Fuse wire inserting device for firework production

A fire wire and fireworks technology, which is applied in the field of fire wire insertion devices for firework production, can solve the problems of easily overwhelming fingers, potential safety hazards, and ununiform positions of the insertion leads of firework paper tubes, avoiding manual positioning and reducing The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

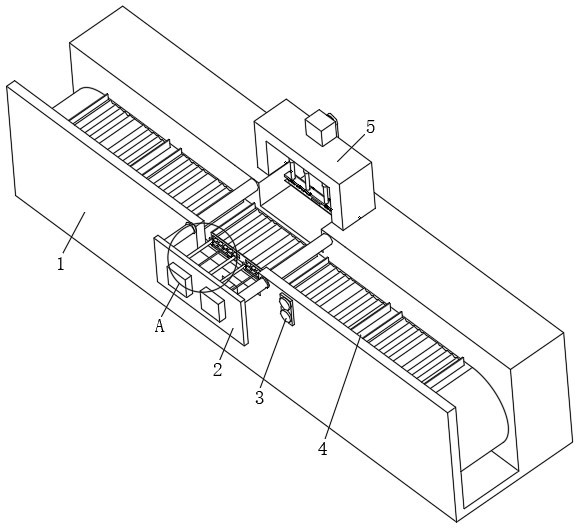

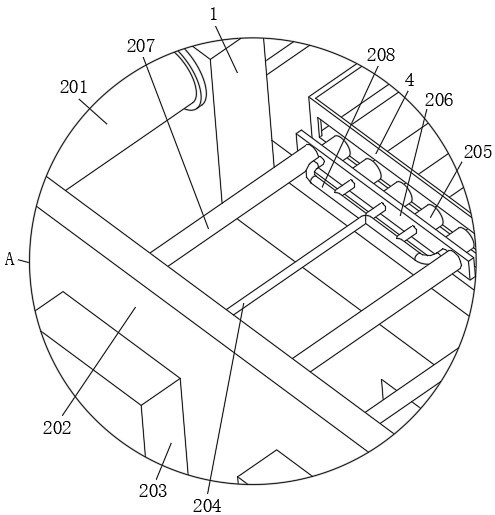

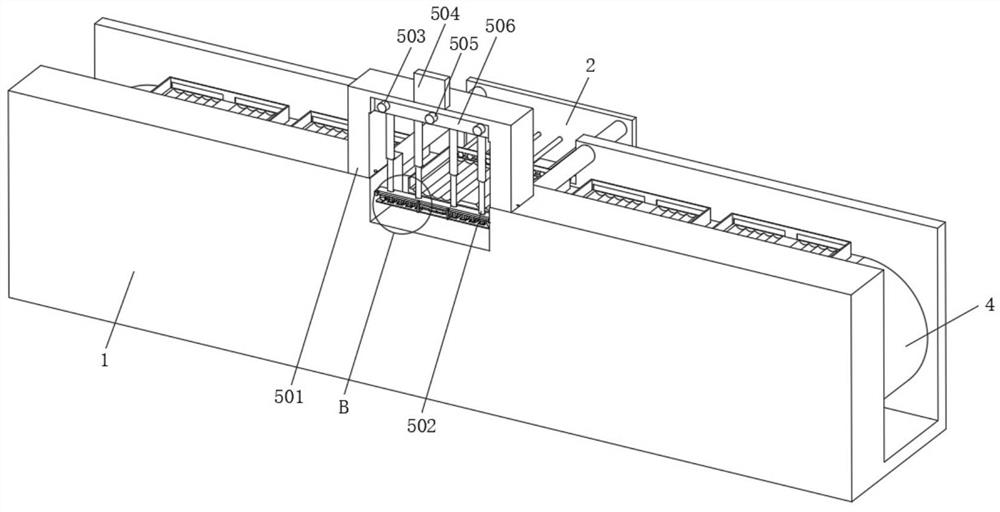

[0022] combined with Figure 1~7 The fuse inserting device for fireworks production includes a frame body 1, a conveying mechanism 4 is installed in the frame body 1, grooves are respectively provided on both sides of the frame body 1, and the two grooves Corresponding to the position, a pushing mechanism 2 is installed on the frame body 1, the pushing end of the pushing mechanism 2 is located in the groove, and the driving end of the conveying mechanism 4 is installed on the pushing end of the pushing mechanism 2, through The pushing mechanism 2 controls the conveying mechanism 4 to move, so that the moving frequency of the conveying mechanism 4 is the same as that of the pushing mechanism 2, and the position of the pushing end of the pushing mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com