Vacuum automatic packaging method used for dye sensitization solar energy cell

A solar cell and dye sensitization technology, which is applied in the field of dye-sensitized solar cell production technology, can solve the problems of poor packaging automation and repeatability, complex packaging process, and increased packaging difficulty, so as to improve the packaging yield and product life , strong adhesion performance, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

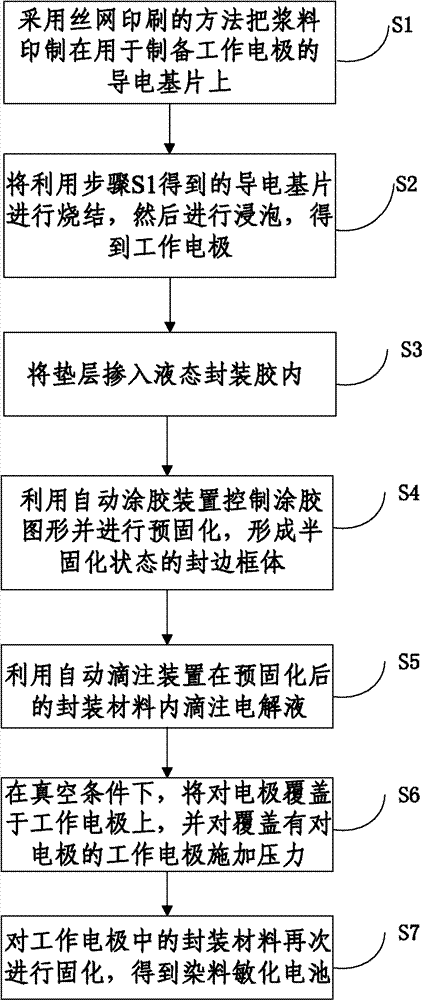

[0039] Such as figure 1 shown, and refer to Figure 2-5 , the method of the embodiment of the present invention includes the following steps:

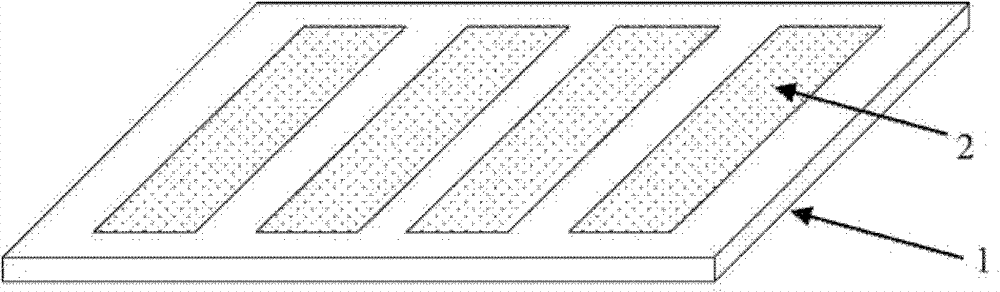

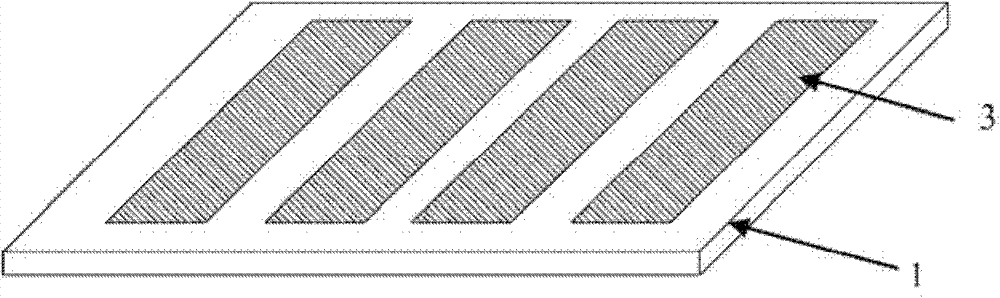

[0040] S1. Using screen printing technology to print TiO 2 The nanoparticle paste is printed on the conductive substrate (preferably F-doped tin oxide conductive glass (FTO conductive glass 1)) used to prepare the working electrode, so that the TiO 2 The nanoparticle paste was printed as several isolated TiO 2 Rectangular sheet film (may be referred to as TiO 2 film). TiO on each conductive substrate 2 Leave a gap between the films (for figure 2 The space between the four films) for easy packaging.

[0041] Among them, befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com