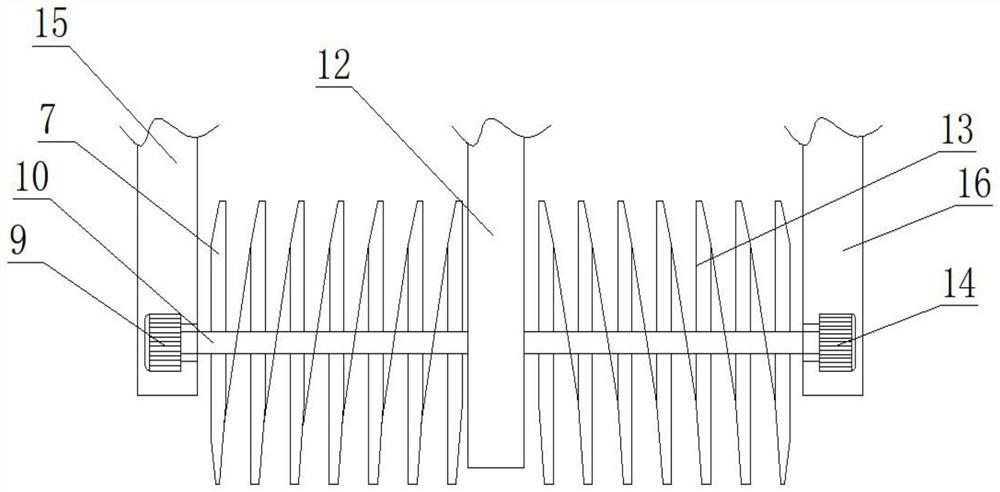

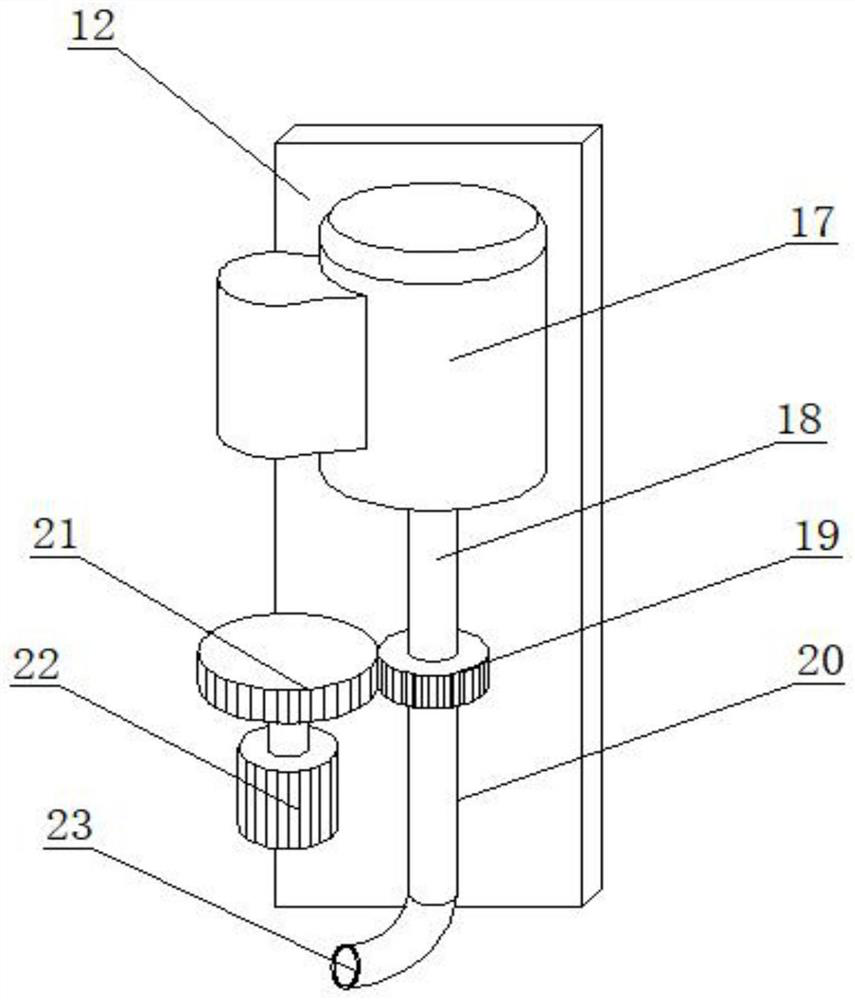

[0034]A fully automatic vertical screw car unloading machine, comprising a plate body 3, a shell 4 is installed in the middle of the top of the plate body 3, and a lifting frame 5 is installed on the right side of the shell 4, and the lifting frame 5 is slidably installed with a cleaning and unloading machine. shell, a stroke sensor 11 is installed between the lifting frame 5 and the cleaning shell, and a cleaning plate 12 is installed on the left and right sides of the bottom end of the cleaning shell, and a movable pneumatic cleaning device is installed on the inner wall of the cleaning plate 12; The travel sensor 11 detects the distance formed to judge the distance between the unloading structure and the bottom of the carriage. When the unloading structure is located at the bottom of the carriage, the pneumatic cleaning device is activated, which can speed up the unloading and at the same time push and unload the fragmented materials at the bottom of the carriage. At the same...

specific Embodiment 2

[0039] A fully automatic vertical screw car unloading machine, comprising a plate body 3, a shell 4 is installed in the middle of the top of the plate body 3, and a lifting frame 5 is installed on the right side of the shell 4, and the lifting frame 5 is slidably installed with a cleaning and unloading machine. shell, a stroke sensor 11 is installed between the lifting frame 5 and the cleaning shell, and a cleaning plate 12 is installed on the left and right sides of the bottom end of the cleaning shell, and a movable pneumatic cleaning device is installed on the inner wall of the cleaning plate 12; The travel sensor 11 detects the distance formed to judge the distance between the unloading structure and the bottom of the carriage. When the unloading structure is located at the bottom of the carriage, the pneumatic cleaning device is activated, which can speed up the unloading and at the same time push and unload the fragmented materials at the bottom of the carriage. At the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com