Production method of shaft sleeve with boss

A production method and shaft sleeve technology, applied in the field of powder metallurgy, can solve problems such as low production efficiency and positioning, and achieve the effects of improving production efficiency and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples.

[0022] The embodiment of the present invention provides a production method of a bushing with a boss, including the following steps:

[0023] S1. Using the forming process to obtain the shaft sleeve, such as figure 1 shown;

[0024] S2. Using a sintering process to sinter the shaft sleeve;

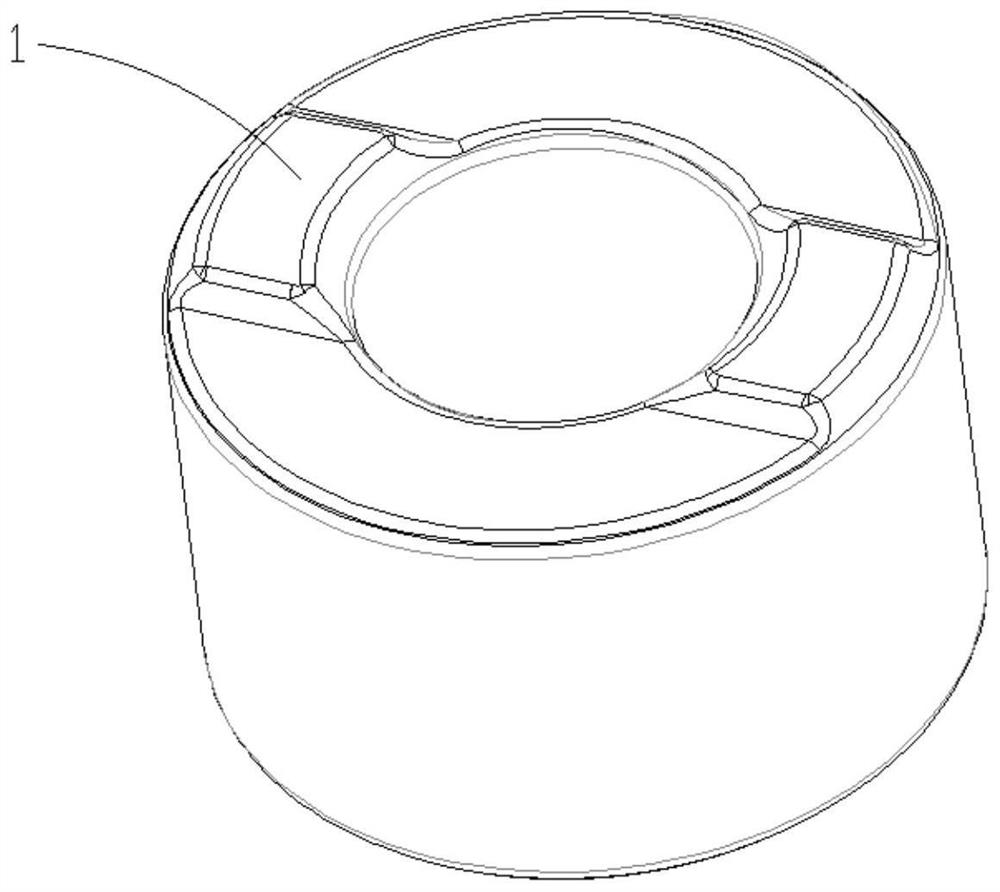

[0025] S3. Use the shaping process to shape the surface of the shaft sleeve, such as figure 2 shown;

[0026] In the forming process, the surface of the shaft sleeve is smooth without bosses;

[0027] In the shaping process, the surface of the boss is finished by using a mold to obtain a bushing with a boss structure on the surface, which is a boss bushing.

[0028]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com