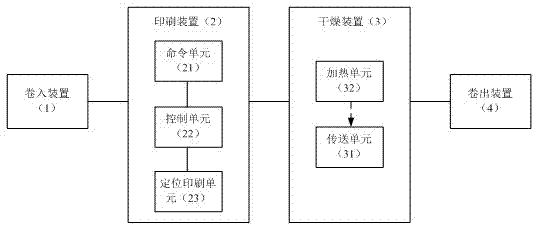

Device and method for continuously printing and drying flexible circuit boards

A technology of flexible circuit boards and drying devices, which is applied in printing devices, printing post-processing, general parts of printing machinery, etc., can solve problems such as low production efficiency, ink defects, printing offset, etc., to improve efficiency, ink Uniform thickness, improved speed and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

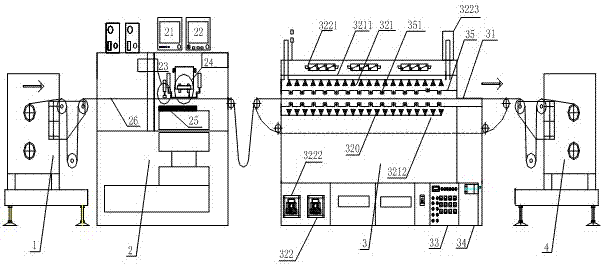

[0034] First, the flexible circuit board to be printed is fed into the conveying unit 26 of the printing device 2 in parallel through the winding device 1; at the same time, the adsorption unit 25 adsorbs the flexible circuit board, and the adsorption unit 25 is used to absorb the dust of the flexible circuit board, The finishing unit 24 is used to level the flexible circuit board, the command unit, the control unit and the positioning printing unit, the command unit 21 is used to display the position of the flexible circuit board, the control unit 22 is used to control the position, the positioning printing unit 23 adjusts the position of the flexible circuit board; Next, a roll of the flexible printed circuit board to be dried by the ink is fed into the transfer unit 31 of the drying device 3 in parallel through the transfer unit 26 of the printing device 2; at the same time, the heating unit 32 of the drying device 3 dries the ink on the flexible printed circuit board.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com