Vibration performance simulation test device of lubricating oil tank-mounting structure

A technology of installation structure and simulation test, applied in the field of aero-engine, can solve the problems of no reference or application of the structure design scheme of the simulation test device, and no more complete research method, so as to achieve simple installation principle and process, light weight and reliable connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

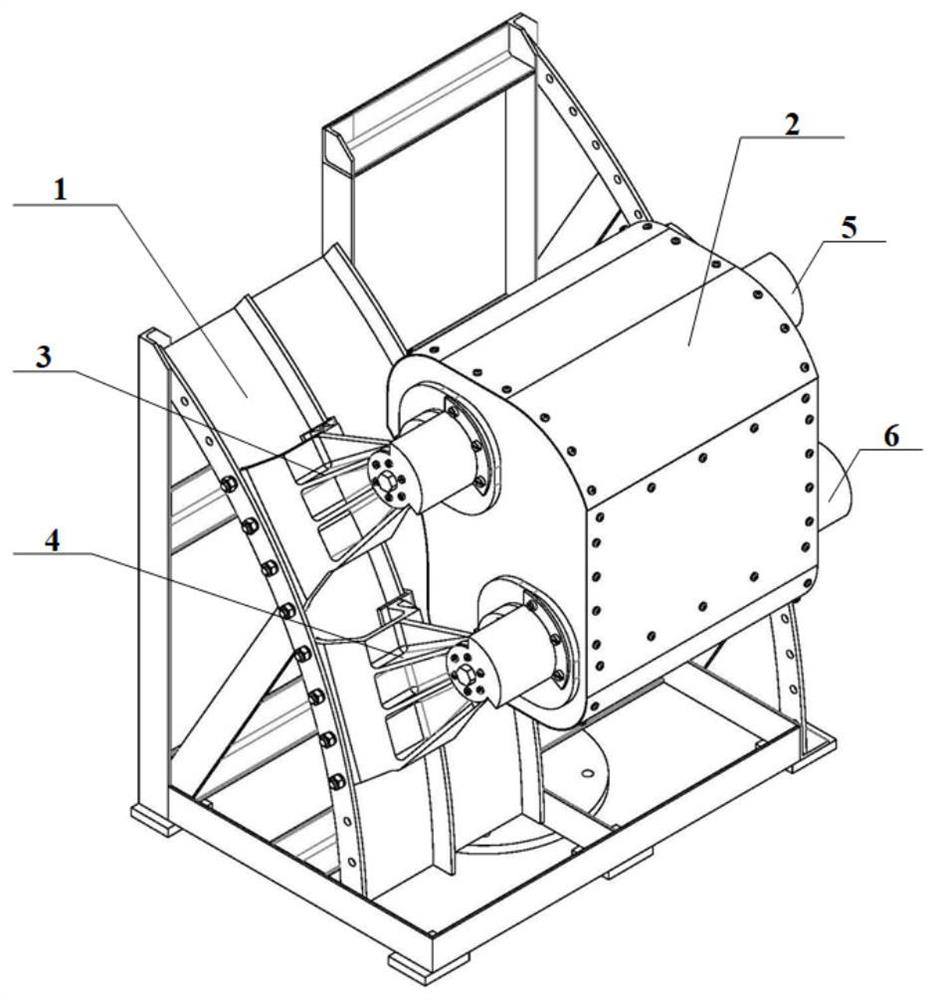

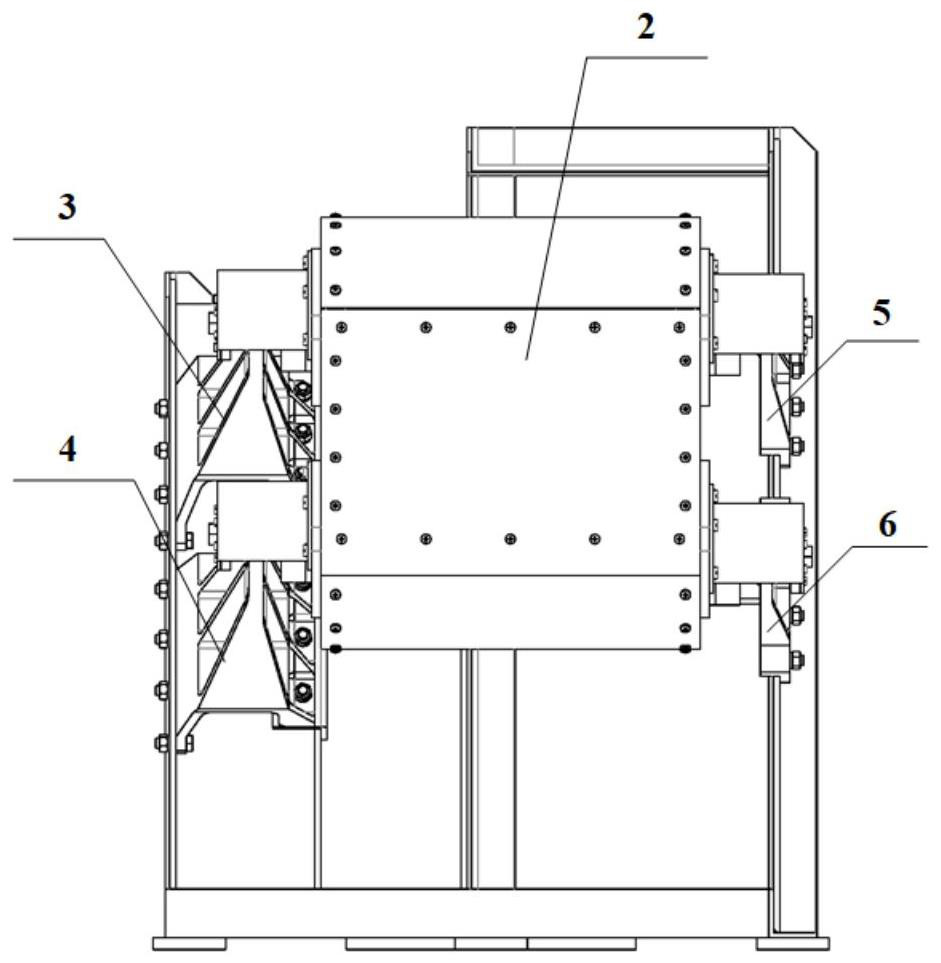

[0028] A specific embodiment of the vibration performance simulation test device of the mounting structure will be described in conjunction with the drawings.

[0029] Taking the four-support system as an example, before the vibration test is carried out, the vibration performance simulation test device of a la carteracery-mounting structure is installed, and the installation process is performed according to the following procedure:

[0030] 1) First, mount the support 3 on the upper left side, the upper left side mounting the mount 4, the upper right side mounting the support 5, and the upper right side mounting support 6 is sequentially fixed to the mounting edge of the side surface of the casing base 1 by the bolt.

[0031] 2) Second, the upper left anchor contact, the upper right side anchor contact, the lower left side anchor contact, and the upper right side anchor contact, respectively, and the installation of the structural assembly are mounted. The installation structure...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap