High-altitude automatic unhooking device for hoisting electric power iron tower

An automatic decoupling and power tower technology, which is applied in the field of power tower installation, can solve problems such as the fall of installation workers and hidden dangers to the safety of installation workers, so as to speed up the beat speed, save connection and disconnection time, and make preparations for hoisting faster and safer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

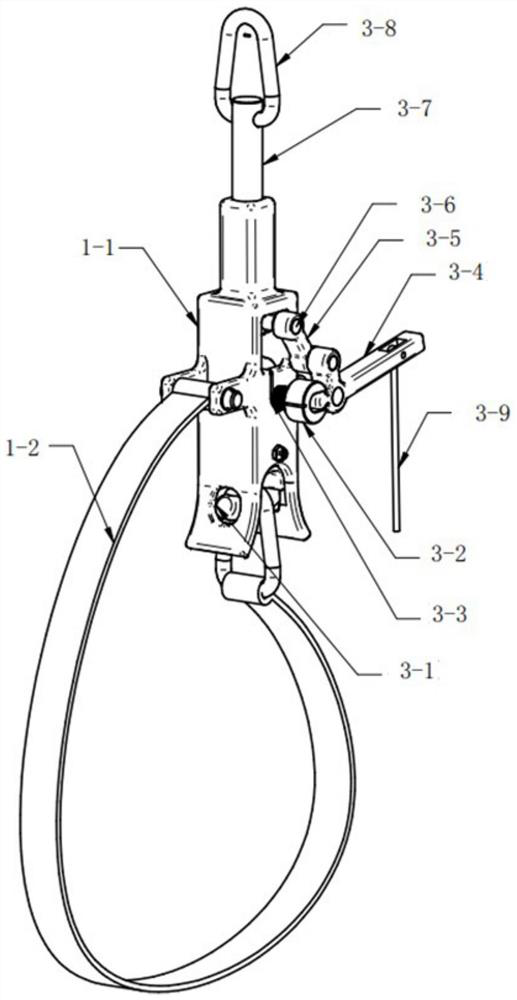

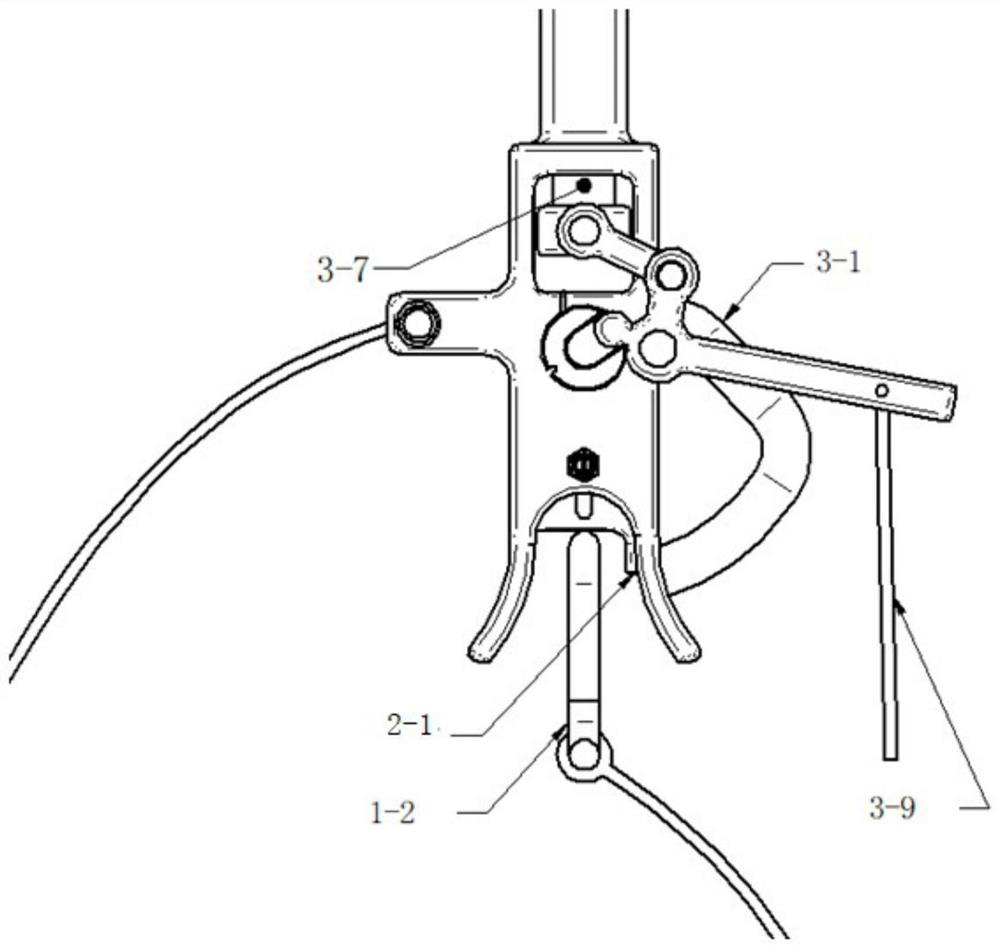

[0029] like Figure 1-Figure 7 As shown, the embodiment of the present invention includes a lifting ring 3-8, a pull rod 3-7, a hook body 1-1, a strap and a lifting ring 1-2, a locking hook 3-1, an unlocking mechanism, and a locking mechanism;

[0030] The lifting ring 3-8 is connected with the pull rod 3-7, and the pull rod 3-7 is connected with the unlocking mechanism; the unlocking mechanism is connected with the lock hook 3-1, which is used to drive the lock hook 3-1 to swing ; The locking mechanism is arranged inside the hook body 1-1 to limit the lock hook 3-1; one end of the sling and the lifting ring 1-2 is connected to the hook body 1-1, and the other end is connected to the hook body 1-1. It is used in conjunction with the lock hook 3-1, and is locked by the lock hook 3-1.

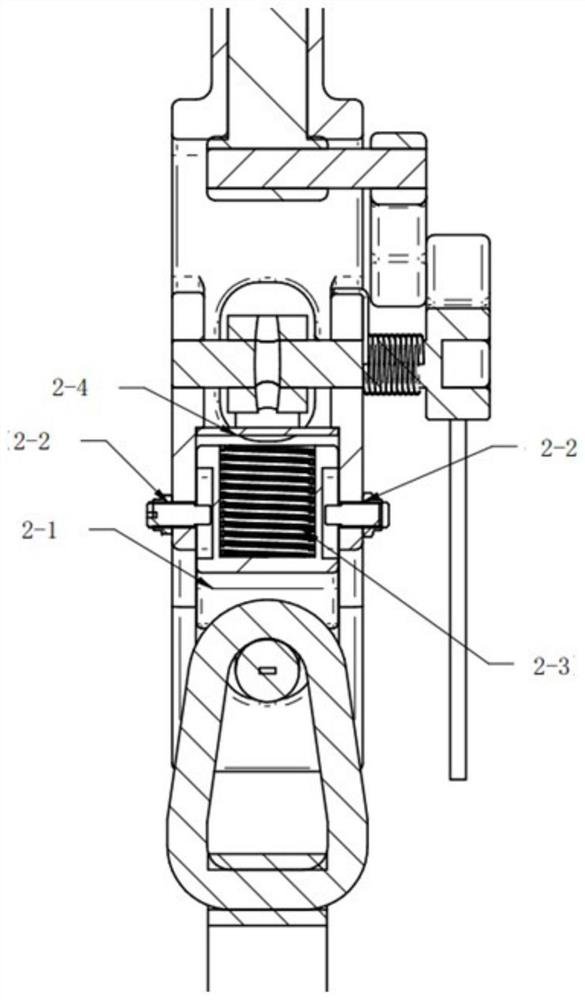

[0031] The locking mechanism includes a deadbolt 2-1, a guide pin 2-2, a deadbolt spring 2-3, and a deadbolt spring baffle 2-4. The locking tongue spring baffle 2-4 is embedded in the hook body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com