Transformer protection device with monitoring function

A transformer protection and function technology, applied in transformer/inductor cooling, transformer/inductor components, fire alarms that rely on smoke/gas effect, etc., can solve problems such as affecting service life and lack of increasing transformer heat dissipation, To achieve the effect of increasing the rate of fire extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

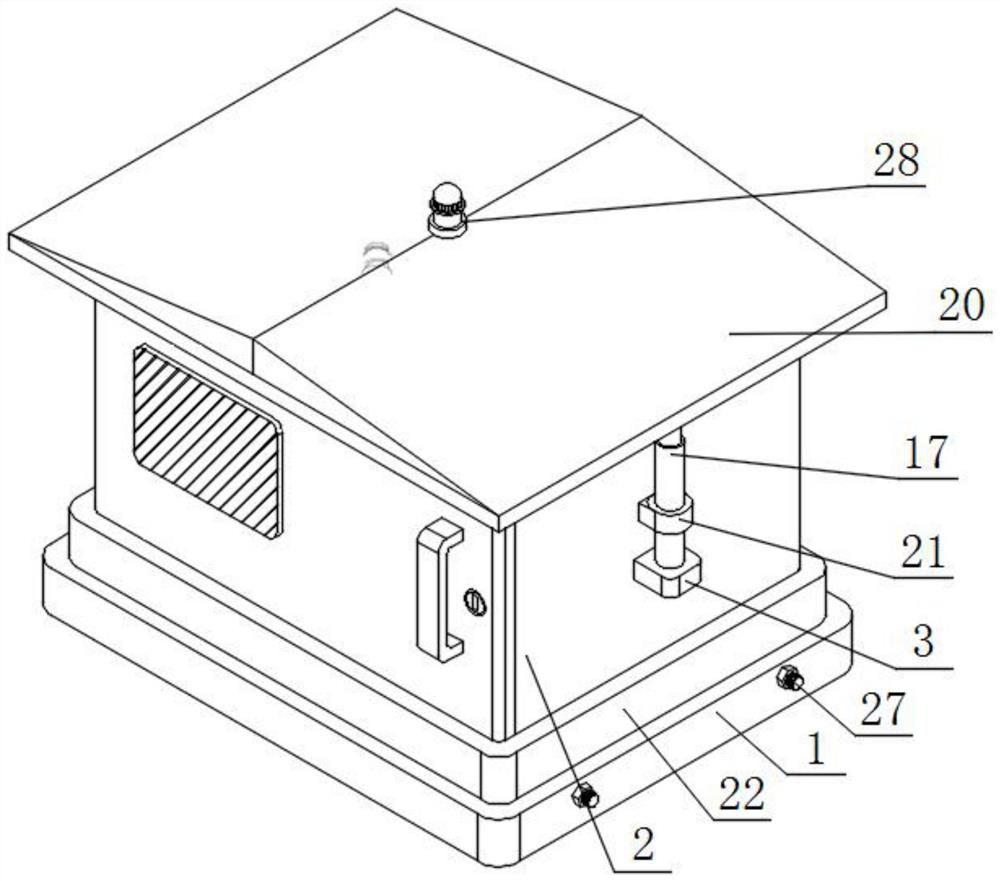

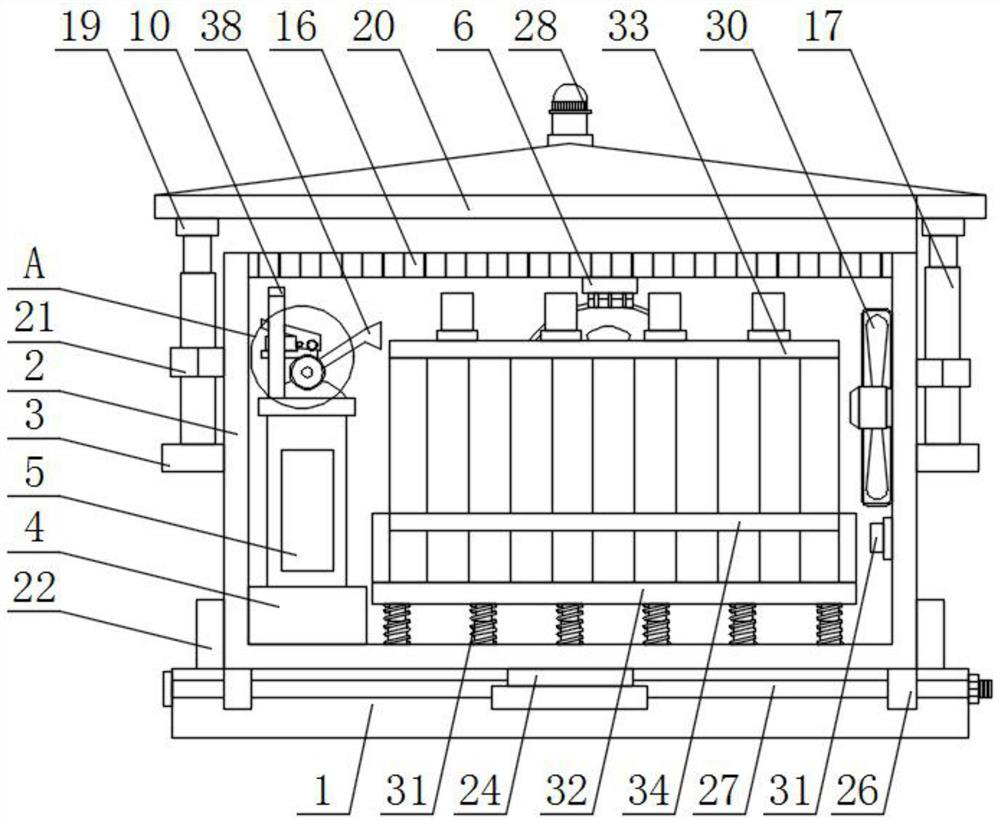

[0043] Such as figure 2 , image 3 , Figure 4 , Figure 6 and Figure 7 As shown, a transformer protection device with monitoring function includes a base 1, a protection box 2, a fixed plate 3, a long body frame 4 and a dry powder fire extinguisher bottle body 5, and a protection box 2 is installed on the top of the base 1, and the protection box 2 Both sides of the outer wall are equipped with fixed plates 3;

[0044] Specifically, the base 1 and the ground can be in a fixed connection state, which can provide a space for the protection box 2 to avoid direct contact between the protection box 2 and the ground, and at the same time facilitate the gravity sensor 24 to monitor the comprehensive gravity of the protection box 2. 2. Add a certain degree of protection for the transformer body 33 to avoid more interference from the outside world during its operation. The fixed plate 3 provides a place for the electric lifting rod 17 to be placed.

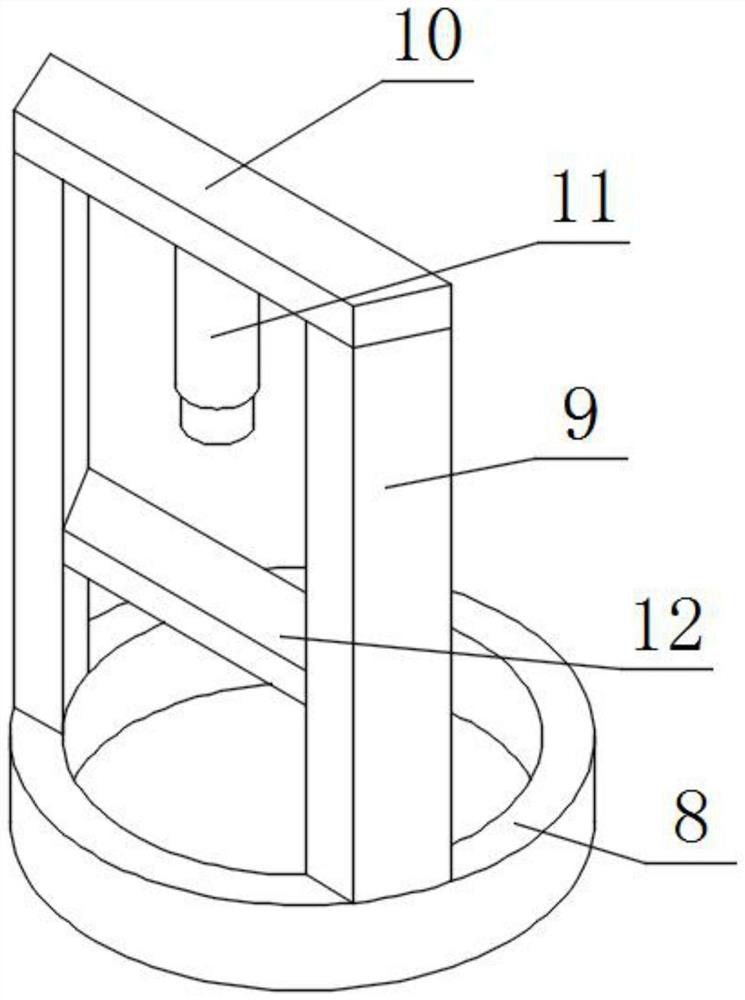

[0045] The bottom wall of t...

Embodiment 2

[0054] Such as figure 1 , figure 2 and Figure 5 As shown, the top of the protection box 2 is provided with multiple groups of evenly arranged through grooves 16, and the tops of the two groups of fixed plates 3 are equipped with electric lifting rods 17, and the tops of the electric lifting rods 17 are equipped with threaded discs 18, and the tops of the threaded discs 18 The outer surface is equipped with threaded cylinder 19, the top of two groups of threaded cylinders 19 is equipped with inclined top cover 20, the outer surface of electric lifting rod 17 is equipped with limiting cylinder 21, and the outer wall of one side of limiting cylinder 21 is attached to the outer wall of protection box 2 combine.

[0055] Specifically, when the top of the through groove 16 is not blocked, it can facilitate the discharge of hot air inside the protection box 2. When the electric lifting rod 17, the inclined top cover 20 and the protection box 2 are assembled, the electric lifting ...

Embodiment 3

[0057] Such as figure 2 and Figure 8 As shown, a square frame 22 is installed on the top of the base 1, and a fitting groove 23 is installed on the top of the base 1, and the fitting groove 23 is inside the enclosed space of the square frame 22, and the inner wall of the fitting groove 23 is installed with a gravity For the sensor 24, the top of the base 1 is provided with two groups of grooves 25 arranged side by side, and the grooves 25 are located on both sides of the fitting groove 23, and the bottom of the protective box 2 is equipped with two groups of long strips 26 arranged side by side, and the length The outer wall of the strip 26 fits the inner wall of the groove 25 , and two groups of fastening bolts 27 arranged front and back are installed on the outer wall of one side of the base 1 , and one end of the fastening bolt 27 runs through the inside of the two sets of long strips 26 .

[0058] An alarm 28 is installed on the top of the inclined top cover 20 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com