Copious cooling liquid linkage filling system and filling method

A cryogenic liquid, automatic technology, used in liquid distribution, conveying or transfer devices, packaging, distribution devices, etc., can solve the problems of air leakage at the joint, the clean room is not suitable for frequent entry and exit, and automatic filling cannot be realized. Labor cost, stable effect of filling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations. In the description of the present invention, it should be noted that unless otherwise specified and Limitation, the terms "installation", "connection" and "connection" should be understood in a broad sense, for example, it can be a fixed connection, it can also be a detachable connection, or an integral connection can be a mechanical connection or an electrical connection; it can be It can be directly connected, or indirectly connected through an intermediary, and can be connected internally between two components.

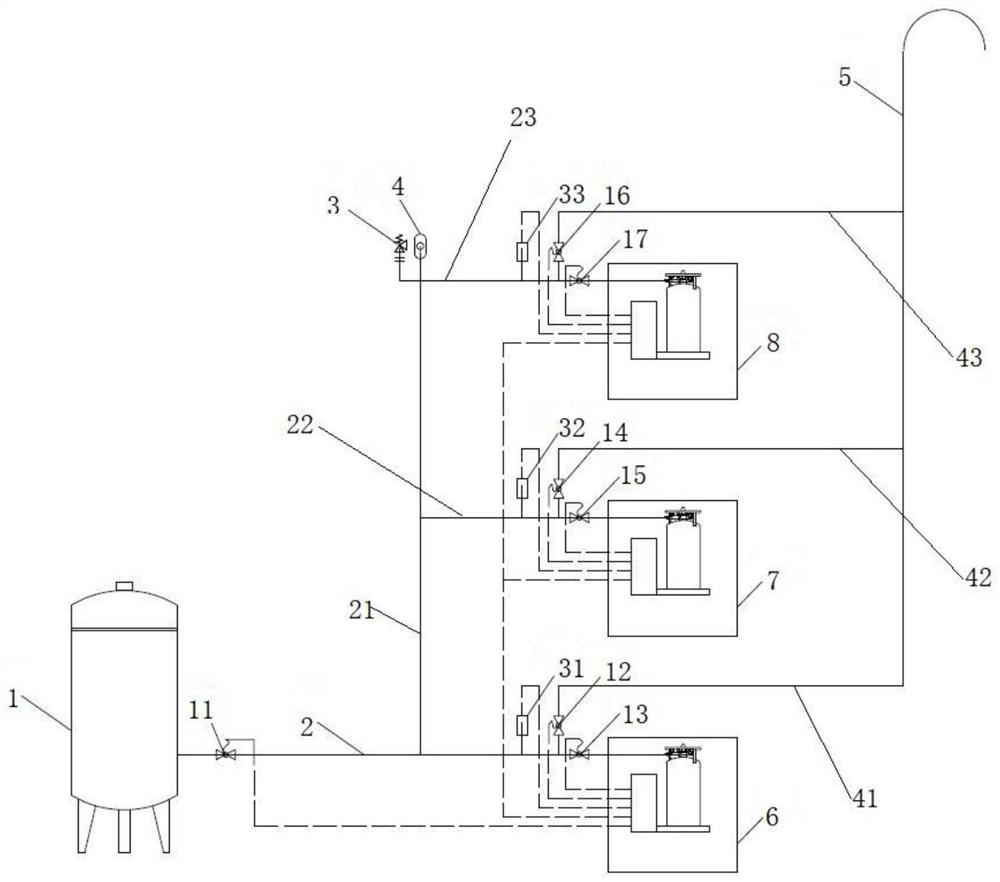

[0020] like figure 1 As shown, a cryogenic liquid linkage filling system includes a storage tank 1, the storage tank 1 is connected to the first weighing platform 6 through the filling pipeline 2, and the first branch is set on the filling pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com