Wafer supporting seat and process cavity

A support seat and wafer technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve problems such as difficult duplication of circuit components and affecting radio frequency transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which certain exemplary embodiments are shown by way of illustration. However, claimed subject matter may be embodied in many different forms, and thus constructions of covered or claimed subject matter are not limited to any example embodiments disclosed in this specification; the example embodiments are merely illustrations. Likewise, the invention resides in providing a reasonably broad scope for claimed subject matter as claimed or covered.

[0031] The term "in one embodiment" used in this specification does not necessarily refer to the same embodiment, and the use of "in other (some / some) embodiments" in this specification does not necessarily refer to different embodiments. It is intended, for example, that claimed subject matter includes combinations of all or some of the exemplified embodiments.

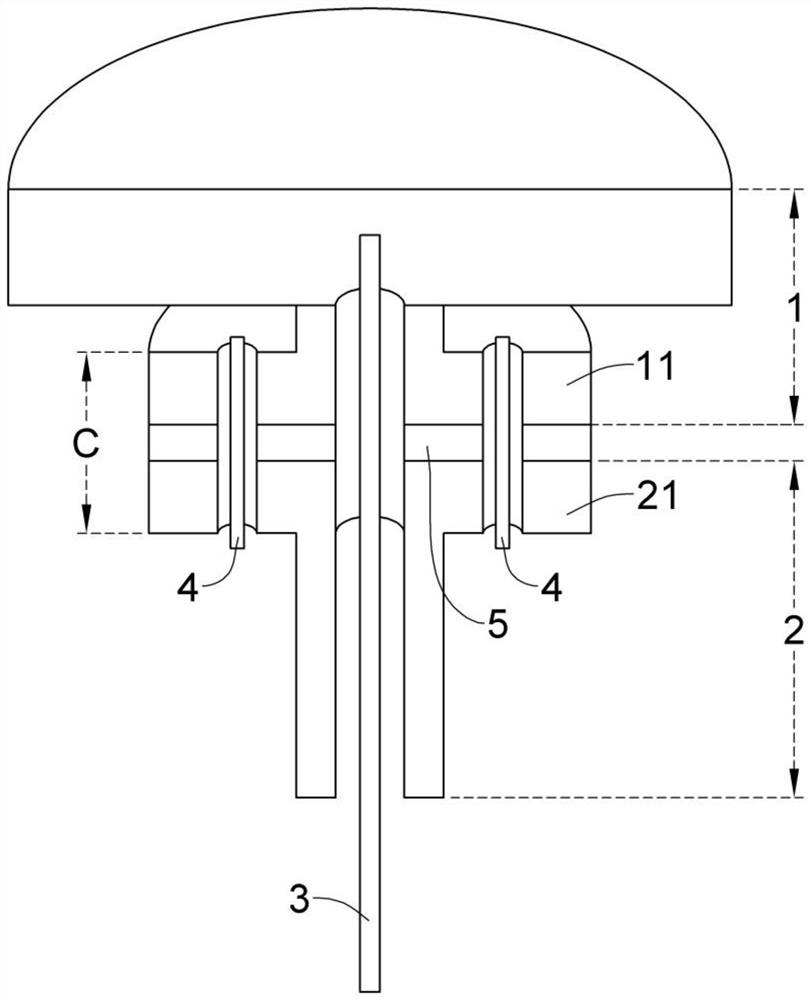

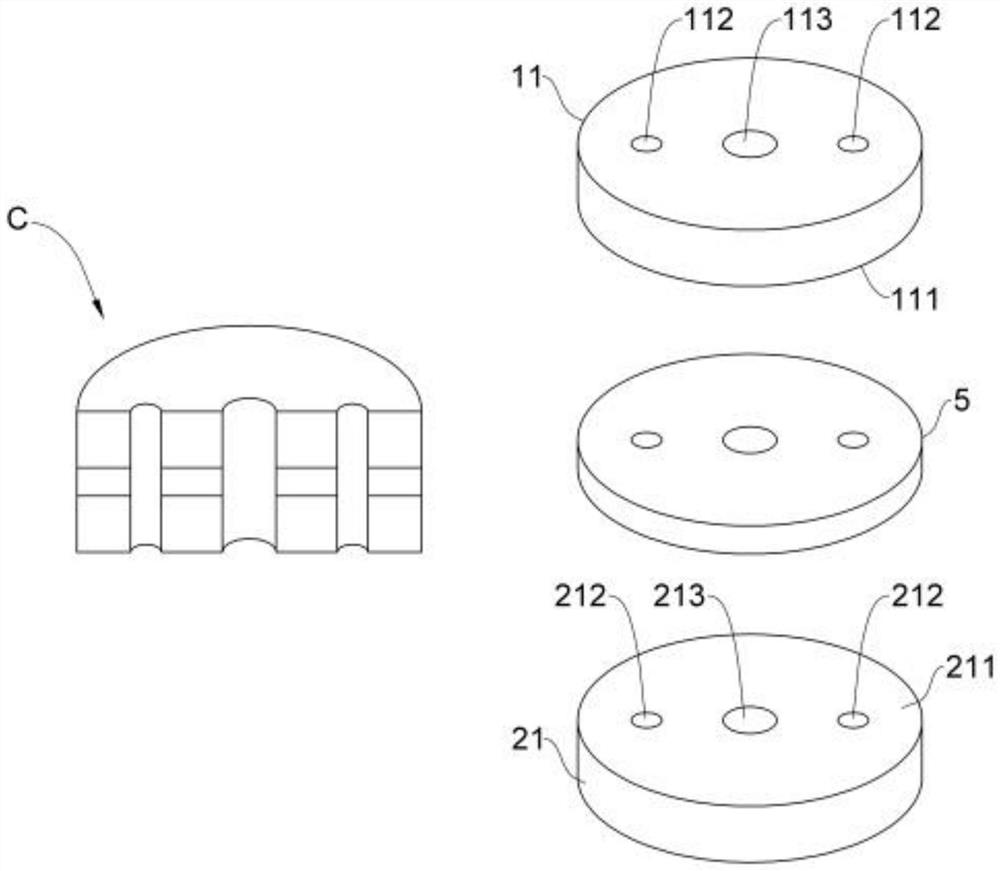

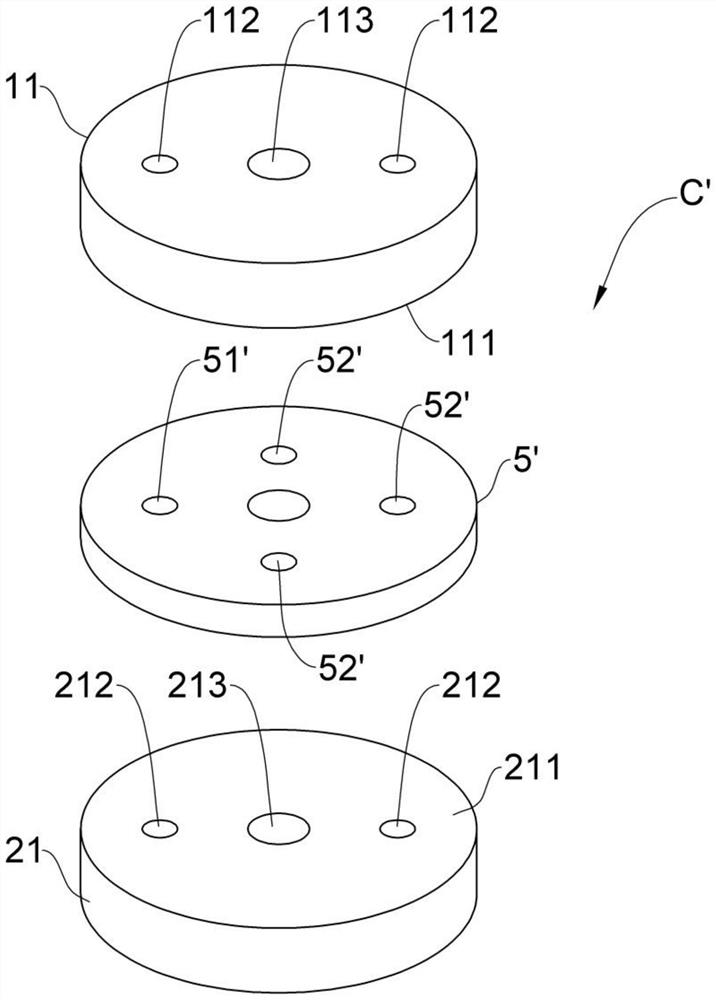

[0032] figure 1 The wafer support seat of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com