Method for producing double-clutch valve

A dual-clutch and production method technology, applied in the field of casting, can solve problems such as the inability to guarantee the accuracy of the shaft hole of the product, the internal quality of the product, and the air leakage of the product oil passage, so as to achieve stable filling process, reduce development cost and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

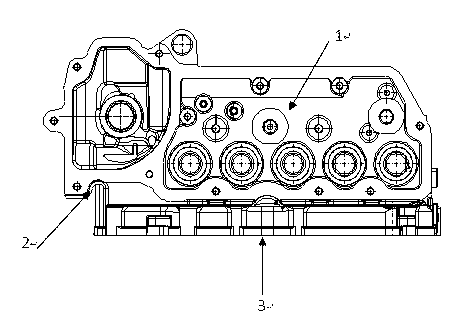

Image

Examples

Embodiment 1

[0025] (1) Ingredients, the weight percentage of each material is as follows: Silicon Si: 8.0%; Iron Fe:: 1.3%; Copper Cu: 2.0%; Manganese Mn:: 0.55%; Magnesium Mg: 0.05%; Zinc Zn:: 1.2% ; Titanium Ti:: 0.25%; Nickel Ni: 0.55%; Tin Sn:: 0.25%; Lead Pb:: 0.35%; 140Mpa, minimum elongation: 1%

[0026] (2) Adjust the cooling water pressure to 2Mpa, and the hydraulic oil pipe pressure to 6Mpa, and connect the mold automatic temperature control device (temperature sensor);

[0027] (3) Heat the melting furnace to 600°C, add the materials described in step (1) into the furnace, continue heating, and when the temperature of the materials rises to 720°C, add Huayu powdered non-toxic refining with an amount of 0.1% of the materials Use a bell jar to press the refining agent into the middle of the material liquid and stir it in a circle for 5 minutes, use argon gas with a purity of 99.99% for degassing operation for 3 minutes, then remove the slag and stand still for 10 minutes to prep...

Embodiment 2

[0032] (1) Ingredients, each material is as follows by weight percentage: Silicon Si: 11.0%; Iron Fe:: 1.0%; Copper Cu: 4.0%; Manganese Mn:: 0.45%; Magnesium Mg: 0.55%; Zinc Zn:: 1.0% ; Titanium Ti:: 0.2%; Nickel Ni: 0.5%; Tin Sn:: 0.15%; Lead Pb:: 0.:2 5%; Tensile strength: 250Mpa, yield strength: 160Mpa, minimum elongation: 0.9%;

[0033] (2) Adjust the cooling water pressure to 6Mpa, and the hydraulic oil pipe pressure to 12Mpa, and connect the mold automatic temperature control device (temperature sensor);

[0034] (3) Heat the smelting furnace to 650°C, add the materials described in step (1) into the furnace, continue heating, and when the temperature of the materials rises to 710°C, add Huayu powdered non-toxic refining with an amount of 0.8% of the materials agent, use a bell jar to press the refining agent into the middle of the material liquid and perform circular stirring for 5 minutes, use argon gas with a purity of 99.99% for degassing operation for 15 minutes, t...

Embodiment 3

[0039] (1) Ingredients, each material is as follows by weight percentage: silicon Si: 10.0%; iron Fe:: 1.2%; copper Cu: 3.0%; manganese Mn: 0.35%; magnesium Mg: 0.30%; zinc Zn: 0.8%; titanium Ti: 0.02%; Nickel Ni: 0.36%; Tin Sn: 0.18%; Lead Pb: 0.30%; 0.8%

[0040] (2) Adjust the cooling water pressure to 4Mpa, and the hydraulic oil pipe pressure to 8Mpa, and connect the mold automatic temperature control device (temperature sensor device);

[0041](3) Heat the smelting furnace to 700°C, add the material described in step (1) into the furnace, continue heating, and when the temperature of the material rises to 730°C, add Huayu powdered non-toxic refining with an amount of 0.4% of the material Use a bell jar to press the refining agent into the middle of the material liquid for 10 minutes of circular stirring, use argon gas with a purity of 99.99% for degassing operation for 8 minutes, then remove the slag and stand still for 12 minutes to prepare for die-casting;

[0042] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com